Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 3

3

Warner Electric • 800-825-9050

P-1401 • 819-0316

Step 3B: Removal of Rotor/Pulley

Assembly (4) and Field Coil Assembly (2)

(HR980 Compressor only)

A. Disconnect the electrical connection on the

field coil (2).

B. Unscrew the rotor/pulley retainer nut (6) with a

spanner wrench.

C. Slide the rotor/pulley assembly (4) off the

compressor (1) nose. If rotor/pulley assembly

is hot and will not slide, DO NOT FORCE!

Allow the clutch to cool and then proceed.

D. Remove field coil assembly (2).

Step 4: Removal of Field Coil Assembly (2)

(All compressors except HR980)

A. Separate electrical connection and, if

applicable, remove clutch wire retaining clip

from the compressor.

B. Remove field coil snap ring (3) retaining the

field coil.

C. Remove the ground screw on the compressor,

if used.

D. Slide the field coil (2) off the compressor

housing.

Installing Clutch on Compressor

Replace the complete clutch to ensure required

performance is achieved and warranty

requirements are met.

Step 1: Preparation of Compressor

A. Clean compressor nose of all dirt, grease

or debris. Check for evidence of oil leakage

from the front seal and through bolts of the

compressor. Repair or replace compressor

as appropriate.

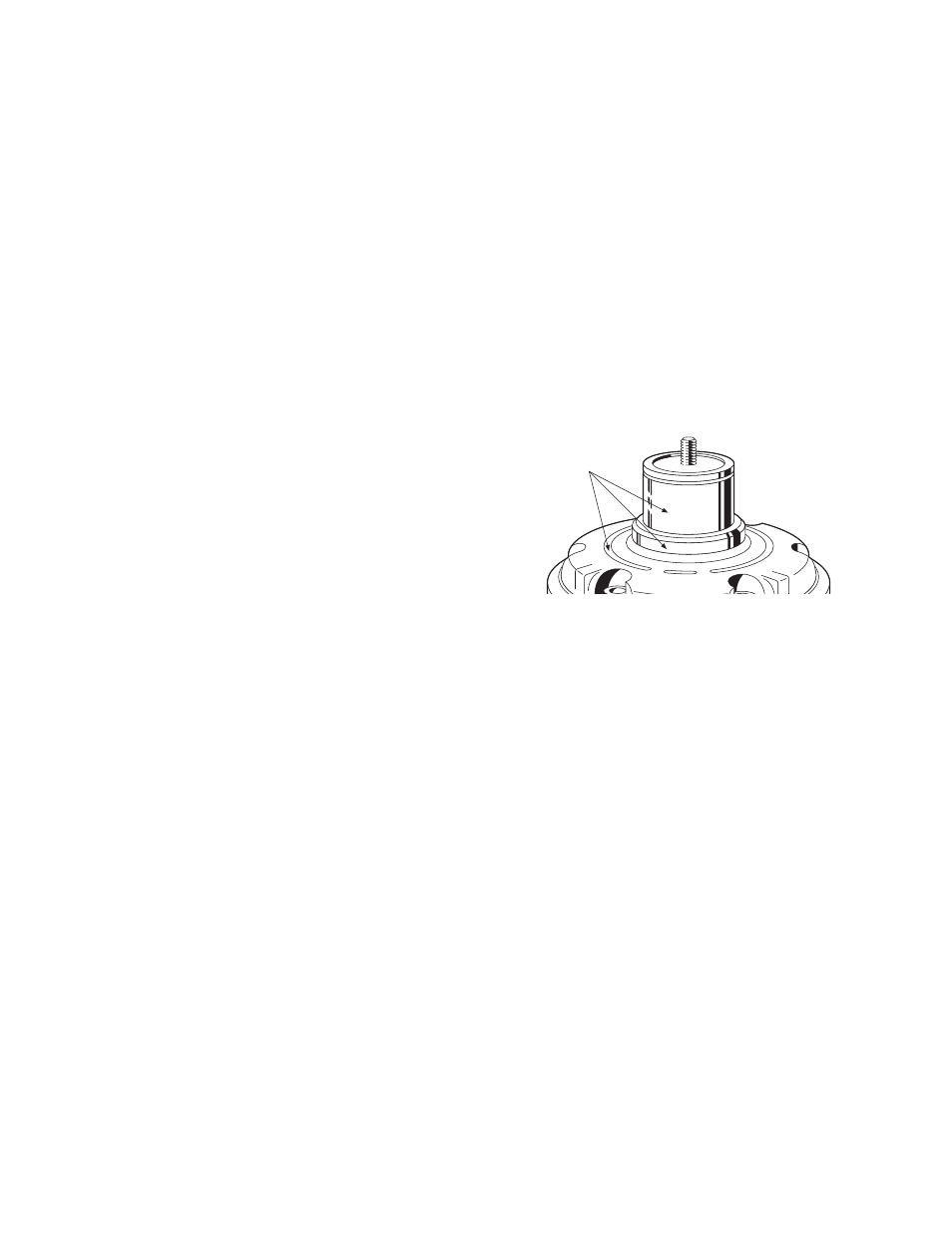

B. Check mounting surfaces for nicks, burrs and

scratches (See Figure 1). Smooth with a file

or emery cloth, if necessary.

C. Make an electrical system check with all

electrical accessories turned on to ensure

that the voltage available to the clutch is

10.8 volts minimum.

Mounting

Surfaces

Figure 1