2 process variables mapping, Process variables mapping -5, Showing that a process variable is not assigned – Yokogawa Wireless Temperature Transmitter YTA510 User Manual

Page 12

IM 01C50T03-01E

3-5

3. OPERATION

DATA

DIAG

PRNT

ESC

PARAM

D10:SENSOR1 TYPE

Pt200 (IEC751)

D20:SENSOR WIRE

3 WIRE

D40:SENSOR1 TEMP

23.56 degC

ESC

SET

D10:SENSOR1 TYPE

Pt200 (IEC751)

TYPE B (IEC584)

TYPE W3(ASTM988)

TYPE W5(ASTM988)

TYPE E (IEC584)

TYPE J (IEC584)

TYPE K (IEC584)

TYPE L(DIN43710)

TYPE N (IEC584)

TYPE R (IEC584)

TYPE S (IEC584)

TYPE T (IEC584)

TYPE U(DIN43710)

Pt100 (IEC751)

Pt200 (IEC751)

Pt500 (IEC751)

JPt100 (JIS)

Ni120 (STI INC)

Cu (SAMA RC21-4)

ohm

mV

Non Connection

ESC

SET

D20:SENSOR1 WIRE

3 WIRE

<3 WIRE >

<4 WIRE >

<2 WIRE >

<1>

<2>

<3>

F0302.EPS

●

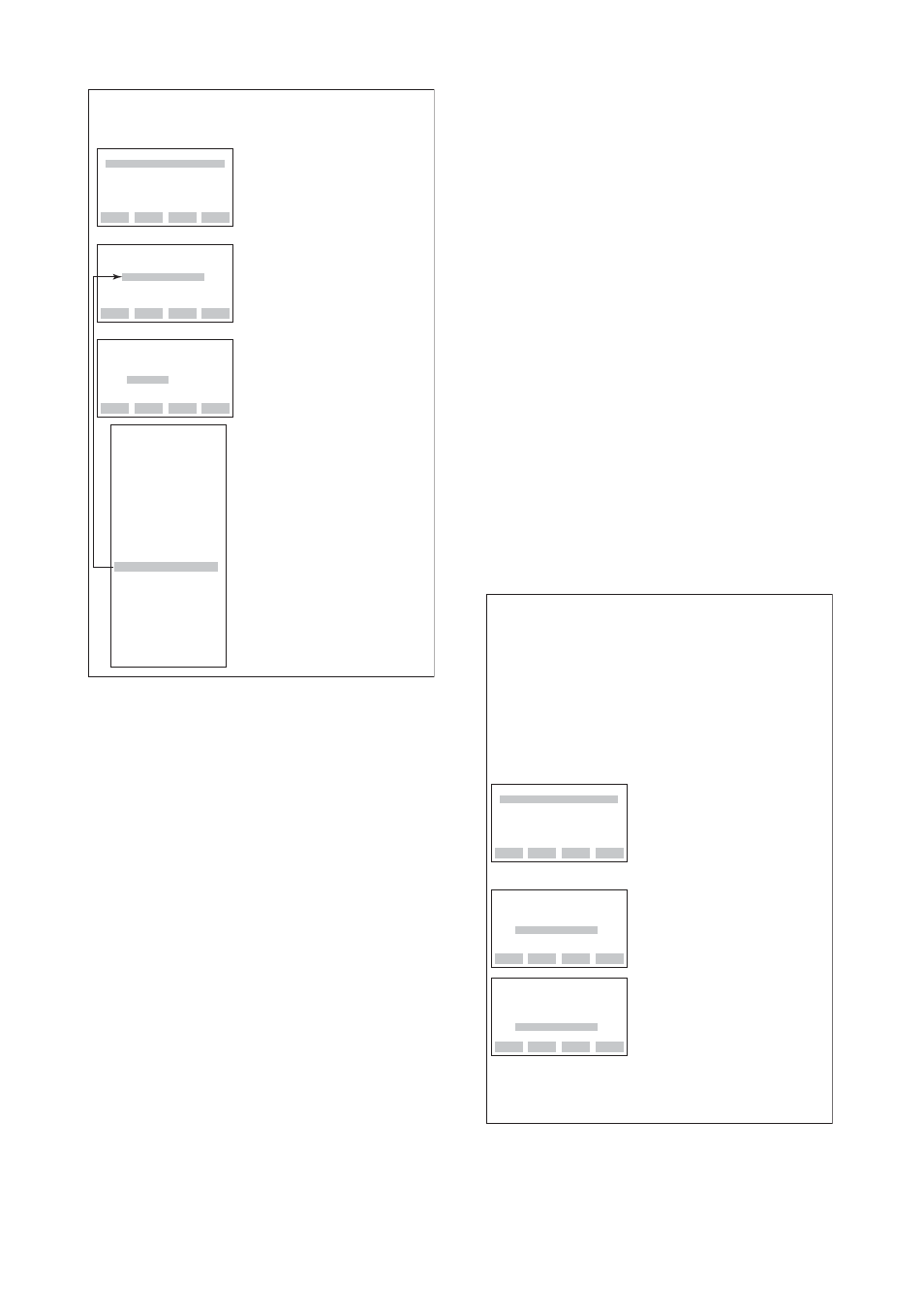

Example: Set Pt 100 and 4-wire type to Sensor1.

(model YTA320)

1. Select D: SET SENSOR1 to go

to the screen (1).

2. Select “D10” and press

[ENTER] to go to the

screen (2).

3. Select “Pt100” and press

[ENTER] twice.

4. Check that “Pt100” has been

set and press [OK].

5. To set the number of wire

connections, select

D20 and press [ENTER].

6. Select “4 WIRE” and press

[ENTER] twice.

7. Press [OK].

Note: D40 indicates input values of

the sensor based on the

settings at D10 and D20.

3.2.2

Process Variables Mapping

Process variable mapping;

B10: PV is, B20: SV is, B30: TV is, B40: 4V is

Process variables can be assigned as the primary

variable(PV), the secondary variable(SV), the tertiary

variable(TV), and the quaternary variable(4V). The PV

always outputs a 4 to 20mA DC analog signal corre-

sponding to Lower Range Value and Upper Range

Value. Mapping process variables to the SV, TV, and

4V is optional.

The following items can be mapped as the process

variables.

Sensor1

: Sensor1 input value.

Sensor2

: Sensor2 input value.

DIFFERENCE

*1,*2,*4

: Difference between

Sensor1 and Sensor2.

(Sensor1-Sensor2 or

Sensor2-Sensor1; speci-

fied in B05: SET DIFF)

AVERAGE

*1,*4

: Average of Sensor1 and

Sensor2.

[(Sensor1 + Sensor2)/2]

Sensor1-Term

*4,*5

: Difference between

Sensor1 and terminal

temperature

Sensor2-Term

*1,*4,*5

: Difference between

Sensor2 and terminal

temperature

Terminal Temp

: Terminal temperature

Not used

*3

: Showing that a process

variable is not assigned.

*1: This item is displayed only when the YTA320 2-input

temperature transmitter is used.

*2: The setting in B05 applies to the PV, SV, TV, and 4V.

*3: “Not used” is not displayed for B10 since the PV

requires process variable mapping.

*4: When this item is selected, the sensor types to be set

for D10(Sensor1) and E10(Sensor2) should be

selected from any one of the following three groups;

Temperature sensor(T/C and RTD), DC voltage or

resistance. The combination(for example, temperature

sensor and DC voltage input) would cause an incorrect

computation due to the different unit system and is not

allowed.

*5: When this item is selected, DC voltage and resistance

input should not be set for D10(Sensor1) or

E10(Sensor2).

F0303.EPS

DATA

DIAG

PRNT

ESC

PARAM

B05:SET DIFF

Sensor1-Sensor2

B10:PV is

Sensor1

B11:PV UNIT

degC

ESC

SET

B05:SET DIFF

Sensor1-Sensor2

ESC

SET

B10:PV is

Sensor1

1. Set the content of

“DIFFERENCE” for the

difference between Sensor1

and Sensor2.

Select B05: SET DIFF and

press [ENTER]

2. Select “Sensor2 - Sensor1” and

press [ENTER] twice.

3. Press [OK].

4. Select B10: PV is and press

[ENTER] for PV mapping.

5. Select “DIFFERENCE” and

press [ENTER] twice.

6. Press [OK].

●

Example: Use two temperature sensors to map the

difference (Sensor2-Sensor1) between Sensor1

and Sensor2 to the PV (the primary variable).

Before mapping the process variable, complete the

setting of the temperature sensor to be connected

to Sensor1 and Sensor2.

Sensor1 setting: D10: SENSOR1 TYPE, D20:

SENSOR1 WIRE

Sensor2 setting: E10: SENSOR2 TYPE, E20:

SENSOR2 WIRE

If the temperature sensor is correctly connected to Sensor1

and Sensor2,

the setting content is reflected on A10: PV.