Installation, Caution, For mounting on a stud wall – Staub Electronics SM-RAZOR-M STRONG - MEDIUM FIXED ZERO CLEARANCE MOUNT FOR 23-46 User Manual

Page 2: For mounting on a concrete wall, Correct, Incorrect, Warnings, Specifications, Box contents, Tools required

Correct

concrete

concrete

plaster/

drywall

plaster/

drywall

Incorrect

Cuta

w

ay

Vie

w

Figure 3

Drill holes and

insert anchors.

Place wall arm

assembly plate

over anchor and

secure with

lag screw.

Tighten all

lag screws.

Wall Arm

Concrete

Wall

Flange Bolt

Figure 4

NS

WARNINGS:

• Installation by a qualified professional is highly recommended for this product.

• Do not begin installation until you have thoroughly read and understand these instructions.

• Medium mount supports displays from 32-46”, VESA 200X200; 300X300 up to 400X300, and a maximum load of 125 lbs.

Large mount supports displays from 37-63”, VESA 200X200; 300X300 up to 800X500, and a maximum load of 125 lbs.

• Ensure the mounting wall will safely support four times the combined weight of the Mount

and display panel.

• Under no circumstances should this product be mounted to metal studs.

• The manufacturer does not accept responsibility for incorrect installation.

• Due to low profile, check with the TV manufacturer to ensure the particular display being used

can be installed 5mm from the wall.

SPECIFICATIONS:

• Maximum Load: 125 lbs. (56 kg)

• Display Size

Medium: 32-46”

Large: 37-63”

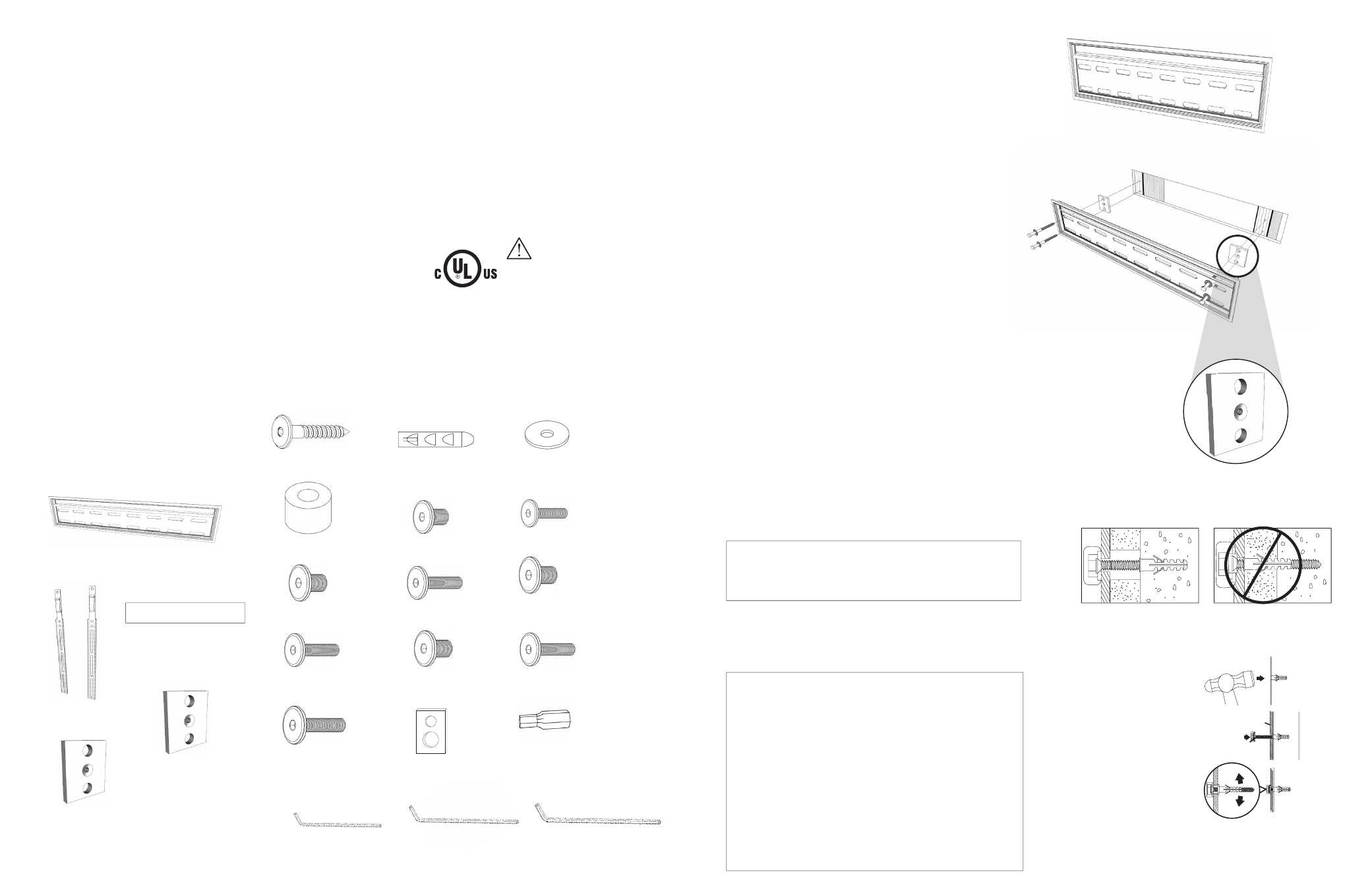

BOX CONTENTS:

• Wall Plate (1)

• Arm left (1)

• Arm right (1)

TOOLS REQUIRED:

• Power Drill

• 5/16” and 3/16” Drill Bit

• Phillips Head Screw Driver

• Level

• Drywall Saw

• Stud Finder

PACKAGE CONTENTS:

Wall Plate

Arms

Clear Plastic

Adhesive Sheet (x1)

HARDWARE KIT

Figure 1

(A)1/4” Backplate Spacer (x2)

(P) 25mm×25mm Diameter Washer(x4)

(B) 1/8” Backplate Spacer (x2)

(C) M6x50mm Lag Screws (x4)

(D) Concrete Anchors (x4)

(E) Washers (x4)

(F) 1/4” ABS Spacer (x4)

(G) M4X12 (x4)

(H) M4X25 (x4)

(J) M5X25 (x4)

(L) M6X25 (x4)

(N) M8X25 (x4)

(O) M8X30 (x4)

(K) M6X12 (x4)

(M) M8X12 (x4)

(Q) Allen Key Drill Bit (x1)

(I) M5X12 (x4)

(R) M2.5X55mm Allen Key

(S) M4X100mm Allen Key

(T) M5X100mm Allen Key

TIP: If needed,

use a Backplate

Spacer suited for your

drywall thickness when

mounting in the wall

(1/8” for 5/8” drywall,

1/4” for 3/4” drywall).

Figure 2

CAUTION:

These wall mounts are

intended for use only with

the maximum weight of :

SM-RAZOR-M: 125 lbs (56kg)

SM-RAZOR-L: 125 lbs (56kg)

INSTALLATION:

Note: The SM-RAZOR-M/L mount is designed for in-wall instal-

lations when applicable.

Step 1: Mounting the Wall Bracket Assembly

For Mounting into a Stud Wall

a. Use a stud finder to locate stud positioning for optimal

placement. A minimum of two studs are needed.

b. Using the Wall Plate, place against the wall face out

and trace around the outside of the recess. Remove

the Wall Plate and use a dry wall saw to cut and

remove the drywall, leaving studs in place.

c. First verify fit of Wall Plate into hole without attaching

(flanges should cover cuts), then remove.

d. Optional next step: Remove backing of Clear

Plastic Adhesive Sheet (included) and place over

backside of Wall Plate to cover up exposed holes to

help eliminate draft from in-wall once mount is installed.

e. Pre-drill holes into two wood studs using a 3/16” drill bit.

Be sure to drill into the center of the studs at least

2 ½” deep.

f. If drywall is greater than ½”, determine Spacer

needed (either 1/8” or1/4”) to help set depth of Wall

Plate flush with drywall. Using a drywall screw, install

Spacer (A or B) to stud first through center, tapered hole.

g. Insert four Lag Screws (C) into holes through the Wall

Plate and tighten down with Allen Key (S).

For Mounting on a Stud Wall

a. Pre-drill holes into two wood studs using a 3/16” drill bit.

Be sure to drill into the center of the studs at least

2-1/2” deep. The use of a stud finder is highly

recommended.

b. Insert four Lag screws (C) into holes through the Wall

Plate and tighten down with Allen Key (S).

WARNING:

Tighten bolts so that wall plate is firmly

attached, but do not overtighten. Overtightening

can damage the bolts, greatly reducing their

holding strength.

For Mounting on a Concrete Wall

a. Pre-drill holes into concrete using 5/16” drill bits to a

depth of 2 1/2”. Insert concrete Wall Anchors (D)

and tap in-with hammer, if necessary (Figures 3 & 4).

WARNING:

When installing wall arm assembly on

cinder block, verify first that you have a minimum

of 1-3/8” of concrete thickness to be used for the

concrete anchors. Do not drill into mortar joints! Be

sure to mount in a solid part of the block, generally

1”minimum from the side of the block. Cinder block

must meet ASTM C-90 specifications. It is suggested that

a standard electric drill on slow setting is used to drill the

hole instead of a hammer drill to avoid breaking out the

back of the hole when entering a void or cavity.

Concrete must be 2000 psi density minimum.

Lighter density concrete may not hold anchors

.

Make sure that the supporting surface will safely

support the combined load of the equipment and

all attached hardware and components.