Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 6

6

Warner Electric • 800-825-9050

P-1401 • 819-0316

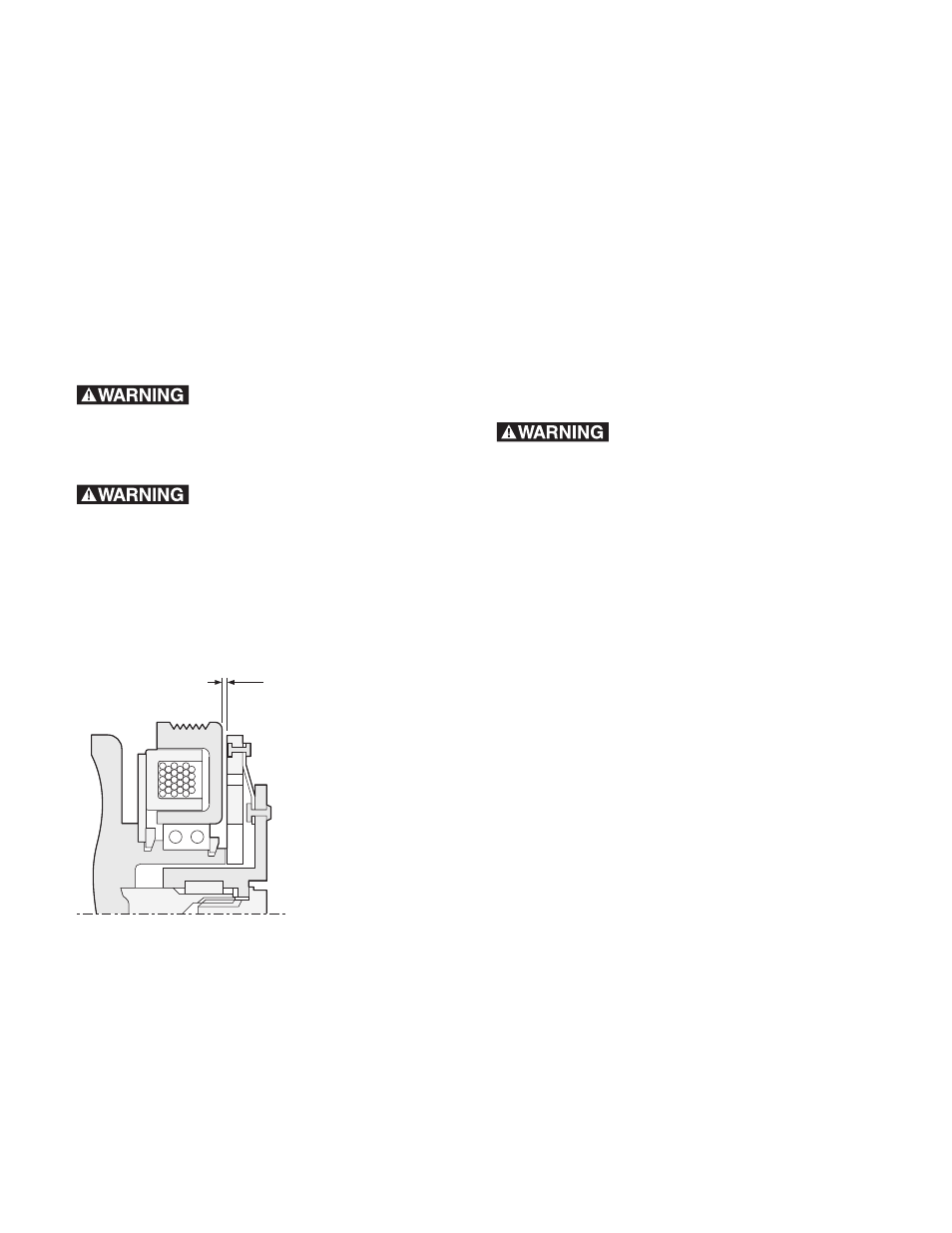

0.020

(0.51)

0.040

(1.02)

Rotor/Pulley to

Hub/Armature Airgap

(Measured 3 places

120° apart)

to

Figure 7

Step 4: Installing the Hub/Armature

Assembly (9)

A. Align the hub keyway with shaft key (7) and

slide the hub/armature (9) onto the compressor

shaft.

B. Set the rotor/pulley to hub/armature air gap at

0.020 to 0.040 inches by adding or removing

shims (8). Measure using a feeler gauge at 3

locations 120° apart. (See Figure 7)

C. Install the lockwasher (10) and shaft nut (11).

Torque to 155 lb.in. using a torque wrench and

spanner wrench.

Use a hub/armature removal

tool (reference Chrysler tool C-4561 or

equivalent) to install and remove the

hub/armature (9).

Do not use screwdrivers

between the hub/armature and rotor/pulley

to remove hub/armature as clutch will be

damaged.

Note: The shims (8) may compress when the

shaft nut (11) is tightened; therefore, recheck

the airgap at three locations 120° apart.

Step 5: Clutch Assembly Check

A. Rotate the clutch and check for rubbing or

interference.

B. Reinstall belts per manufacturer's service

manual. Do not over tighten.

C. Recheck the airgap at 3 or 4 points and

check for clutch rubbing.

D. Important: Burnish as follows. Run the

clutch at 2500 to 3000 RPM. Cycle the clutch

ON and OFF at a rate of 10 to 15 times per

minute maximum for a total of 50 cycles

minimum. This should bring the clutch up

to operating torque capacity.

Cycle the clutch using the

controls inside the car or electrical system

damage could result.