Warner Electric 1300-76 12 Volt Utility Controller for 4, 6, or 8 User Manual

Page 5

Warner Electric • 800-825-9050

P-1396 • 819-0301

5

4. Remove a knock-out plug or cut a hole in the

firewall near the mounted controller.

5. Cut the wire to a proper length for reaching

the controller. Strip the wire and feed it

through the firewall hole.

6. Connect this wire to the blue brake lead wire

extending from the back of the controller.

Note: Solder or crimp clamp connections

will be required when connecting all three

controller lead wires. Wrap electrician’s

tape around all bare wire joints. Do NOT

use twist-type connectors.

7. Making a chassis ground connection is the

next installation step. Strip one end of the

remaining length of hook-up wire and connect

it securely to the ground terminal of the

socket at the rear of the towing vehicle.

8. Feed the wire under the towing vehicle to a

convenient chassis ground, such as a body

or chassis nut and bolt, battery ground-post,

etc. Cut and strip the wire and attach it

securely to this ground. A good ground

connection is essential for proper

operation.

9. Two Utility Controllers leads are still to be

connected. The red lead actuates the

stoplights when the controller is operated

manually. An interrupted stoplight circuit for

turn signals is used on most towing vehicles.

Connect the controller’s red lead to the output

side of the towing vehicle stoplight switch.

(This switch could be a pressure switch

located in the brake line or a limit switch

activated by the brake pedal.) Connect an

inline fuse in series between the red lead and

the stoplight switch. This fuse should be the

same type and rating as recommended for

the tow vehicle’s existing stoplight circuit.

Splice a short length of hook-up wire to the

red lead to reach the stoplight switch output.

If your towing vehicle has some other system,

consult your automotive dealer.

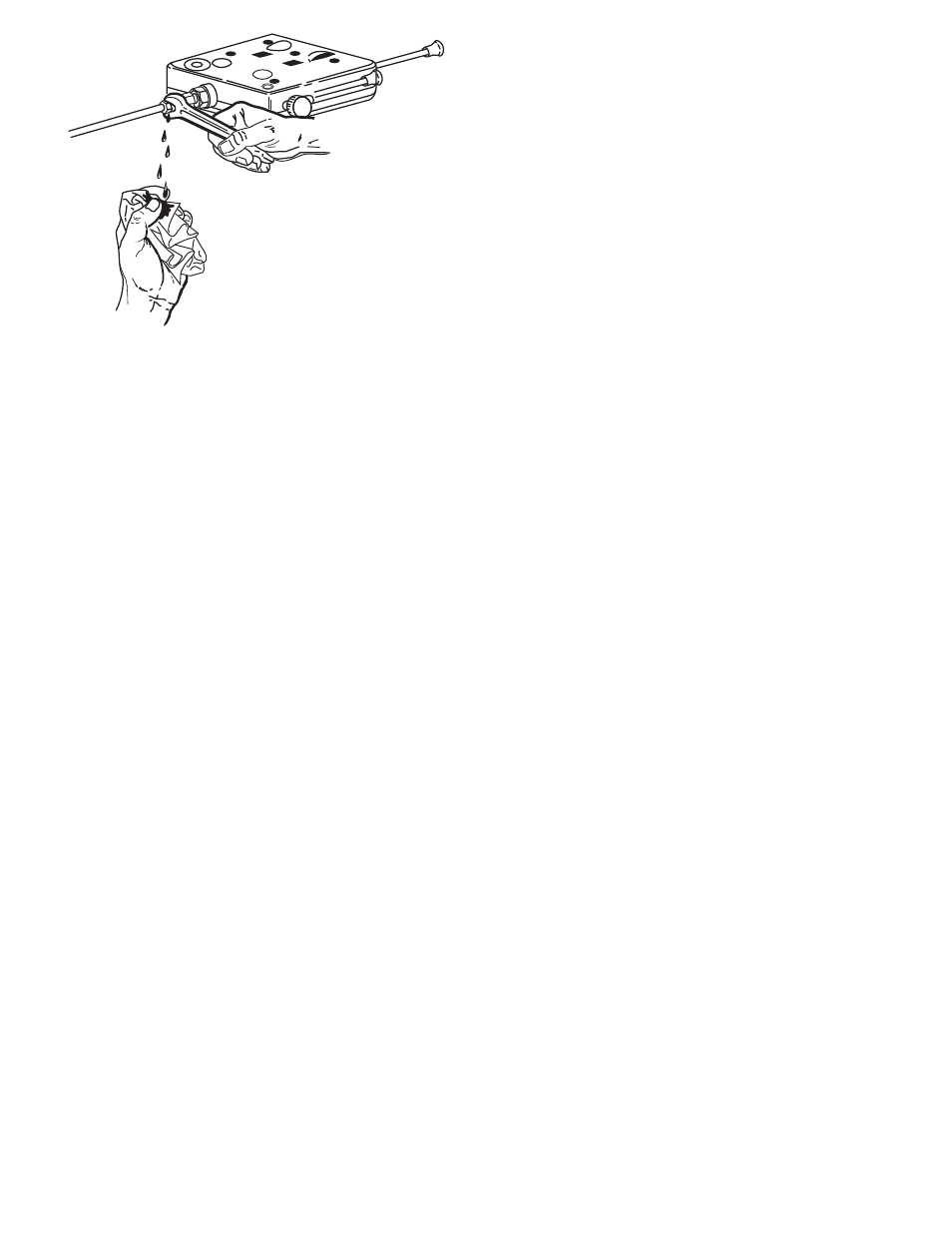

Figure 6

9. To test for sponginess and leaks, pump the

brake pedal and hold it depressed for

approximately one minute. If sponginess

exists, the entire system should be bled at

the wheel cylinders. Refill the master cylinder

fluid reservoir as required.

Electrical Connection

1. Electrical connection is required for all

installations. Approximately 25 ft. of

automotive-type multistranded 12 gauge or

heavier single wire with tough, thermoplastic

insulation meeting SAE standard J558a is

required.

Note: When towing a trailer which will carry

variable loads, or which is light weight when

compared with its brake capacity, a Warner

Electric Load Control part No. 1300-78, may

be required to properly proportion braking

force between the trailer and the towing

vehicle. See Optional Equipment.

2. An electrical socket which mates with the

trailer power cable is to be installed in the

rear of the towing vehicle. Strip one end of

the hook-up wire and connect it to the brake

terminal of this socket.

3. Secure a single length of wire from the brake

connection of the socket to the underside of

the towing vehicle and lead it to the engine

firewall. Position the wire to insure maximum

protection from scraping on the road surface

in rough terrain, flying stones, spray, etc. Also

avoid attaching wires near mufflers and

exhaust pipes. Wires should be clamped at

frequent intervals.