Harrington Hoists and Cranes ER Large Capaciy Hoist - (ER1) User Manual

Page 14

14

Table 5-3

Hoist Inspection Methods and Criteria

Use this table in conjunction with Table 5-3 of the EROM. The entries in this table replace in their entirety

the corresponding entries in Table 5-3 of the EROM.

Item

Method

Criteria

Action

Motor Brake

Measure, Visual

Motor brake gap should be adjusted to the

distance shown in

Table 6-3

before measuring

the brake wear. Brake lining dimension “A”

should not be less than discard value listed in

Table 5-6

. Refer to

Section 6.3

of the

EROM

for

gaining access to motor brake and for adjustment

and inspection procedures. Braking surfaces

should be clean, free of grease/oil and should not

be glazed.

Adjust, Repair or

Replace as

required.

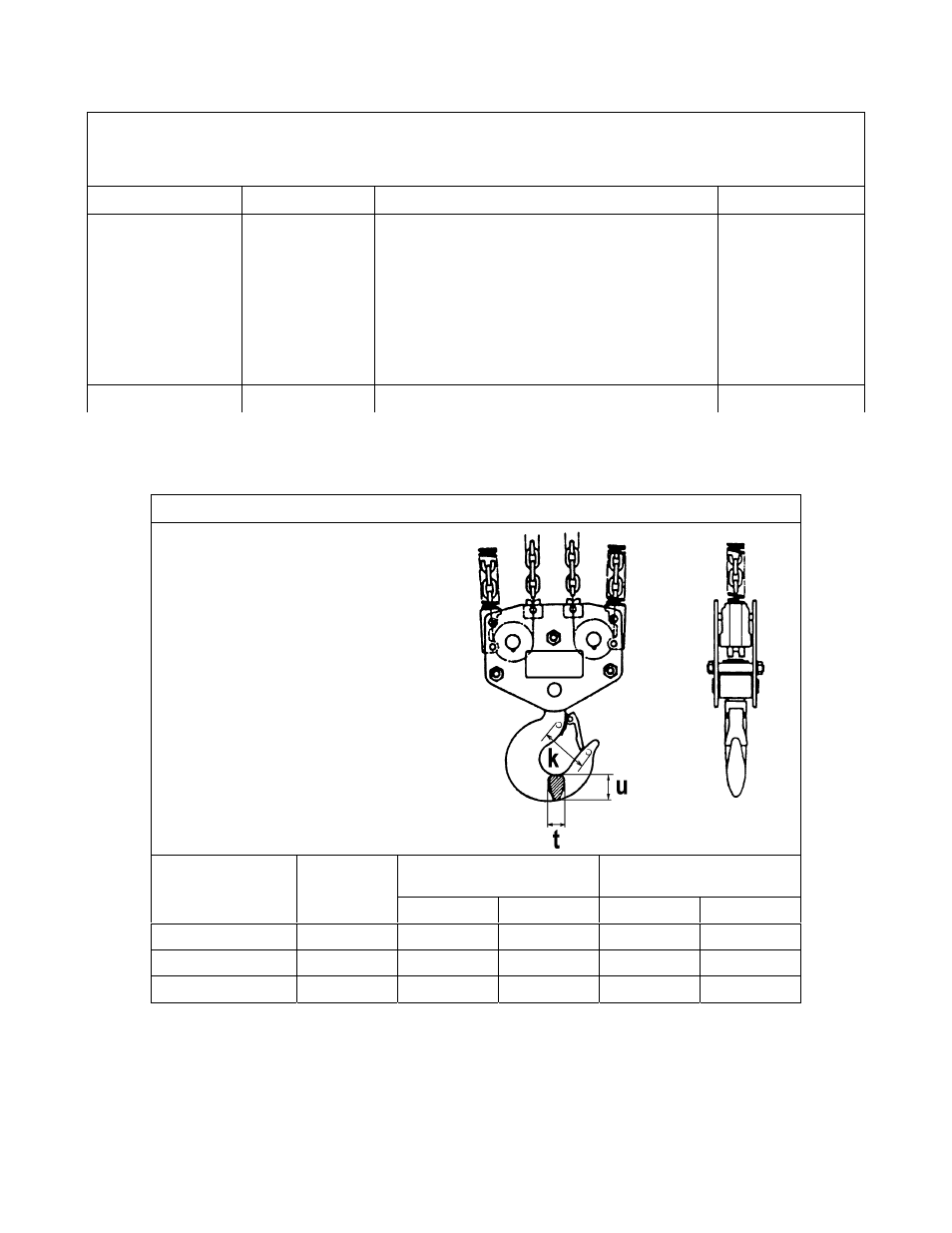

Table 5-4

Top Hook & Bottom Hook Dimensions

“k” Measured When New:

Top: _________________________

Bottom: ______________________

"u" Dimension

inch (mm)

"t" Dimension

inch (mm)

Capacity Code

Nominal "k"

Dimension*

inch (mm)

Standard

Discard

Standard

Discard

080S, 100L, 100S

4.72(120)

2.87(73)

2.60(66)

1.89(48)

1.69(43)

150S

5.04(128)

3.43(87)

3.07(78)

2.36(60)

2.13(54)

200S

5.57(141.5)

3.92(99.5)

3.54(90)

2.76(70)

2.48(63)

* These values are nominal since the dimension is not controlled to a tolerance. The "k"

dimension should be measured when the hook is new - this becomes a reference measurement.

Subsequent measurements are compared to this reference to make determinations about hook

deformation/stretch. See

Section 5.7

of EROM, “Hooks - Stretch”.