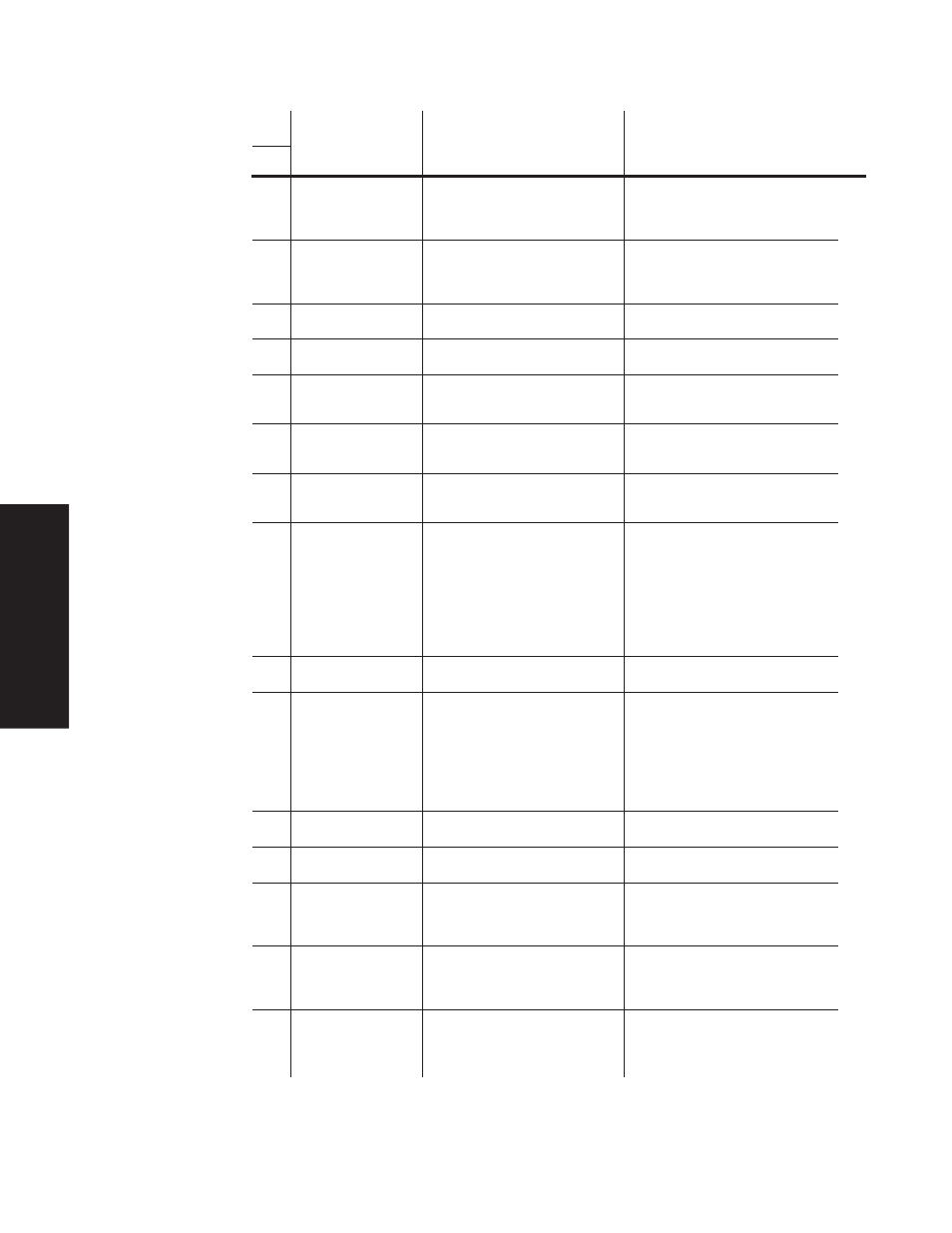

Dual channel controller prompt table, Table 7.10, Rpa to sys – Watlow Series 988 Family User Manual

Page 68

Name

Description

Read (?) and/or Write (=) Syntax

Range

data.1

data.2

Modbus

Address

Dual Channel Controller Prompt Table

996, 997,

998

, 999

7.10

Data Communications with the Watlow Series 988 Family

Command Summary Series 996-999, Chapter 7

RPA

Ramping Initiation

?

0 = off

1100

Channel A

=

1 = On startup

2 = On startup and set point change

Default: 0

RPB

Ramping Initiation

?

0 = off

1104

Channel B

=

1 = On startup

2 = On startup and set point change

Default: 0

RTA

Ramp Rate

?

0 to 9999°/minute

1101

Channel A

=

Default: 100°/minute

RTB

Ramp Rate

?

0 to 9999°/minute

1105

Channel B

=

Default: 100°/minute

RTD1

RTD Calibration

?

0 = JIS

609

Curve Input 1

=

1 = DIN

Default: 1

RTD2

RTD Calibration

?

0 = JIS

619

Curve Input 2

=

1 = DIN

Default: 1

SIL3

Alarm 3 Silence

?

0 = off / disabled

739

=

1 = on / enabled

Default: 0

SRNB Serial Number

?

xxxx =

2

Bottom Display

0000 to 9999

Read the six-digit unit

serial number in two

segments,

"SNxx" and "xxxx,"

i.e., as in the

upper and lower

front panel displays.

SRNT

Serial Number

?

SNxx =

1

Top Display

00 to 99

SOFT

Software Revision

?

0 = Rev A

7 = Rev H

4

1 = Rev B

8 = Rev I

2 = Rev C

9 = Rev J

3 = Rev D

10 = Rev K

4 = Rev E

11 = Rev L

5 = Rev F

12 = Rev M

6 = Rev G

13 = Rev N

etc.

SPA

Set Point Channel A ?

RL1 to RH1

300

=

Default: per IN1 and hardware

SPB

Set Point Channel B ?

RL2 to RH2

319

=

Default: per IN1 and hardware

SP2A

Set Point 2

?

RL1 to RH1

309

Channel A

=

Default: per input range

Heat/Heat or

Cool/Cool Only

SP2B

Set Point 2

?

RL2 to RH2

328

Channel B

=

Default: per input range

Heat/Heat or

Cool/Cool Only

SYS

Lockout System

?

0 = No lockout

1306

Menu

=

1 = Read only

2 = No read or write

Default: 0

Table 7.10 -

RPA to SYS

ç

CAUTION:

Avoid writing <=>

continuously,

such as ramping

set points or

repetitive loops, to

the Series 996-999

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to

processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these com-

mands is deter-

mined by the

DEC1, DEC2, IN1

or IN2 setting.

(This does not

apply to Modbus

Protocol.)