Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 5

5

Warner Electric • 800-825-9050

P-1401 • 819-0316

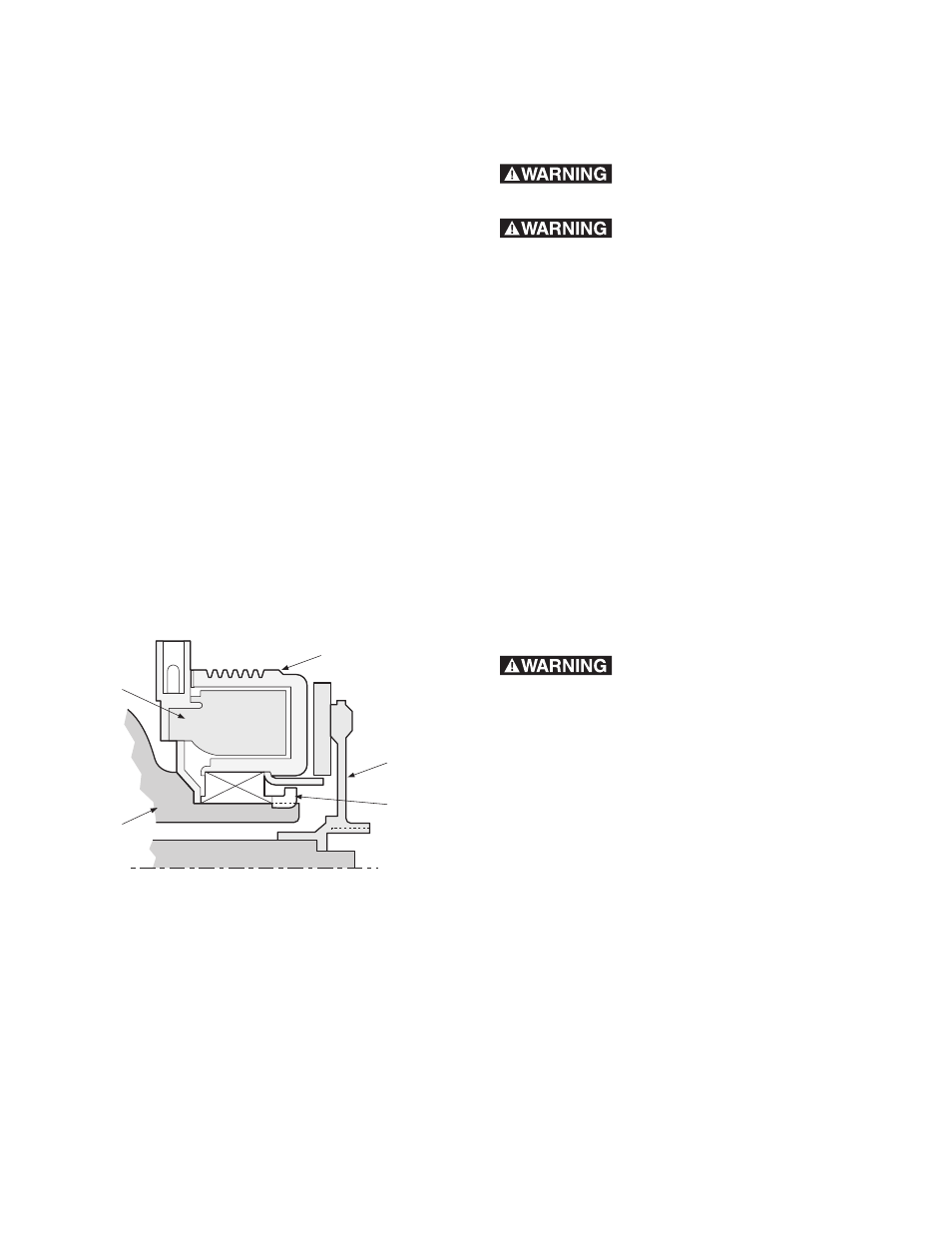

Rotor/Pulley

Retaining Nut

Hub/Armature

Assembly

Rotor/Pulley

Assembly

Field Coil

Assembly

Compressor

HR980

Figure 6

Step 3: Installing the Rotor/Pulley

Assembly (4) (All Compressors except

HR980)

Do not mar the rotor/pulley

and hub/armature friction surfaces.

Prevent any oil or grease from

contaminating the friction surfaces.

A. Install the rotor/pulley assembly (4) onto the

compressor (1). If the rotor/pulley does not

slide on easily check the compressor nose for

nicks or burrs and remove. If the rotor/pulley

still does not slide on easily, rock the

rotor/pulley back and forth by hand until it

slides completely onto the compressor (1).

B. Make sure there is no interference between

the field coil (2) or lead wires and the rotating

rotor/pulley (4).

C. Install the rotor/pulley snap ring (5). With a

snap ring pliers, spread the snap ring and

insert it into the groove on the compressor

nose. (See Figure 2) To assure assembly

retention, the snap ring bevel must face away

from the compressor. (See Figures 3 and 4)

The snap ring pliers must not

contact the bearing seal or a seal failure may

result.

D. Verify that the snap ring (5) is fully seated

in the groove around its circumference to

assure assembly retention. (See Figure 4)

Step 2B: Installing the Field Coil (2)

and Rotor/Pulley Assembly (4) (HR980

Compressor only)

A. Align square holes in the back plate of the

coil assembly (2) with lugs on the compressor

(1) housing.

B. With the field coil (2) in position, slide the

rotor/pulley (4) onto the compressor until it

butts against the field coil (2). (See Figure 6)

If the the rotor/pulley does not slide on easily,

check the mounting surface on the

compressor nose for nicks or burrs and

remove them. If the rotor/pulley still does not

slide on easily, rock the rotor/pulley back and

forth by hand until it slides completely onto

the compressor.

C. Install the rotor/pulley retainer nut (6) with

flange notches facing AWAY from the

rotor/pulley assembly. Tighten the retainer nut

to 65 to 75 lb.ft. torque.

D. Make electrical connection.

E. Proceed to Step 4.