Icspa3-b1n (b2n) h (m) b3h (m), Drawing no, Z-axis cables x-axis, y-axis cables – IAI America NS User Manual

Page 4

X-axis Nut-rotation Type Cartesian Robot – High-precision 3-axis Specification,

Z Base Mount

ICSPA3-B1N (B2N)

H (M) B3H (M)

Drawing No.

Z-axis: ISA, etc.

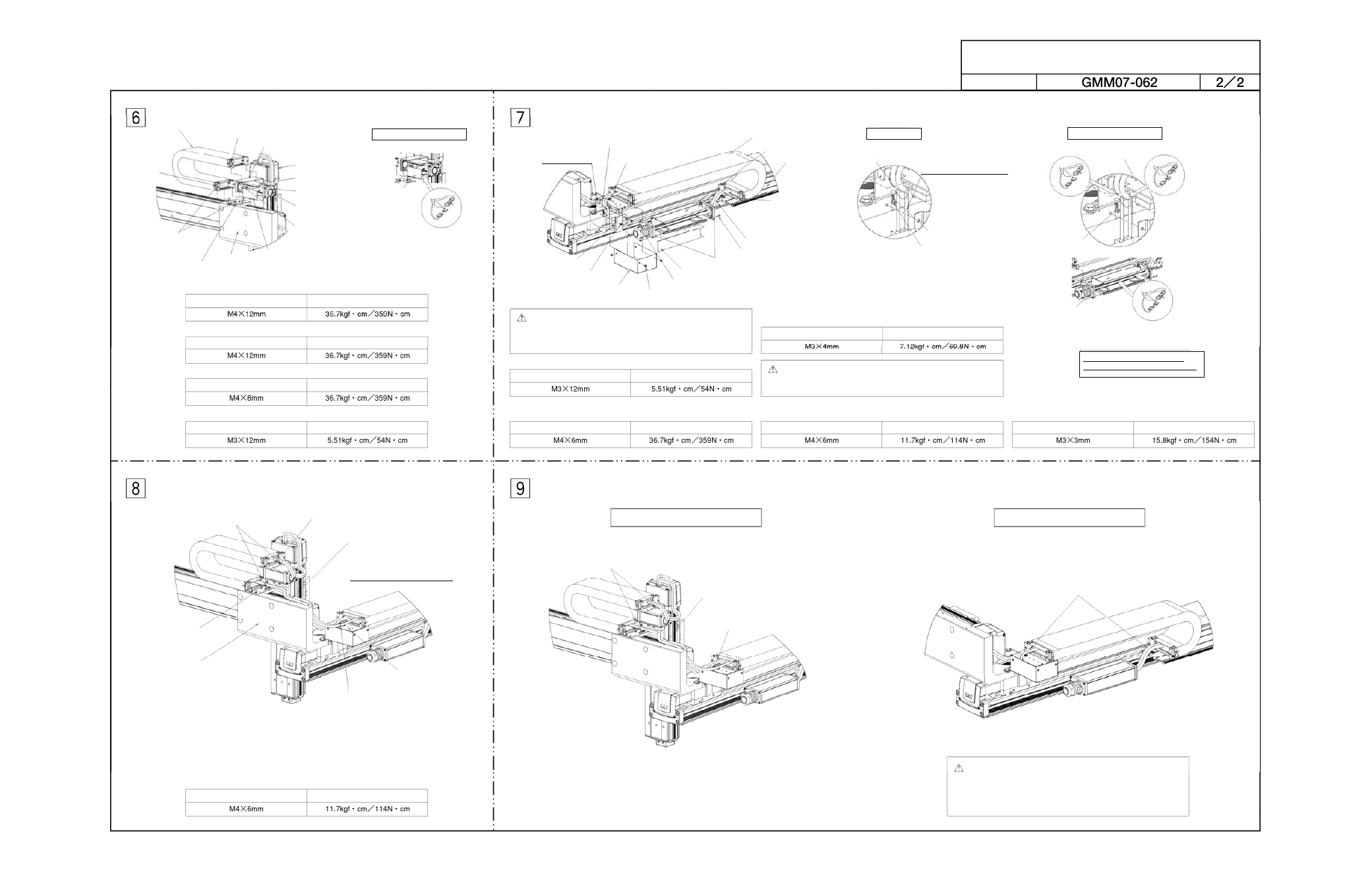

[Installation of cable track 2 [16] on track support bracket [14]]

[Installation of cable track 2 [16] on XY bracket [1]]

[Installation of cable track 2 [16] on track mounting bracket 2 [15]]

[Installation of box cover 2 [18] on connector box 2 [17]]

Caution: The cables for X-axis (axis 1), Y-axis (axis 2) and Z-axis

(axis 3) are placed in tracks. Install each cable correctly.

[Cable markings]

X-axis (axis 1): 1 Y-axis (axis 2): 2 Z-axis (axis 3): 3

[Installation of tie-mount on track mounting bracket 1 [2]]

[Installation of tie-mount in T slot of guide rail [3]]

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head button bolt M4x6

+ hexagonal nut (1 set)

Install in the T slot of the Y-axis.

[Installation of tie-mount in track mounting bracket 2 [15]]

[Installation of tie-mount on track support bracket [14]]

[Installation of tie-mount in T slot of XY bracket [1]]

[Installation of tie-mount on track mounting bracket 1 [2]]

Z-axis cables

X-axis, Y-axis cables

[16] Cable track 2

Hexagonal socket head bolt M4x8 (2 pcs)

[15] Track mounting bracket 2

Hexagonal

socket head

bolt M4x12

Hexagonal socket head bolt

M4x12

+ hexagonal nut (2 sets)

[14] Track support bracket

[1] XY bracket

[19] Joint cover 2

Hexagonal socket head bolt

M3x12 (8 pcs)

[8] Grommet with film

[18] Box cover 2

[17] Connector box 2

[17] Connector

box 2

Cable connector connection

Connector joint for

ISPA M cable and

PG cable (LS cable)

Hexagonal socket head bolt

Tightening torque

Hexagonal socket head bolt

Tightening torque

Hexagonal socket head bolt

Tightening torque

Hexagonal socket head bolt

Tightening torque

Detail view of A

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4x6 (1 set)

Cable inside track

[Installation of box cover 1 [6] on connector box 1 [5]]

[Installation of cable guard [10] on XY bracket [1]]

[Installation of metal cover [11] on track mounting bracket 1 [2]]

Caution: Since the hexagonal holes in thin-head bolts are small,

the hexagonal holes may be damaged depending on the

tightening method. Exercise due caution when tightening

thin-head bolts.

Hexagonal socket head button bolt

Place the X-axis cable and

PG cable (LS cable) into

the cable guard [10] and

take them out from the top.

Connector joint for

ISPA M cable and

PG cable (LS cable)

Ground terminal

Connector joint for cable inside track

and controller-actuator cable

[Installation of ground terminal on [1] XY bracket]

[5] Connector box 1

[3] Guide rail

Tie-mount KR5G5

(by HellermannTyton)

+ hexagonal socket head

button bolt M4x6 (1 set)

Hexagonal socket head bolt M3x12 (8 pcs)

[6] Box cover 1

[7] Joint cover 1

[9] Controller-actuator cable with cable fix cap

Thin-head bolt M3x12 (4 pcs)

[11] Metal cover

[10] Cable guard

Hexagonal socket

head bolt M4x6

(2 pcs)

[2] Track mounting bracket 1

Hexagonal socket head bolt

Tightening torque

Hexagonal socket head bolt

Tightening torque

Tightening torque

Tightening torque

Thin-head bolt

Hexagonal socket head bolt

Tightening torque

Hexagonal socket head bolt M3x3

Ground terminal

Cable inside track

Detail view of A

Cable connector connection

[5] Connector box

Connector joint for

NS M cable and

PG cable (LS cable)

[2] Track mounting bracket 1

[4] Cable track 1

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4x6 (2 sets)

[15] Track mounting bracket 2

[14] Track support bracket

[1] XY bracket

[2] Track mounting bracket 1

Tie-mount KR5G5 (by HellermannTyton)

+ hexagonal socket head button bolt M4x6 (1 set)

Hexagonal socket head button bolt

Tightening torque

Secure the cables using wraps.

Secure the cables using wraps.

Secure the cables using wraps.

Secure the cables using wraps.

Caution: Secure the wires to prevent the cables and connectors

from contacting each axis when the axis is moved over its

entire stroke.

When manually moving the actuator with brake, connect

the controller, supply the power, and then release the brake

release switch (by turning the switch to the RLS side).

Make sure the numbers on the

connectors to be connected match.