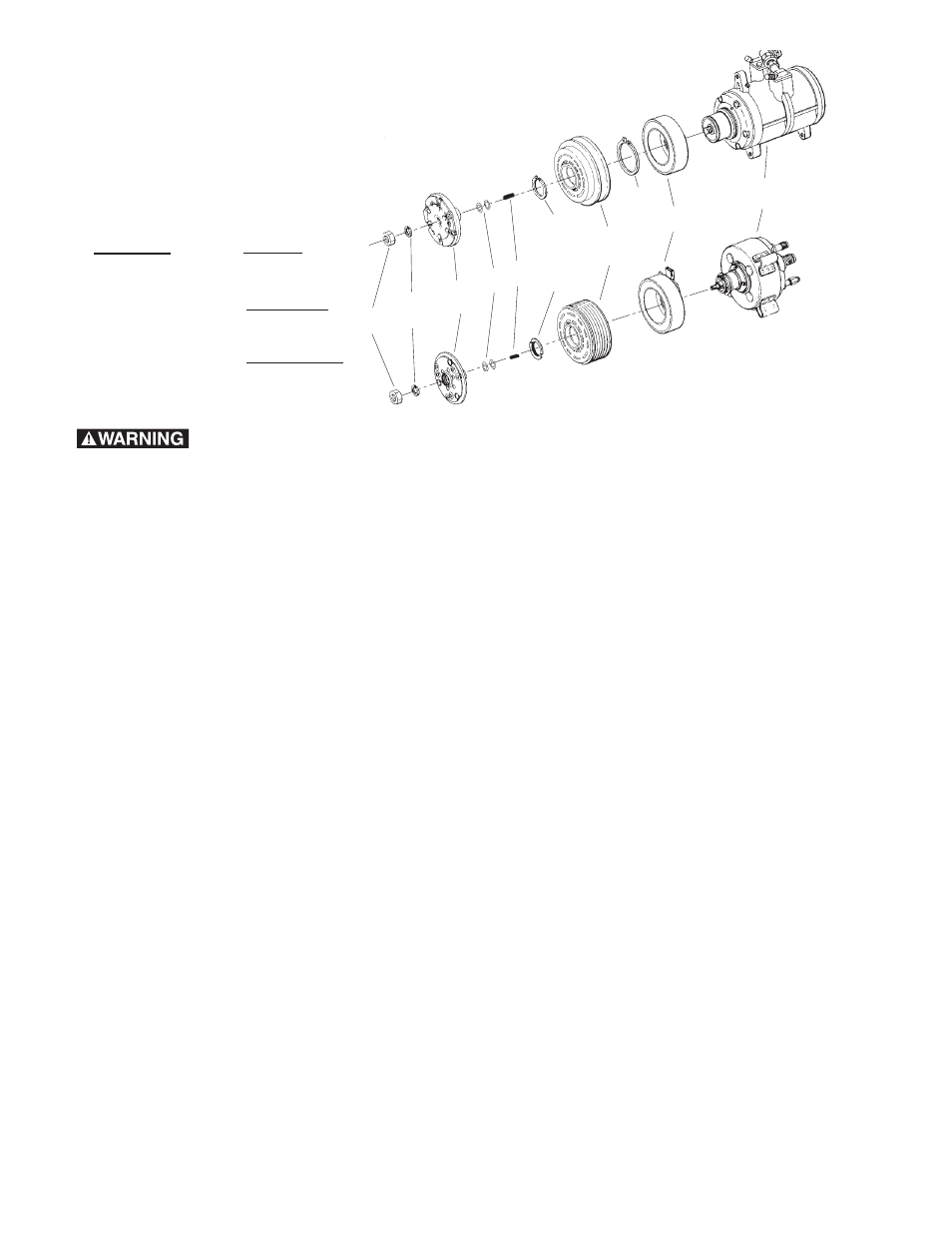

Step 1: diagnose clutch failure, Step 2: removal of hub/armature assembly (9), Ford – Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 2: Chrysler, Tecumseh, Fs-6, C-171, Hr980

2

Warner Electric • 800-825-9050

P-1401 • 819-0316

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Note: During compressor clutch removal DO

NOT pound on the clutch or compressor as

damage will result.

Step 1: Diagnose Clutch Failure

Most compressor clutch failures are a direct

result of an A/C system problem or failure.

Before installing a new clutch, determine what

caused the old clutch to fail and fix the system

problem. By simply re placing the clutch without

fixing the cause of the clutch failure, the new

clutch may fail in the same manner as the old

clutch. Please refer to the Warner Electric "Air

Conditioning Clutch Trouble Shooting Guide"

and the appropriate manufacturer's A/C

Service Manuals.

Step 2: Removal of Hub/Armature Assembly

(9)

Special tools must be used to avoid damaging

the compressor.

A. Remove shaft nut (11) with a 13mm socket

wrench and spanner wrench.

B. Remove lock washer (10).

C. Remove hub/armature (9) with a hub/armature

removal tool (reference Chrysler Tool # C-4561

or equivalent).

D. Remove shims (8) from the hub/armature and

shaft.

Step 3A: Removal of Rotor/Pulley Assembly

(4) (All compressors except HR980)

A. Remove rotor/pulley snap ring (5).

B. Slide rotor/pulley assembly (4) off the

compressor (1) nose. If rotor/pulley assembly

is hot and will not slide, DO NOT FORCE! Allow

the clutch to cool and then proceed.

C. Proceed to Step 4.

Warner Replacement Clutches

for the following compressors:

Denso

6E171

10P15

6P148

6C17

Ford

FS-6

Chrysler

C-171

Tecumseh

HR980

11

Shaft Nut

10

Lock

Washer

8

Shims

7

Key

6

Rotor/Pulley

Retainer nut

4

Rotor/Pulley

Assembly

2

Field Coil

1

Compressor

9

Hub/Armature

Assembly

5

Rotor/Pulley

Snap Ring

3

Field Coil

Snap Ring

HR980

FS6, C171, A590,

6E171, 10P15,

6P148, 6717