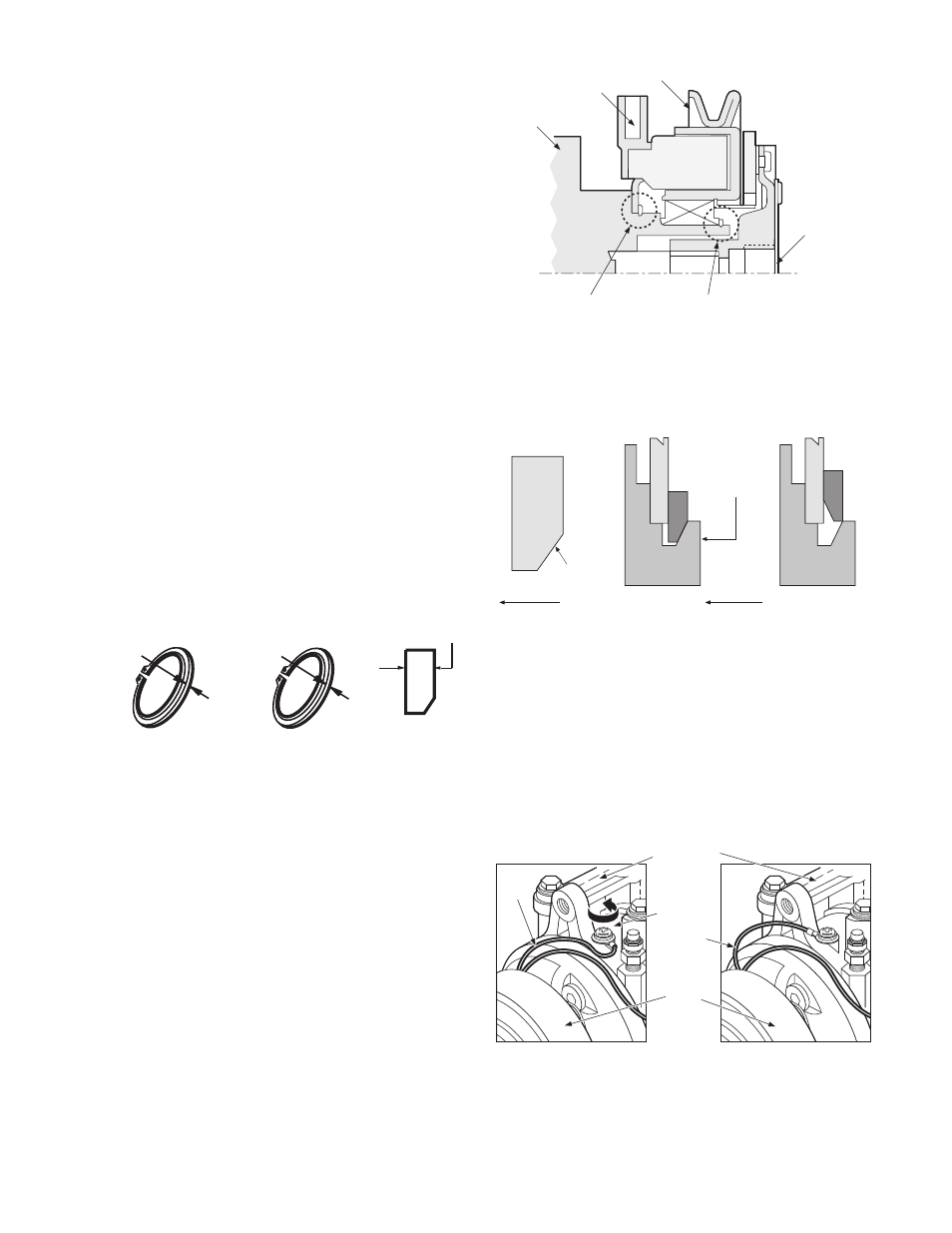

Use the correct retaining ring (3), Location of clutch snap rings, Figure 2 – Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 4

4

Warner Electric • 800-825-9050

P-1401 • 819-0316

Step 2A: Installing the Field Coil (2)

(All Compressors except HR980)

Note: Failure to install snap rings per these

instructions can be verified and will void the

compressor clutch warranty.

A. Align the hole in the back plate of the field

coil (2) with the anti-rotation pin in the

compressor end housing. Place the field

coil into position. Make sure that the lead

wires are routed directly to the retaining

clip on top of the compressor.

B. Install field coil snap ring (3).

Use the Correct Retaining Ring (3)

During the 1981 model year, the retaining

ring used to hold the Chrysler C171 field coil

assembly (2) in place was made thicker. Check

the thickness of the old ring which was removed

and verify that the new ring is the same

thickness (*except 6C17 Compressor). The field

coil assembly must be tight on the compressor.

*For a 6C17 Compressor, Install the field coil

assembly (2) with the retaining ring (3) provided

with the new Warner clutch. Discard the old

retaining ring.

With a snap ring pliers, spread the field coil

snap ring (3) and insert it into the groove on the

compressor nose. (See Figure 2) To assure

assembly retention, ring bevel must face away

from the compressor. (See Figures 3 and 4)

Verify that the snap ring is fully seated in the

groove around its circumference to assure

assembly retention. (See Figure 4)

Attach the ground lead, if used, to the

compressor housing and tighten the screw

to 17 lb.in. torque. (See Figure 5)

Rotor/Pulley

Assembly

Hub/Armature

Assembly

Field Coil

Assembly

Field Coil Assembly

Snap Ring

Compressor

Rotor/Pulley Assembly

Snap Ring

Figure 2

Location of Clutch Snap Rings

Fully seated

snap ring

Bevel

Compressor

Install with beveled face away from compressor

Snap Rings

Compressor

Correct

Incorrect

Figure 3

Snap Ring

Bevel

Figure 4

Correct and Incorrect Installation

Note: When attaching the clutch ground wire to

the compressor, rotate the ring terminal

COUNTERCLOCKWISE to remove slack in

the wire. Failing to remove slack may result

in the pulley rubbing on the ground wire on

some models.

Right

Wrong

Figure 5

Clutch

Field

Coil

Assembly

Compressor

Rotate

Remove

Slack

Taut

Wire

PRE-1981

0.058 to 0.065

Inches Thick

POST-1981

0.075 to 0.081

Inches Thick

Thickness

Measurement