KB Electronics KBMM-225D User Manual

Page 18

6.9

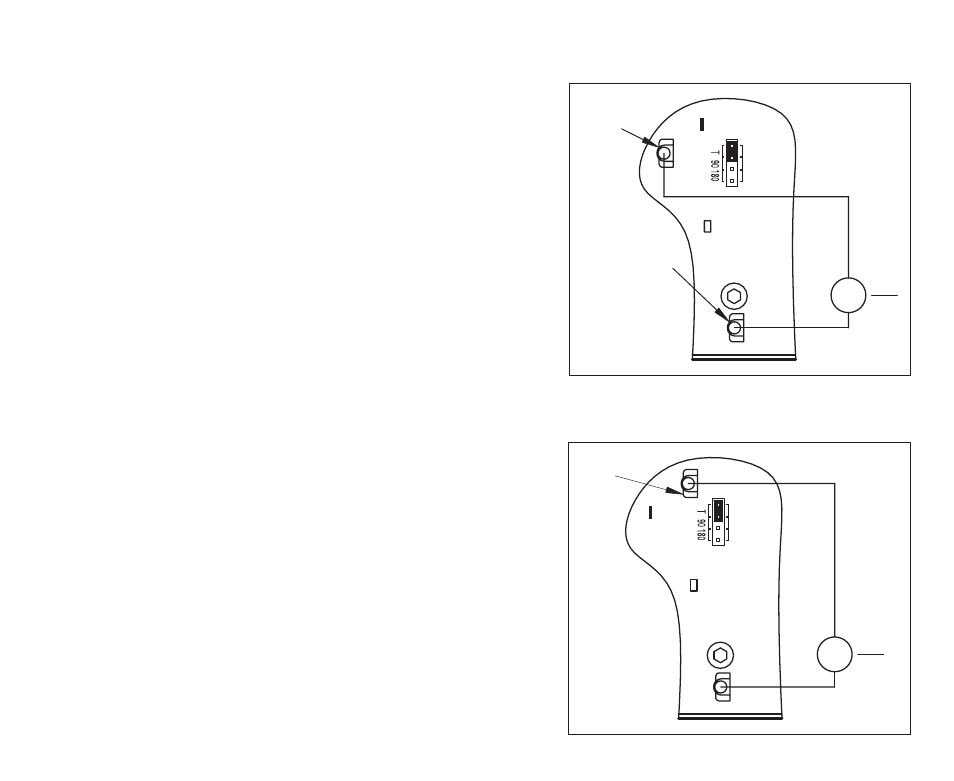

DC Tach-Generator Connection – A DC tach-generator

can be used for load regulation of 1% of the set speed.

Note: Jumper J2 must be set to the “T” position for

tach-generator operation. Connect the tach-generator

as follows.

Application Notes – 1. The tach-generator input circuit is

designed for a 7 Volt or 50 Volt per 1000 RPM DC tach-

generator used with an 1800 RPM motor. 2. Initially set the

IR Comp Trimpot fully counterclockwise. Once the tach-

generator is connected, the IR Comp Trimpot may be

increased for additional speed stabilization.

6.9.1 Seven (7) Volt per 1000 RPM Tach-Generator –

Connect the tach-generator positive lead (+) to

Terminal “T” and the negative lead (-) to Terminal

“I2”, as shown in Figure 8.

6.9.2 Fifty (50) Volt per 1000 RPM Tach-Generator –

Connect the tach-generator positive lead (+) to

Terminal “B” and the negative lead (-) to Terminal

“I2”, as shown in Figure 9.

6.9.3 Other Tach-Generator Voltages – The tach-gener-

ator input circuit is designed for a 7 Volt or 50 Volt

per 1000 RPM DC tach-generator used with an

1800 RPM motor. For a tach-generator other than 7

Volts or 50 Volts per 1000 RPM, or for a motor

other than 1800 RPM, an external 1/2 Watt resistor

(RT) must be installed. Install RT in series with the

18

B

PWR ON

I2

T

DC Tach-Generator

-

+

7V

G

1000

Terminal "T"

Terminal "I2"

J2

FIGURE 8 – DC TACH-GENERATOR CONNECTION

(7 VOLTS PER 1000 RPM)

B

PWR ON

I2

T

1000

G

50V

DC Tach-Generator

-

+

Terminal "B"

J2

FIGURE 9 – DC TACH-GENERATOR CONNECTION

(50 VOLTS PER 1000 RPM)