Horizontal mounting – Warner Electric CB Series and Super CB Series Sizes 2, 4, 5, 6 and 8 User Manual

Page 4

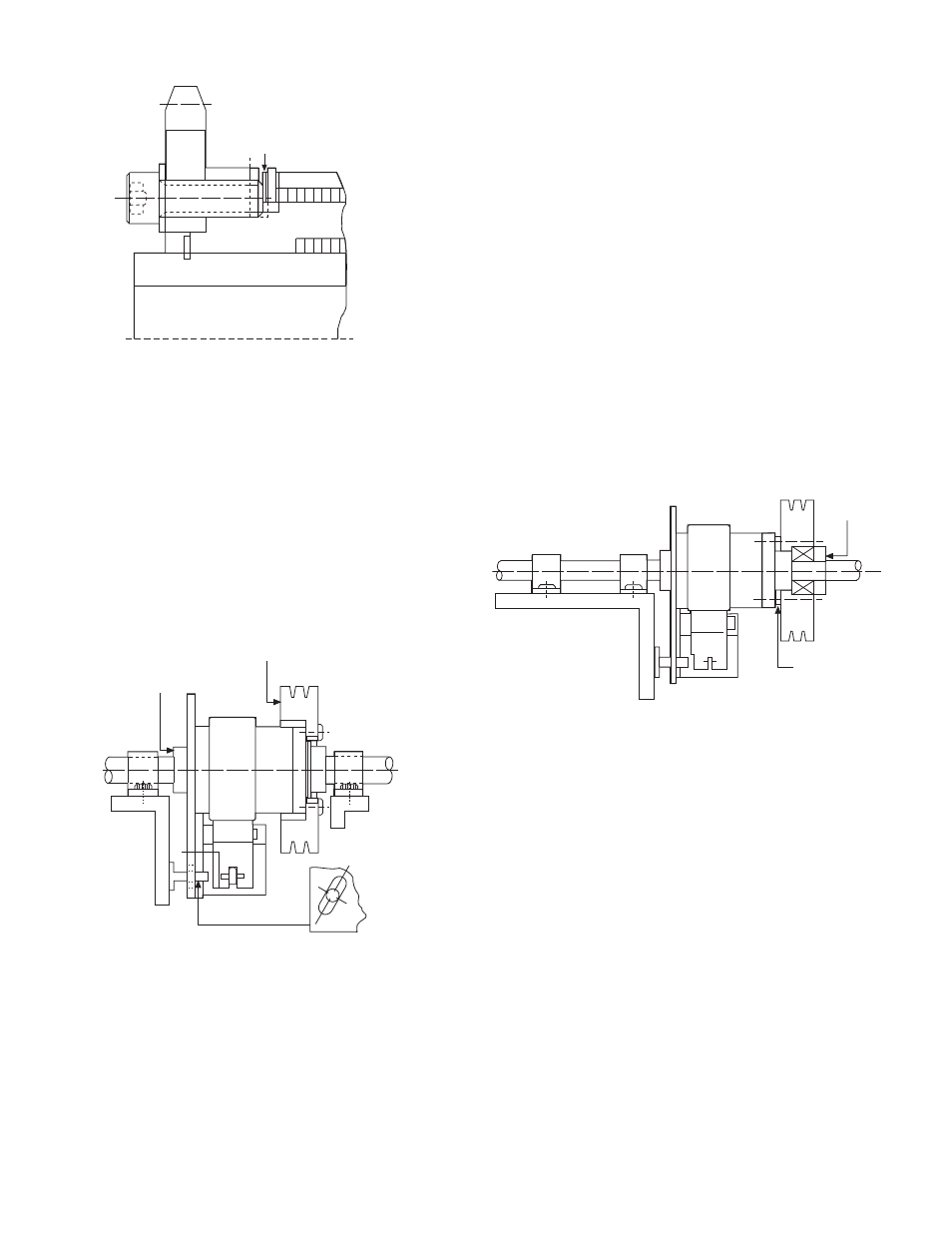

Figure 2 – Acceptable Mounting

If the application contains a substantial radial

bearing load, arrange the pulley over the

centerline of the clutch free hub as illustrated

in Figure 3. Place one support bearing as

close to the pulley as possible, using a torque

arm for anti-rotation.

Customer's Bearing-

Mounted Pulley

Double Bearing Support

for Stub Shaft

Set Collar

Pin Drive

Not Bolted

to Input

Secure Pulley

to Hub

4

Warner Electric • 800-825-9050

P-258 • 819-0406

Horizontal Mounting

Figure 1 illustrates an ideal clutch/brake mounting

application. The unit is attached to the output

shaft with both a key and set screws. The plate

is restrained from rotating, but not from axial

movement, reducing the side load on the CB’s

internal plate bearing.

Figure 1 - Ideal Mounting

Clutch fully supported by

the shaft with bearing

support on both ends

Customer's Input member

counterbored to center mass

over clutch bearing

Plate restrained from rotating by pin

or shoulder bolt. No axial binding

+

Thread engagement

exceeds factory specifications.

This causes interference

which results in clutch

malfunction.

Incorrect Thread Engagement

In cases where easy access to the input is

desirable, the clutch/brake can be mounted

on a stub shaft. However, the unit must still

be fully supported, while overhung loads on

the input member must be avoided to

maintain the life of the radial bearing.

Figures 2 and 3 illustrate alternate mounting

configurations for achieving proper support.

Inputs are usually face-mounted to the input

hub of the CB unit as shown in Figure 1. This

type of mounting is facilitated by the drilled

and tapped holes provided in the free hub

flange. The configuration shown in Figure 2

is a possibility, if the radial load on the input

hub of the CB is small compared to the

specified load.