Installation, Warning – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 10

A-4

INSTALLATION

POWER WAVE

®

ADVANCED MODULE

A-4

Ce machines:

S350andS500CEPowerSourcehaveanArcLinkoutput

receptaclelocatedonthecasefront.TheArcLinkwirefeeder

canbeattachedtoeitherthereceptacleonthepowersource

casefrontorAdvancedModulecaseback.

eLeCtroDe anD worK ConneCtIonS

Connect the positive and negative input connections

andelectrodeandworkoutputcablespertheconnec-

tion diagrams included in this document. Size and

routethecablespertable a.1.

outPut PoLarItY

The output polarity is automatically configured based

on the selected weld mode. There is no need to

reverseoutputcables.

Feeder should always be connected to GMAW elec-

trodestud.

Workpiece should alway be connected to the work

stud.

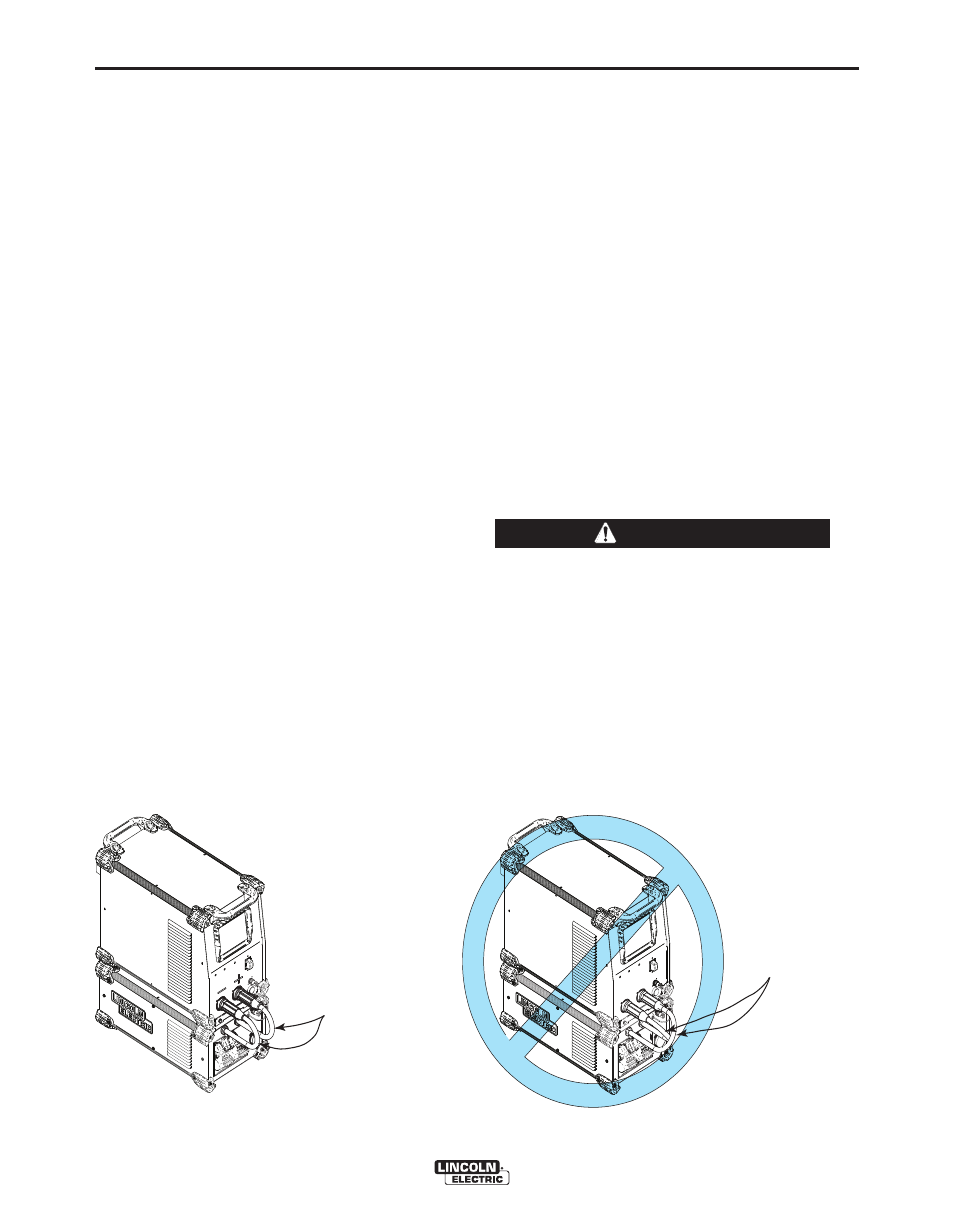

never reverse the polarity at the input of the

advanced module (Do not connect the negative

stud of the power source to the positive input of

the advanced module). this may result in damage

to the advanced module! (See Figure a.3 for

Correct Polarity)

------------------------------------------------------------------------

For additional Safety information regarding the elec-

trode and work cable set-up, See the standard

“SaFetY InFormatIon” locatedinthefrontofthe

InstructionManuals.

SPeCIaL InStruCtIonS

Ce machines:

A special ArcLink

®

and Differential I/O receptacle kit

isprovidedwiththeAdvancedModuleforinstallation

into the host power source. Follow the instructions

provided with the kit. (reference instruction sheet

M22499andM22499-1)

K2823-1(Code 11589)

Some earlier vintage S350 power sources may not

include a 6 pin Differential I/O receptacle. If the

receptacle is not present on the host power source,

contact the Lincoln Electric Service Department to

obtainanS350/STTRetrofitKit(S28481).

ConneCtIon Between aDVanCeD

moDuLe to arCLInK® wIre FeeDerS

(K1543 or K2683 arCLInK® ControL

CaBLe)

TheK2912-1AdvancedModuleincludesanArcLink

®

output receptacle for connection to compatible wire

feeders.

The control cable consists of two power leads, one

twisted pair for digital communication, and one lead

for electrode voltage sensing. The 5 pin ArcLink

®

receptacle is located on the lower rear portion of the

Advanced Module. The control cable is keyed and

polarizedtopreventimproperconnection.Bestresults

willbeobtainedwhencontrolcablesareroutedsepa-

ratefromtheweldcables,especiallyinlongdistance

applications. The recommended combined length of

theArcLink

®

controlcablenetworkshouldnotexceed

200ft.

WARNING

DO NOT REVERSE

INPUT CONNECTION

LEAD POLARITY

CORRECT

INPUT CONNECTION

LEAD POLARITY

FIgure a.3