Operation, Caution – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 31

B-3

OPERATION

B-3

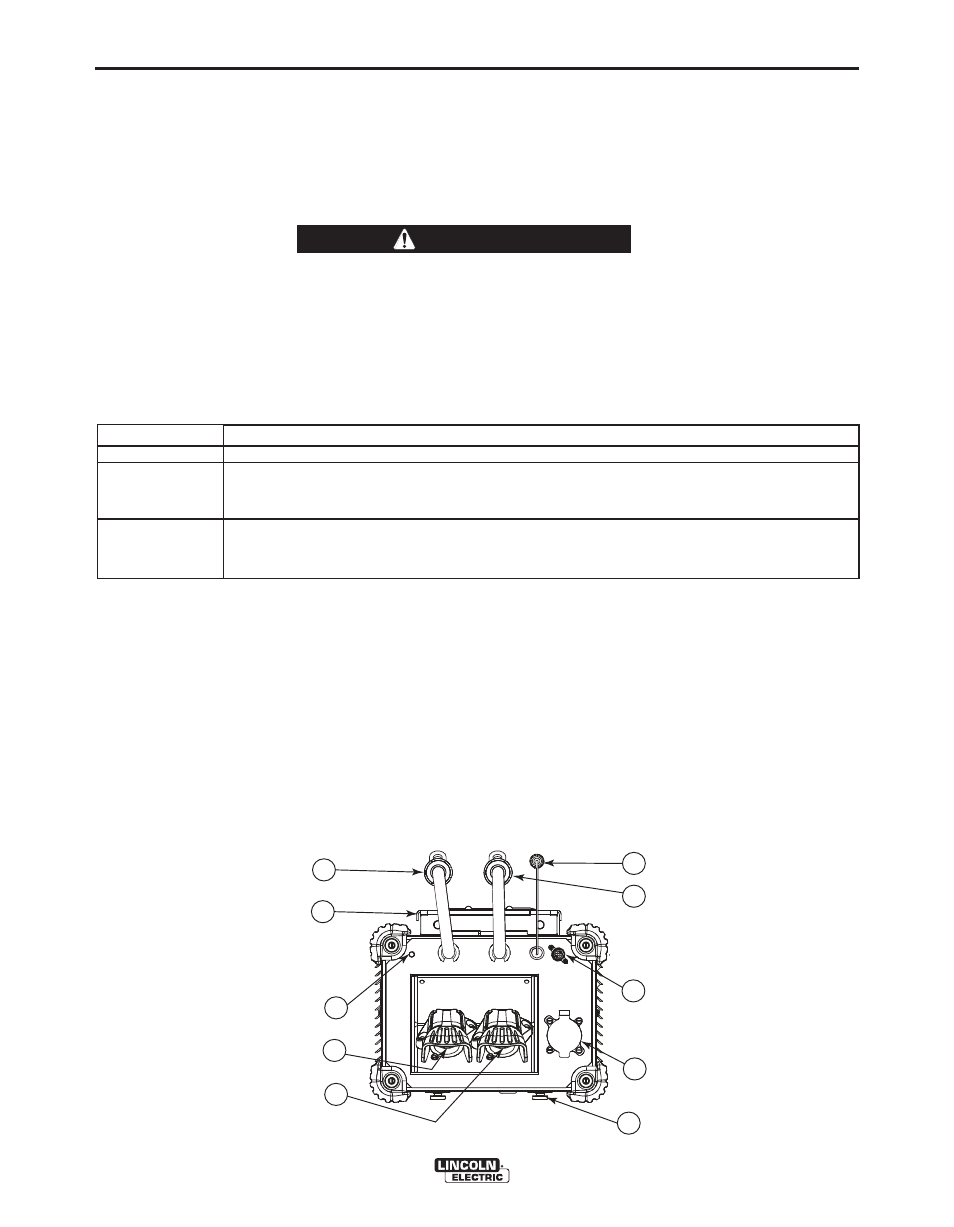

CASE FRONT DESCRIPTIONS

(See Figure B.1)

1. NEGATIVE – Connects to Negative output of power source.

2. POSITIVE – Connects to Positive output of power source.

3. VOLTAGE SENSE PIGTAIL- Provides voltage feedback to the power source from the module.

MUST BE CONNECTED TO PROVIDE ACCURATE VOLTAGE FEEDBACK, EVEN WHEN SENSING FROM

THE STUDS.

4. POWER SOURCE MOUNTING BRACKET – Provides a quick and reliable union between power source and

module.

5. STATUS LED – Provides ArcLink

®

status of Power Wave

®

Advanced Module.

Note: During normal power-up, the LED will flash green up to 60 seconds as the equipment performs self tests.

6. SENSE LEAD OUTPUT – Provides voltage feedback for remote electrode and work sense leads.

Note: The 67 pin in 4 pin connecter, located on power source case front is disconnected internally on the S350 CE.

7. WORK – Connects to workpiece, regardless of process..

8. GMAW ELECTRODE – Connects to feeder for GMAW welding, regardless of process.

9. GTAW/SMAW ELECTRODE – Connected internally to GMAW ELECTRODE, but also provides high frequen-

cy capability for TIG starting, provides solenoid controlled gas pass through.

10. POWER SOURCE MOUNTING FEET – Provides a quick and reliable union between the module and a cool-

er or cart.

POWER WAVE® ADVANCED MODULE

FIGURE B.1

LeD condition

Steadygreen.

Blinkinggreen.

Alternatinggreen

andred

.

Definition

Systemokay.Thepowersource,wirefeederandmodulearecommunicatingnormally.

Occursduringaresetandindicatesthepowersourceisidentifyingeachcomponentinthe

system.Thisisnormalforthefirst60secondsafterpower-up,orifthesystemconfiguration

ischangedduringoperation.

Non-recoverablesystemfault.Ifthepowersource,wirefeederormodulesstatusLEDare

flashinganycombinationofredandgreen,errorsarepresentinthesystem.Readtheerror

codebeforethemachineisturnedoff.

3

2

1

4

5

6

9

10

7

8

CAUTION