Staub Electronics SM-FLAT-S STRONG - SMALL LOW PROFILE FLAT MOUNT FOR 13-26 DISPLAYS User Manual

Page 2

WARNINGS

• We highly recommend this product be installed by a qualified professional.

• Please do not begin installation until you have thoroughly read and

understood these instructions.

• This mount supports display mounting from 13” to 26”, VESA 75X75,

100x100 & 200x100 and supports a maximum load of 40 lbs (18.2 kg).

• Ensure the wall that you plan to use will safely support four times the

combined weight of the mount and your chosen display.

• Under no circumstances should this product be mounted to metal studs.

• The manufacturer does not accept responsibility for incorrect installation.

SPECIFICATIONS

• Maximum Load: 40 lbs. (18.2 kg)

• Display Size: 13” to 26”

• Profile: ¾”

BOX CONTENTS

• Wall Arm Assembly (1)

• Adapter Plate (1)

• Hardware kit (1)

INSTALLATION INSTRUCTIONS

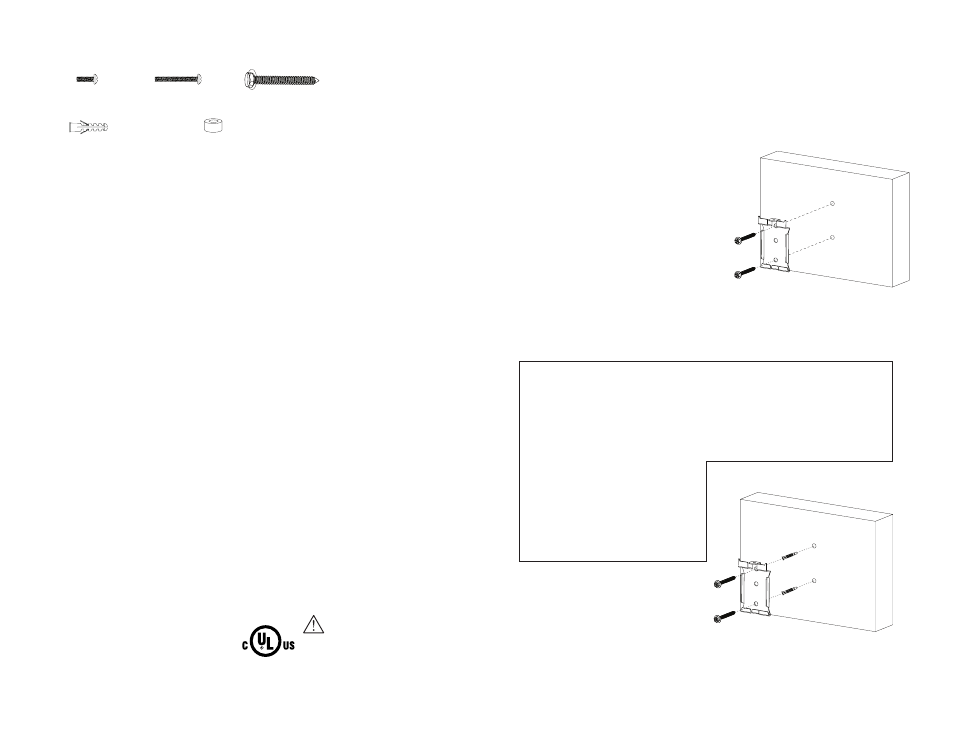

Step 1: Use Wall Plate to Mark Mounting Hole Locations

a. The use of a stud finder is highly recommended.

Step 2: Mount the Wall Arm Assembly

For Mounting on a Stud Wall (Fig 1)

a. Pre-drill two holes into stud using a 3/16” drill bit.

Be sure to drill into the center of the studs.

b. Insert two Lag Screws into holes through

the Wall Plate and tighten down. Be sure

the Wall Plate is mounted with the mounting

tabs pointing upwards.

WARNING: Tighten screws so that the

Wall Plate is firmly attached, but

do not over tighten. Over tightening

can damage the screws, greatly

reducing their holding strength.

For Mounting on a Concrete Wall (Fig 2)

a. Pre-drill two holes into concrete using 5/16” drill bits. Insert Concrete Wall

Anchors and tap in with hammer, if necessary.

WARNING: When installing Wall Arm Assembly on cinder block, verify first that

you have a minimum of 1-3/8” of concrete thickness to be used for the

Concrete Wall Anchors. Do not drill into mortar joints! Be sure to mount in

a solid part of the block, generally 1”minimum from the side of the block.

Cinder block must meet ASTM C-90 specifications. It is suggested that a

standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering

a void or cavity.

Concrete must be 2000 psi density

minimum. Lighter density concrete

may not hold concrete anchor.

Make sure that the supporting surface

will safely support the combined load

of the equipment and all attached

hardware and components.

b. Insert two Lag Screws into the

Wall Anchors through the Wall

Plate. Be sure the Wall Plate is

mounted with the mounting

tabs pointing upwards.

WARNING: Tighten screws so that wall plate

is firmly attached, but do not over tighten.

Over tightening can damage the screws,

greatly reducing their holding strength.

HARDWARE KIT

M4 x 12mm Philips

Head Screw (x4)

M4/M5/M6 spacer:

12mm (x4)

Concrete Wall Anchor (x2)

M4 x 25mm Philips

Head Screw (x4)

TOOLS REQUIRED

• Power Drill

• 3/16” (5mm) Drill Bit

• 5/16” (8mm) Masonry Bit

• Phillips Head Screw Driver

• Level

Fig 2

Fig 1

#14 x 2.5” Lag Screw (x2)

CAUTION:

This wall mount is intended

for use only with the maximum

weight of 40 lbs (18.2kg).