Troubleshooting, Caution – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 39

E-6

TROUBLESHOOTING

E-6

POWER WAVE

®

ADVANCED MODULE

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

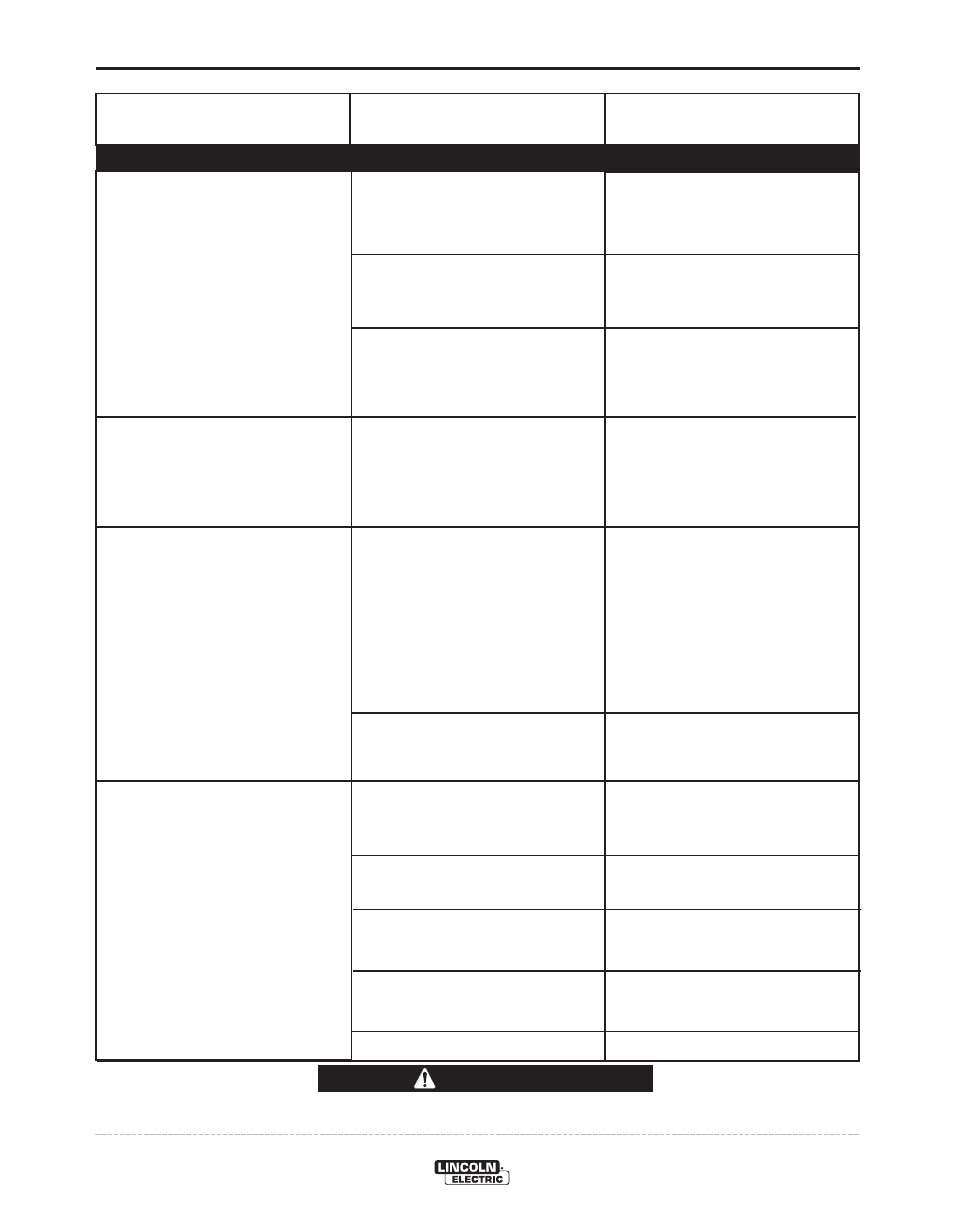

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Input fuses keep blowing

Machine will not power up (no lights

on power source, Advanced Module

or Wire Feeder).

No Status Light on Advanced Module

Machine won’t weld, when attached

to Advance Module.

1. Improperly sized input fuses.

2. Improper Weld Procedure requir-

ing output levels in excess of

machine rating.

3. Major physical or electrical dam-

age is evident in the power source

when the sheet metal covers are

removed.

1. No Input Power.

1. 40VDC input not present at

Advanced Module.

2. Malfunctioning Status LED.

1. Status Error.

2. Thermal Error.

3. 40VDC input not present at

Advanced Module.

4. Internal open circuit

5. Reversed input leads.

1. Make sure fuses are properly

sized. See installation section of

this manual for recommended

sizes.

2. Reduce output current, duty cycle,

or both.

3. Contact your local authorized

Lincoln Electric Field Service

facility for technical assistance.

1. Make sure input supply disconnect

has been turned ON. Check input

fuses. Make certain that the

Power Switch on the power

source is in the “ON” position.

1. Check ArcLink

®

cable. Verify

40VDC per wiring diagram.

• If wire feeder is functional and

connected through the Advanced

Module, suspect connection

issue in Advanced Module.

Verify condition of LED’s on AC

Switch PCB (viewable through

left side louvers).

2. Verify status LED is properly

installed and has not disengaged

from the lens.

1. Check LED’s on AC Switch PCB

to investigate cause of Status

Error.

2. See “Thermal error indiction...”

section.

3. See “No Status Light on

ADVANCED…” section.

4. Check for loose or broken connec-

tion in Advanced Module weld cir-

cuit.

5. Check polarity of input leads.

basiC maChine Problems