Installation – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 12

A-6

INSTALLATION

POWER WAVE

®

ADVANCED MODULE

A-6

remote SenSe LeaD ConneCtIonS

Voltage Sensing overview

Certain welding process requires the use of remote

voltage sense leads to more accurately monitor the

conditions of the arc. These leads originate in the

power source, and are connected and configured

through the Advanced Module. Consult the connec-

tion diagrams included in this manual for detailed

information.

note:

OtherprocessesrunthroughtheAdvancedModuledo

not necessarily require sense leads, but will benefit

from their use. Consult the power source instruction

manualforrecommendations.

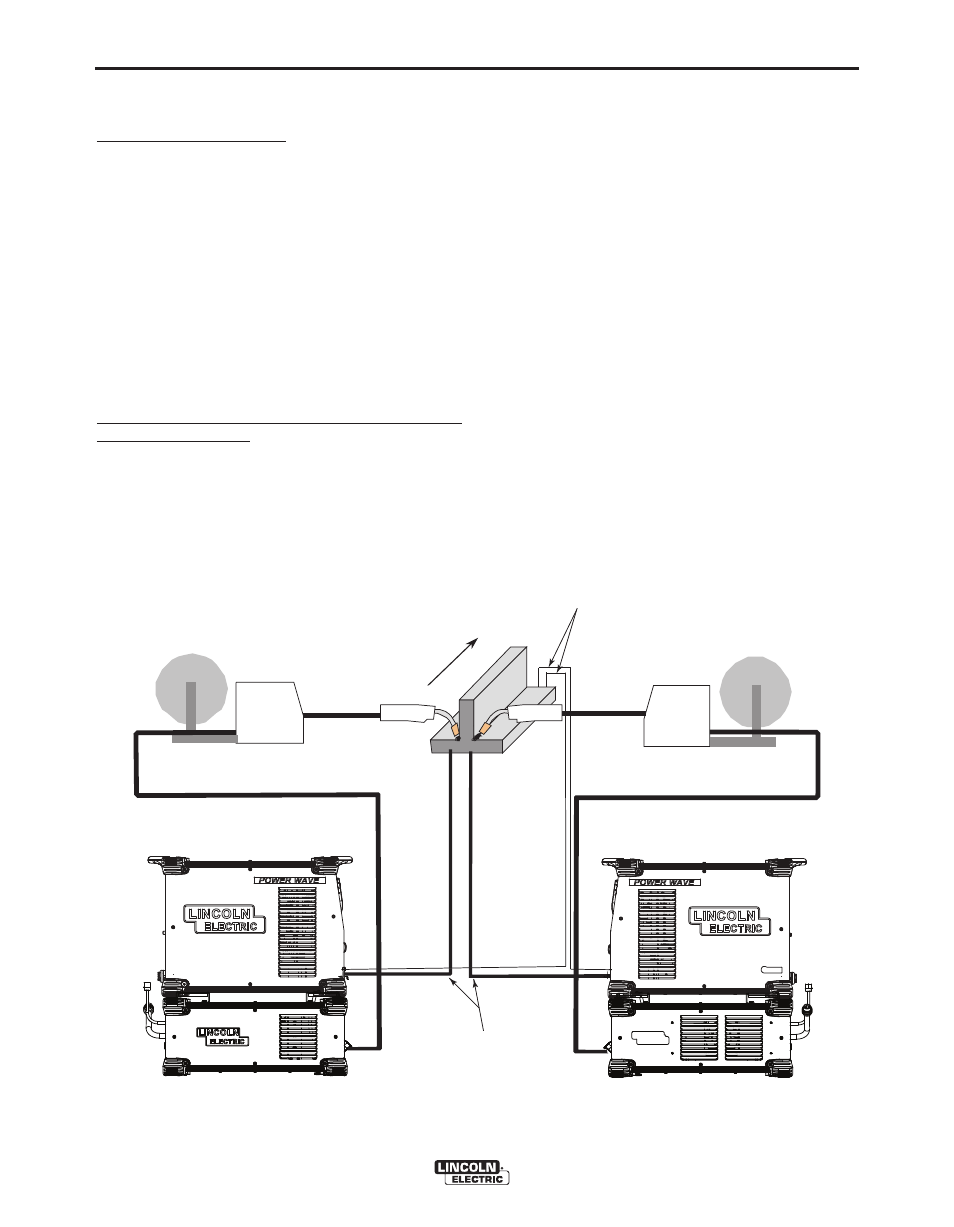

general Voltage Sensing Considerations for

multiple arc Systems

Special care must be taken when more than one arc

isweldingsimultaneouslyonasinglepart.Theplace-

mentandconfigurationofremoteworkvoltagesense

leadsiscriticaltotheproperoperationofmultiplearc

ACandSTT

®

applications.

RECOMMENDATIONS:

• Position the sense leads out of the path of the

weld current. Especially any current paths com-

mon to adjacent arcs. Current from adjacent arcs

can induce voltage into each others current paths

that can be misinterpreted by the power sources,

and result in arc interference.

• For longitudinal applications, connect all work

leads at one end of the weldment, and all of the

work voltage sense leads at the opposite end of

the weldment. Perform welding in the direction

away from the work leads and toward the sense

leads.

(See Figure a.5)

DIRECTION

OF TRAVEL

CONNECT ALL

WORK LEADS AT

THE BEGINNING

OF THE WELD.

CONNECT ALL SENSE

LEADS AT THE END

OF THE WELD.

FIgure a.5