Series 965 quick reference, 41 quick reference, 41 quick reference sheet (perforated) – Watlow Series 965 User Manual

Page 41: Quick reference sheet 41, Series 965, Quick reference, Error codes, Alarms keys & displays

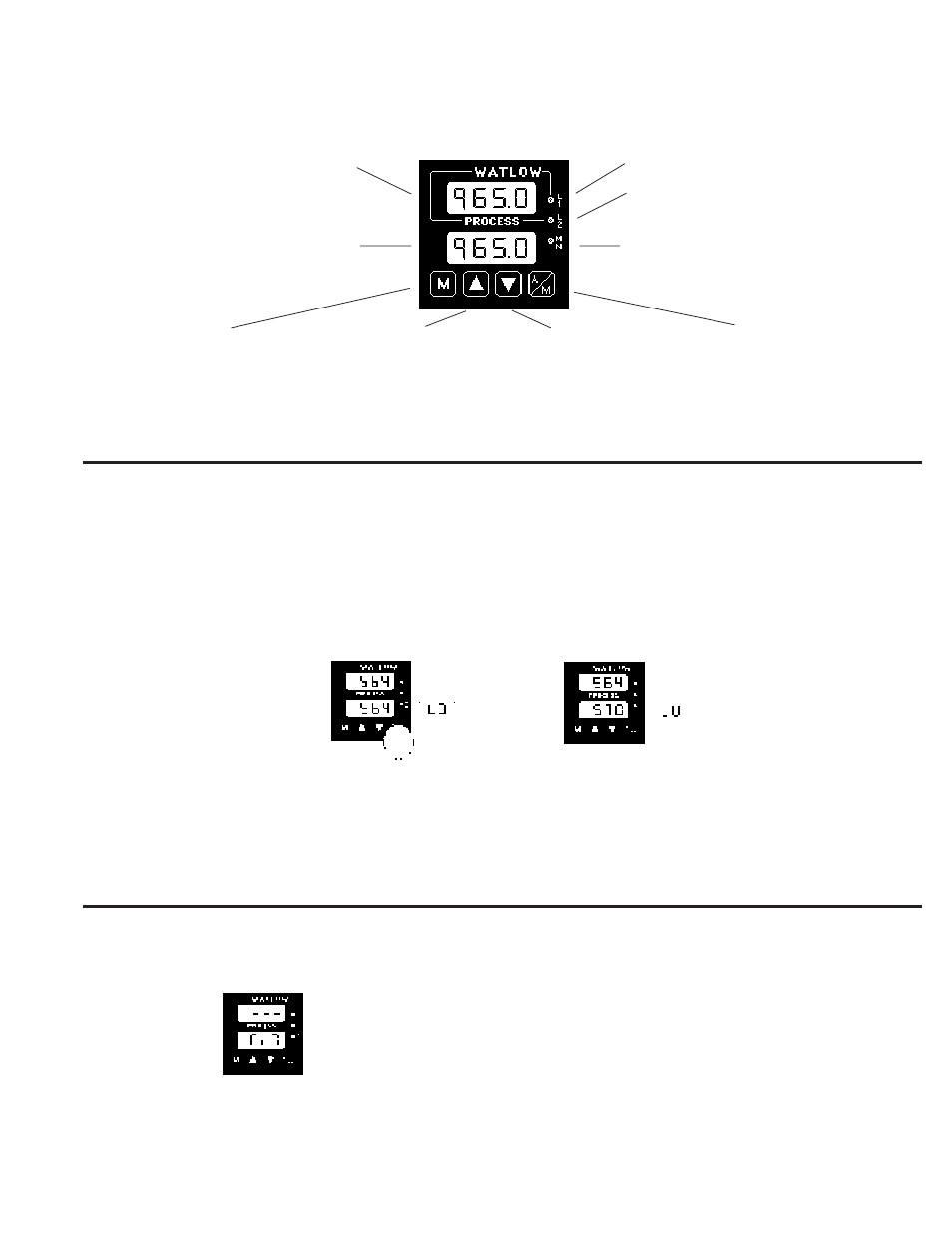

A/M Key: Press once to clear latched

alarms and toggles between Auto and

Manual. If pressed within 5 seconds it

changes from Auto to Manual or vice versa.

While in Manual, percent power is in the

lower display.

MN: Lit when in manual operation. Press A/M twice

to enter Automatic. When blinking, press A/M to

toggle between Auto and Manual. After 5 seconds

without key activations it returns to its previous state.

MODE Key: Steps the control

through the operating menu,

also, in the Auto mode, new

data is self entering in 5 sec-

onds.

Up-arrow/Down-arrow Keys: When pressed simultaneously for 3

seconds, the Setup Menu appears displaying the LOC parameter.

Continue to press the UP/DOWN keys, and the Calibration menu

appears.

Up-arrow Key: Increases

the value of the displayed pa-

rameter. New data is self

entering in 5 seconds.

Down-arrow Key: Decreases

the value of the displayed pa-

rameter. New data is self enter-

ing in 5 seconds.

Lower Display: Red or green, four digit LED

display, indicating the set point, output value,

parameters for data in the upper display, or error

and alarm codes.

L1: When lit it indicates Output 1 is energized.

L2: When lit it indicates when Output 2 is active. This

output can be configured as a control or alarm output.

Upper Display: Red or green, LED display,

indicating either process actual temperature, the

operating parameter values, or an open sensor.

Er 5 - Non volatile checksum error

The nonvolatile memory checksum discovered a checksum error. Unless

a momentary power interruption occurred while the unit was storing data,

the nonvolatile memory is bad. Call the factory.

Er 6 - A/D underflow error

The A/D circuit is underrange. An open or reversed polarity sensor is the

most likely cause. Check the sensor; if the connection is good and

functions properly, call the factory. The A/D underrange voltage is too low

to convert an A/D signal. Make sure the In parameter matches your

sensor and the DIP switches are set accordingly.

Er 7 - A/D overflow error

The A/D circuit is overrange. An open or reversed polarity sensor is the

most likely cause. Check the sensor; if the connection is good and the

sensor functions properly, call the factory. The A/D overrange voltage is

too high to convert an A/D signal. Make sure the In parameter matches

your sensor and the DIP switches are set accordingly.

Four dashes, "- - - -" or a negative number, in the upper display indicate a

Series 965 error. The error code is visible in the lower display.

Er 2 - Sensor underrange error (For RTD units only)

The sensor input generated a value lower than the allowable signal range,

or the A/D circuitry malfunctioned. Enter a valid input. Make sure the In

parameter matches your sensor and DIP switch setting. Refer to the table

below for the appropriate input type and range.

Er 4 - Configuration error

The unit's microprocessor is faulty; call the factory.

Error Codes

Process Alarm sets an absolute temperature. When the process

exceeds that absolute temperature limit an alarm occurs. The process

alarm set points may be independently set high and low. Under the

Setup menu, select the type of alarm output with the Ot2 parameter.

PrA = Process alarm

Pr = Process alarm with no alarm message displayed

Deviation Alarm: Alerts the operator when the process strays too far

from set point. The operator can enter

independent high and low alarm settings.

The reference for a deviation alarm is set

point. Any change in set point causes a

corresponding shift in the deviation alarm.

Under the Setup menu, select the type of

alarm output with the Ot2 parameter.

dEA = Deviation alarm

dE = Deviation alarm with no alarm

message displayed

Alarm Silencing is available with the deviation alarm. When SIL is

selected as "on," the operator must manually disable the alarm by

pressing the A/M key once on initial power up (in either the latching or

non-latching mode). Alarm silencing disables the alarm output relay.

However, the L2 LED (also the lower display when Ot2 = dEA) shows

an alarm condition until the process value is within the "safe" region of

the deviation alarm band. Once the process value crosses into the

"safe" region, both a latching or a non-latching alarm is ready. Any

future deviation outside this safe band triggers an alarm.

Both alarms can be latching or non-latching. When the alarm

condition is removed a non-latching alarm automatically clears the

alarm output. You must manually clear a latching alarm before it will

disappear.

Flashing LO or HI in the lower display

indicates an alarm when Ot2 = PrA or

dEA. The lower display alternately

shows information from the current

parameter and a LO or HI alarm mes-

sage at one second intervals. The

alarm output is de-energized, L2 is lit.

To clear an alarm...

• First correct the alarm condition, then...

• If the alarm is latching...

Clear it manually; press the A/M key once as soon as the

process temperature is inside the HSA parameter alarm limit.

• If the alarm is non-latching...

The alarm clears itself automatically as soon as the process

temperature is inside the HSA parameter alarm limit.

Press once

to clear

a latched

and

corrected

alarm.

Alarms

Keys & Displays

Series 965

Quick Reference

Use this page as a quick reference for the Series 965. Tear along the perforation.