Troubleshooting, Caution – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 40

E-7

TROUBLESHOOTING

E-7

POWER WAVE

®

ADVANCED MODULE

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

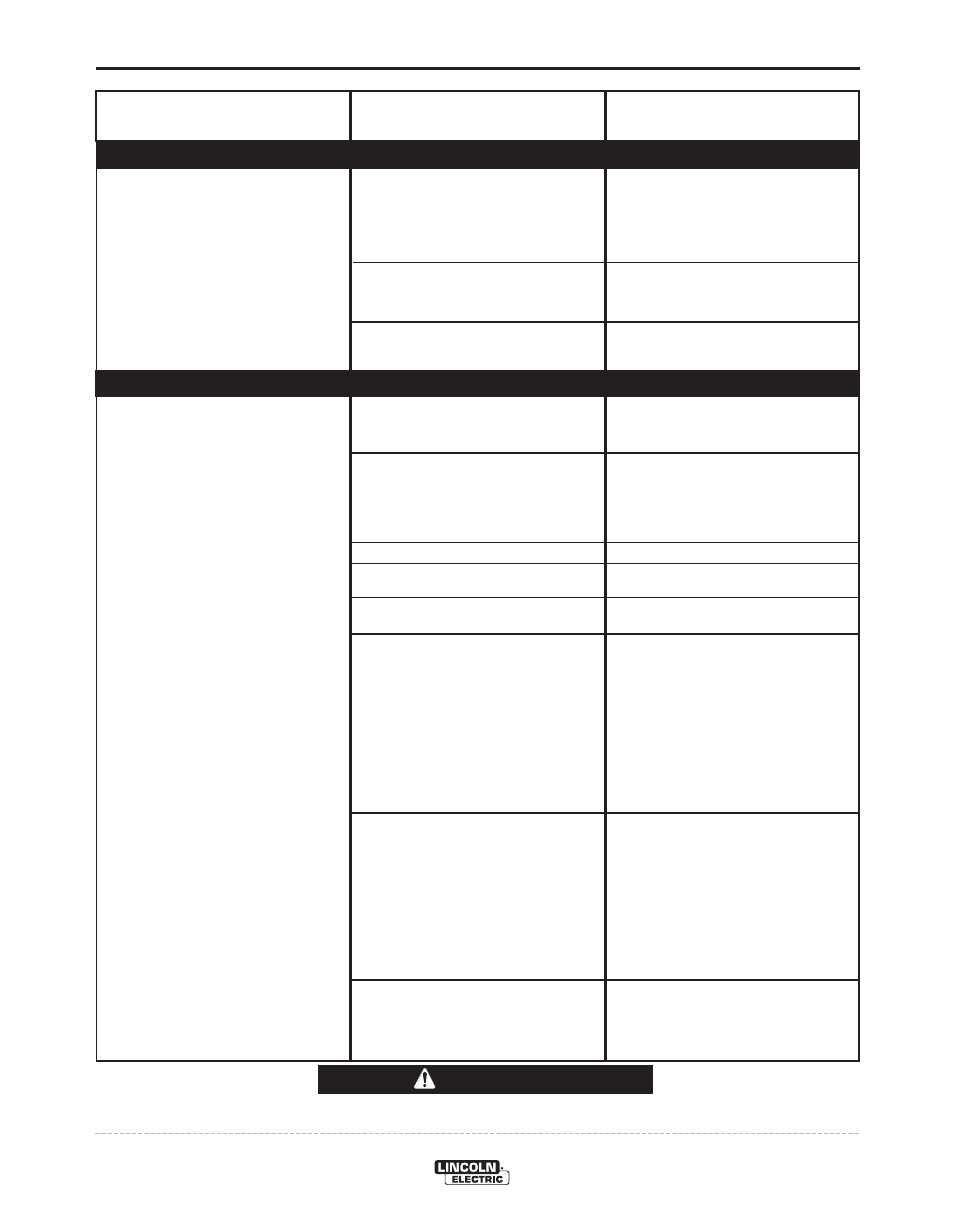

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED

COURSE OF ACTION

Thermal error indication on Advanced Module

(error 36).

General degradation of weld performance.

1. Improper fan operation.

2. Switch PC board thermostat.

3. Open thermostat circuit.

1. Wire feed problem.

2. Cable Connections.

3. Loss of, or improper Shielding Gas.

4. Verify weld mode is correct for process.

5. Machine calibration.

6. STT Process ONLY: Excessive cable

inductance or STT snubber resistor failure.

7. AC Process ONLY: Excessive cable induc-

tance or snubber discharge resistor failure.

8. Sense Lead Connections

1. Check for proper fan operation. (Fans typi-

cally run whenever output power is on.)

Check for material blocking intake or

exhaust louvers, or for excessive dirt clog-

ging cooling channels in machine.

2. After machine has cooled, reduce load, duty

cycle, or both. Check for material blocking

intake or exhaust louvers and heat sink fins.

3. Check for broken wires, open connections or

faulty thermostat in the Advanced Module.

1. Check for feeding problems. Check actual

WFS vs. preset. Verify proper wire drive and

gear ratio has been selected.

2. Check for bad connections, excessive loops

in cable, etc.

NOTE: The presence of heat in the external

welding circuit indicates poor connections or

undersized cables.

3. Verify gas flow and type are correct.

4. Select the correct weld mode for the applica-

tion.

5. Verify the calibration of the power source

output current and voltage.

6. Excessive cable inductance or STT snubber

resistors failure can cause the transient volt-

age to exceed the safe operating threshold

on the AC Switch PC board. Under these

conditions the AC Switch PC board faults to

protect itself.

Follow recommended cable guidelines to

minimize the inductance, and inspect the

snubber resistor circuit for damage.

7. Excessive cable inductance or snubber dis-

charge resistors failure can cause the oper-

ating voltage to exceed the safe operating

threshold on the AC Switch PC board. Under

these conditions the AC Switch PC board

faults to protect itself.

Follow recommended cable guidelines to

minimize the inductance, and inspect the

snubber resistor circuit for damage.

8. Verify that the voltage sense pigtail is con-

nected to the power source. If remote volt-

age sens leads are being used, verify con-

nection.

basiC maChine Problems

weld and arC quality Problems