Warning, Notice, Installation procedure using blind fasteners – WEATHER GUARD 1245 User Manual

Page 4: Step 12

- NOTICE -

Any modification or unintended use of this product shall immediately void all manufacturers warranties. Manufacturer disclaims all

liability for injuries to persons or property resulting from any modification to, or unintended use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

WEATHER GUARD® products are protected by one or more of the following patents or trademarks:

U.S. - 4509787, 842268, 1661625, 1663369, 2228051, 2434963; Canada - 1218968, 282725; U.K. - 1400720; NZ - 296049; Aus.- 761964

KNAACK LLC

420 E. TERRA COTTA AVENUE - CRYSTAL LAKE, ILLINOIS, USA 60014 - 815-459-6020

© 2002 Knaack LLC

4

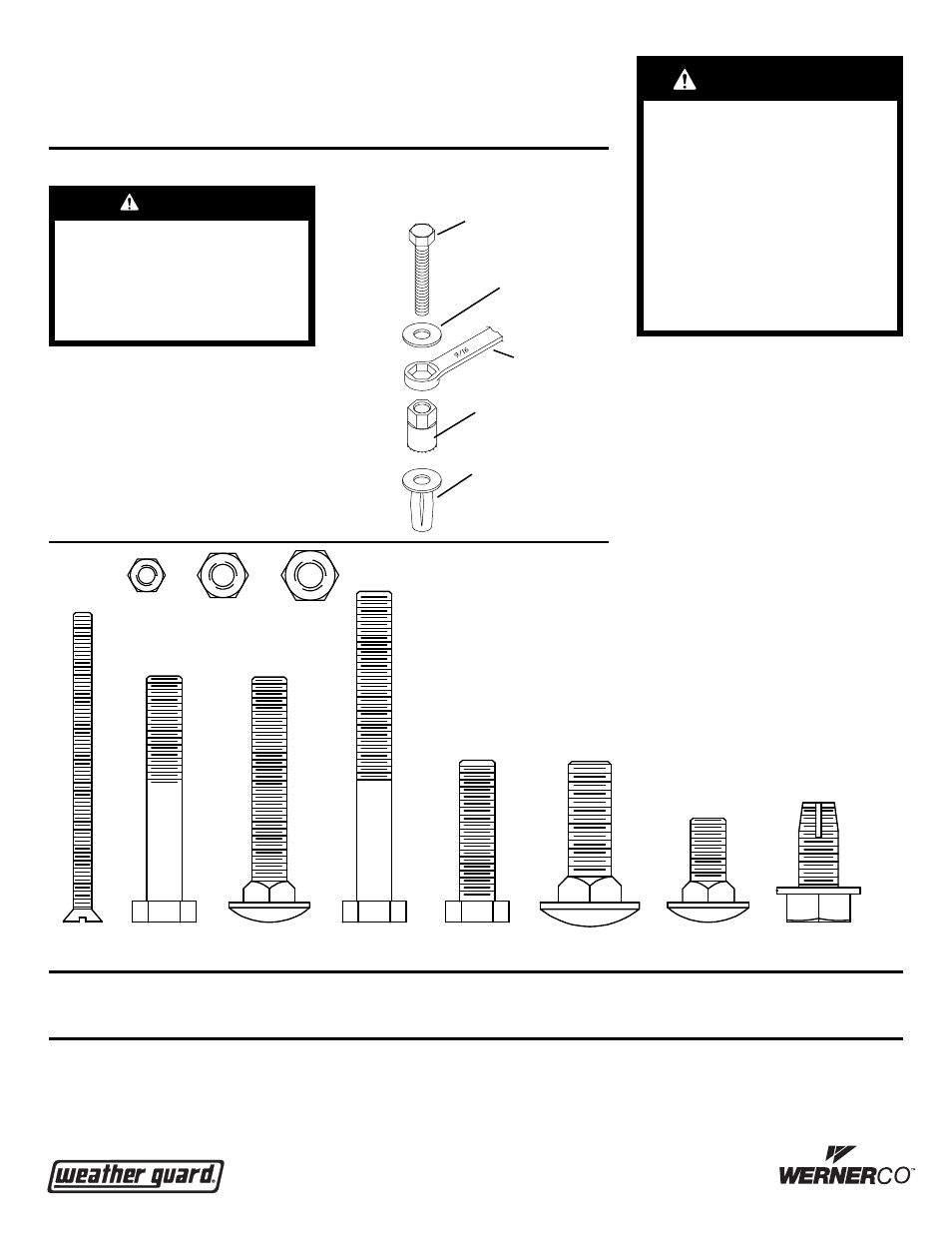

3/8-16 x 1-1/4"

Carriage Bolt

5/16-18 x 2-3/4"

Hex Hd. Bolt

5/16-18 x 2"

Hex Hd. Bolt

5/16-18 x 2"

Carriage Bolt

10-24 x 2-3/4"

F.H. Screw

5/16-18 x 1-1/4"

Hex Hd. Bolt

5/16-18 x 3/4"

Carriage Bolt

3/8-16 x 3/4"

Bolt, Thd. Cut

Nylon Lock Nuts

3/8

5/16

10-24

Bolt Size Chart

WARNING

Ladders must be secured per

ANSI standard A142.2-1990 para-

graph 8.4.4. Ladder damage will

occur from road shock and ve-

hicle vibration if the ladder is not

properly secured to the ladder

rack. Bouncing and side to side

motion of a improperly secured

ladder will cause wear and

weaken the ladder. Using a dam-

aged ladder could lead to a struc-

tural collapse and could result in

a serious injury or death.

WEATHER GUARD® PRODUCT

REFINISHING PROCEDURES

All WEATHER GUARD® products are finished

with a polyester powder coating, and it is im-

portant to follow these procedures to get

proper adhesion. As Knaack LLC cannot

control the finishing of the prod-ucts, the

warranty for WEATHER GUARD®

products on paint is not applicable on refin-

ished products.

1. Sand the surface to be painted with 180-200

grit sand paper to rough up the surface. This

should be followed by wet sanding with a 400

grit wet or dry paper.

2. Wipe down the sanded surface with ketone

based thinner. This removes the dust and soft-

ens the powder coating for better paint adhe-

sion.

3. Wipe sanded area with a tack rag to remove

loose dust and particles before painting.

NOTE: Do not use a lacquer over the

powder coating

INSTALLATION PROCEDURE USING BLIND FASTENERS

WARNING

Prior to drilling, so as not to

cut or puncture fuel tanks,

fuel lines, brake lines, electric

wires, etc., check under vehi-

cle for locations.

Black

Oxide

Bolt

Flat

Washer

9/16

Wrench

Installation

Tool

Blind

Fastener

Place a drop of oil on the black oxide bolt

before assembling as shown on right. Place

the Blind Fastener in the hole and use a

1/2 or 7/16 wrench to tighten black hex

bolt until the blind fastener is fully seated.

When setting black hex bolt, it will start out

hard. As the Blind Fastener bulbs out it

will get easier, until it bottoms out or sets.

Make sure the Blind Fastener and Installa-

tion Tool do not turn during installation.

WARRANTY WILL BE VOID IF

SEALANT IS NOT APPLIED TO

ALL SEAMS AND CREVICES

STEP 12.

Sealant.

Seal all nuts, bolts, and crossmember to

sleeve seam with sealant.

Part No. 24-0132 REV. B ECN 5315 05/13