Warner Electric CB Series and Super CB Series Sizes 2, 4, 5, 6 and 8 User Manual

Page 8

8

Warner Electric • 800-825-9050

P-258 • 819-0406

Troubleshooting Checklist

4. Troubleshooting the Clutch/Brake Unit

When the brake spring is engaged, i.e., fully wrapped down, the input should be free to rotate by hand. Wrapping the

brake spring down completely can be accomplished by rotating the output shaft in the driving direction until it cannot

travel any further. Please note that units with anti-overrun springs (most units) will allow the input hub to turn only in

the direction of rotation.

Possible Problem

Recommended Action

1. Continuous driving (input and output hubs locked

together - unit continues to drive even with collar

blocked)

A. The spring differential setting is too small. Reset differential

(see Section 5 “CB Spring Differential Adjustment”).

B. The endplay (axial clearance between hubs) setting is too

close. Reset the endplay by moving the output sleeve on

the shaft until a minimum of .003" to .006" clearance is

achieved.

CAUTION: Use a brass hammer to avoid shaft

damage.

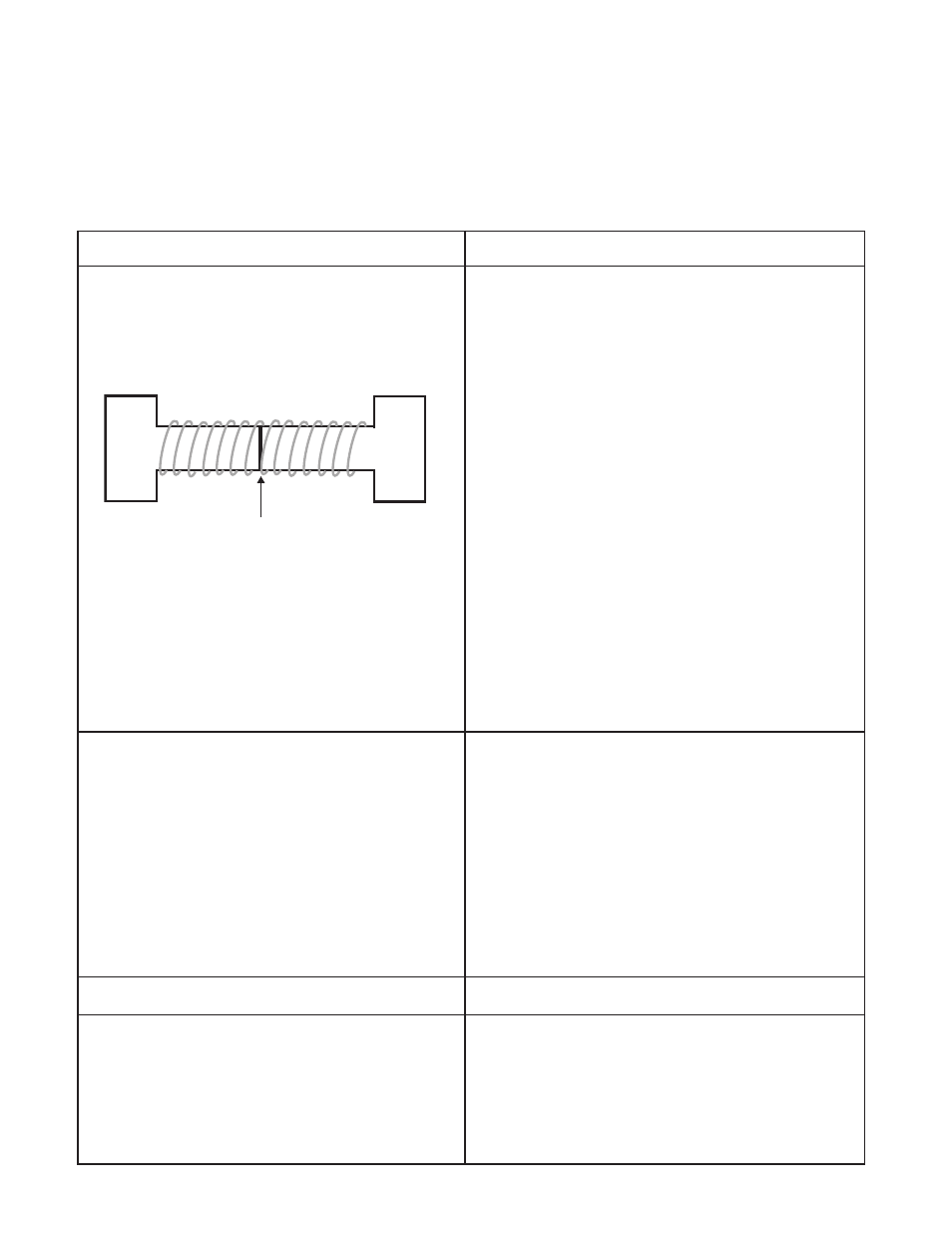

C. The hubs are necked down (worn at the spring crossover

point) and the spring is caught between the two hubs and

cannot release. This could be a result of excess torque

being applied to the unit. Re-evaluate sizing. Replace unit

or rebuild with “Heavy Repair Kit” and then reset endplay.

Note: On Rebuilding Units: As a general rule, when

springs are replaced, the hubs should be as well. Given

that the springs and hubs are the majority of the cost of

the unit, it is often not economically feasible to rebuild units

when replacement of the springs and hubs is required.

D. The bearing surface between the input and output hubs

is galled and the unit should be replaced. If galling was

caused by contaminants, add a dust cover to reduce

contamination (See Section 6). If galling was caused by

excessive radial side loading or an overhung load, correct

this condition by mounting the input member properly

(See Section 2).

2. Input is free, but the clutch won’t engage when actuated.

A. The spring differential setting is too loose. Reset the

differential (see Section 5 “CB Spring Differential

Adjustment”).

B. Check the clutch spring for damage. Replace as necessary

with “Light Repair Kit.”

C. The control collar cannot move because foreign matter is

blocking it. Clean the unit and add a dust cover to reduce

contamination (See Section 6).

D. The actuator/cam tip clearance is inadequate. Reset the

airgap by realigning the coil (See Section 3, Step 3A).

E. The coil has failed. Replace coil and realign to set airgap.

(See Section 3, Step 3A).

3. Clutch/Brake stalls motor when engaged.

A. See solutions to Problem 1, “Continuous driving.”

4. Control collar tang slot ripped out.

A. The spring differential setting was incorrect or altered.

Replace the collar and reset the spring differential (See

Section 5).

B. Unit was rotated in reverse direction. Replace broken parts

with “Light Repair Kit.”

Do not reverse unit.

C. The torque or inertia of the application is too large for the

unit. Re-evaluate unit size.

Input

Output

Hub

Hub

Crossover point is

where the spring crosses

over from one hub to

the other.

Figure 6