Operation, Recommended processes and equipment – Lincoln Electric IM10149 POWER WAVE ADVANCED MODULE User Manual

Page 30

B-2

OPERATION

B-2

RECOMMENDED PROCESSES AND

EQUIPMENT

RECOMMENDED PROCESSES

The Power Wave

®

Advanced Module is recommended for

all process supported by the host power source including,

but not limited to SMAW, GMAW, GMAW-P, GMAW-STT,

GTAW.

PROCESS LIMITATIONS

The Advanced Module is rated for 300 amps, 32 volts at a

100% duty cycle and 350 amps, 34 volts at a 40% duty

cycle rating. When connected to an S500 (CE) or R500

power source, the power source will acknowledge that the

Advanced module is connected and reduce the output capa-

bility to match that of the S350(CE) or R350.

The Power Wave

®

Advanced Module is designed to protect

itself from the excessive transient voltages associated with

highly inductive weld circuits. These high inductance circuits

may result in unsatisfactory performance, but will not dam-

age the module.

The Advanced Module is designed to be connected with

the proper polarity. If a negative electrode polarity

process such as Innershield is required, the switch will

automatically reconfigure the output of the Advanced

Module. If the input of the Advanced Module is reversed,

the module will protect itself and block output capability.

EQUIPMENT LIMITATIONS

The Power Wave

®

Advanced Module is intended for

use with compatible medium range “S” – series Power

Wave power sources such as the S350 and S500.

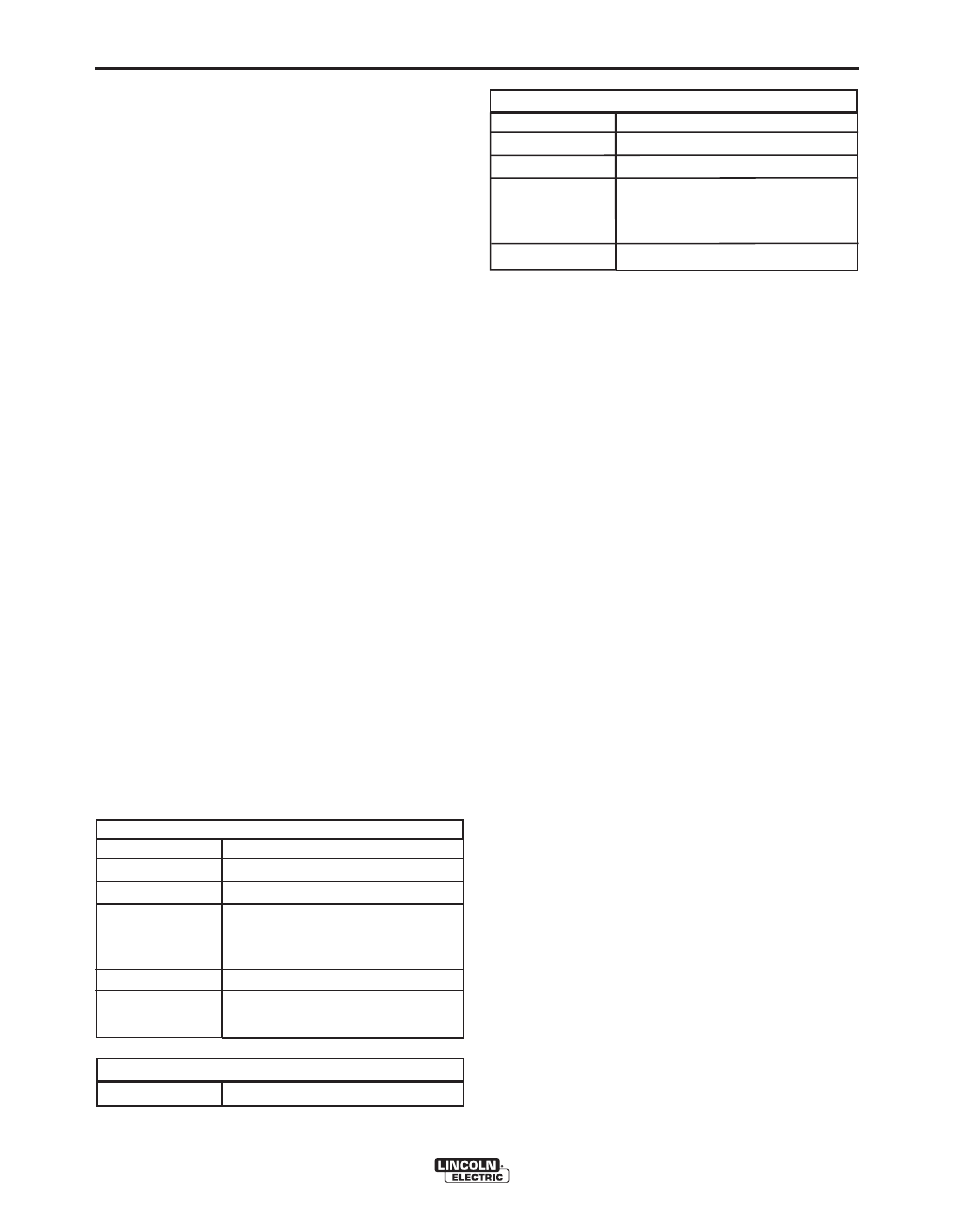

COMMON EQUIPMENT PACKAGES

POWER WAVE

®

ADVANCED MODULE

K2912-1

K2823-2

K14072-1

K1543-xx

K14050-1

AdvancedModule

PowerWave

®

S350(CE)

LF-45

ArcLink

®

Cable(5pin)–con-

nectswirefeedertopower

source.

CoolArc50

BaSIC PaCKage (Ce)

K2912-1

K2823-1

K2370-2

K1543-xx

K3086-1

K2212-2

K2536

AdvancedModule

PowerWave

®

S350

POWERFEED

®

-10M

ArcLink

®

Cable(5pin)–con-

nectswirefeedertopower

source.

CoolArc55

Python–watercooledpush

pullgun

POWERFEED

®

-25M

BaSIC PaCKage (StanDarD)

oPtIonaL wIre FeeDerS