Wiring to the dio connector – Proface LT3300 - 5.7 All-in-One HMI" User Manual

Page 9

9

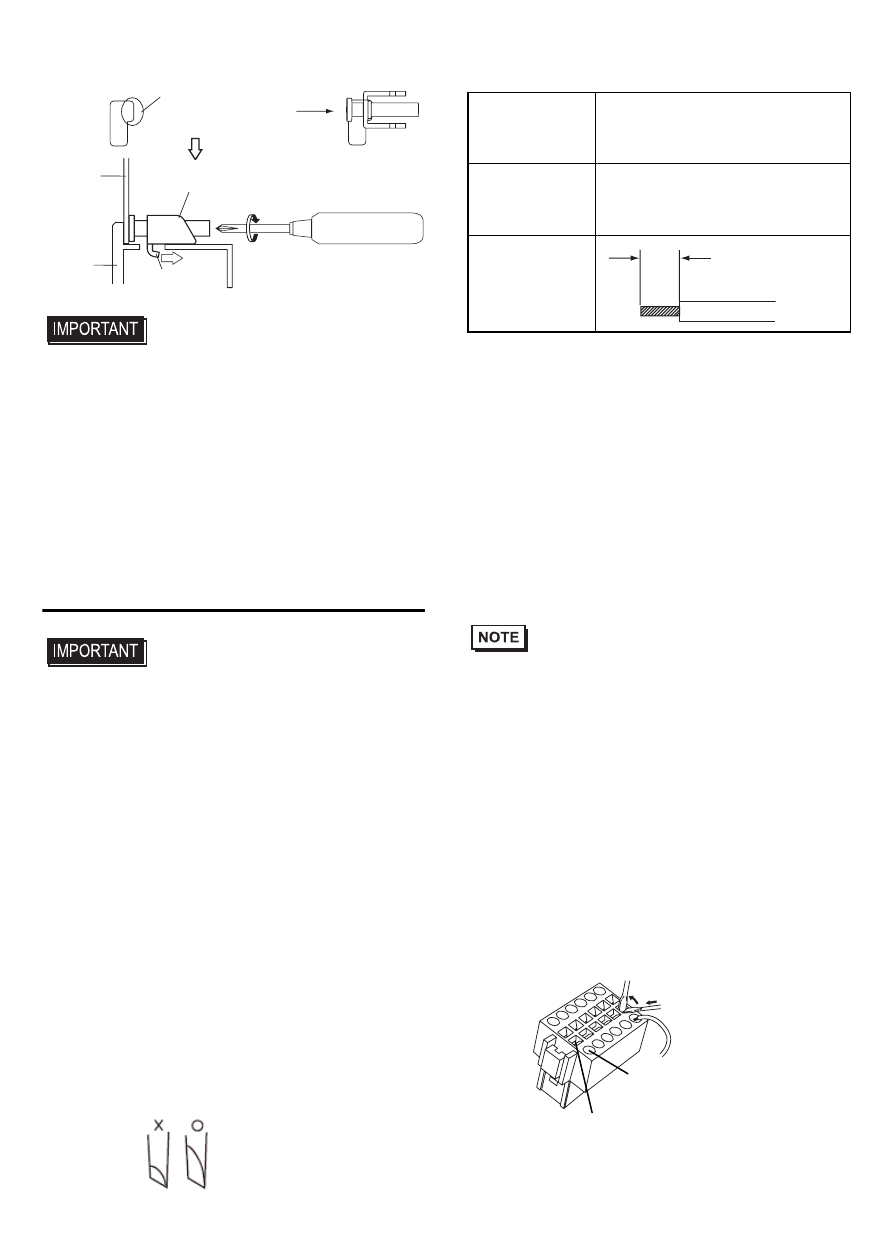

• Tightening the screws with too much

force can damage the LT unit’s plastic

case.

• The necessary torque is 0.5N

•m.

• Be sure to insert installation fasteners

in the recessed portion of a installation

fasteners hole. If the fasteners are not

correctly attached, the LT unit may shift

or fall out of the panel.

3.

Wiring to the DIO Connector

• Be sure to remove the DIO Connector

from the LT unit prior to starting wiring.

Failure to do so may cause an electric

shock.

Items Required to Wire Connectors

Screwdriver

Recommended type: 1891348-1

If another manufacturer is used, be sure the

part has the following dimensions:

point depth: 1.5mm [0.06in.]

point width: 2.4mm [0.09in.]

Point shape should be DIN5264A, and meet

Security Standard DN EN60900.

Also, the screwdriver’s tip should be flat as

indicated in order to access the narrow hole

of the connector:

DIO Cable Specifications

Connecting the DIO Cable

(1) Insert a flathead screwdriver, at an angle,

into the tool insertion hole (square-

shaped hole) of the connector.

(2) When inserting the flathead screw driver,

be sure that it is perpendicular to the cen-

ter division wall.

• Make the insertion distance of the flathead

screwdriver approximately 4 mm. Insert-

ing forcefully may break the inside of the

connector and will a cause of contact

defect.

Also, do not turn the flathead screwdriver

while the tip is inside of the tool insertion

hole (square-shaped hole).

(3) The adjacent wire insertion hole (round-

shaped hole) will be in an open state.

With the flathead screwdriver still

inserted, insert the wire into the wire

insertion hole (round-shaped hole).

Insertion Slot Recess

Hook the fastener

on the Recess,

Panel

Installation Fastener

Hook

and secure the fastener

on the panel with a

screw.

LT

Panel

Completed View

Screwdriver Tip

Shape

DIO Cable

Diameter

AWG24 to 18

UL1015 or UL1007

Conductor

Type

Stranded Wire

*1

*1 If the Conductor’s end (individual) wires are

not twisted correctly, the end wires may either

short against each other, or against an

electrode.

Conductor

Length

7 mm

[0.28in]

Screwdriver

Wire

Wire insertion hole

(Round-shaped hole)

Tool insertion hole

(Square-shaped hole)