Ransburg, Rea automatic applicators - maintenance – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 42

6. Insert the bushing nut into the rear of the body.

Using the 20049-00 Spanner Wrench securely

tighten the bushing nut into the body.

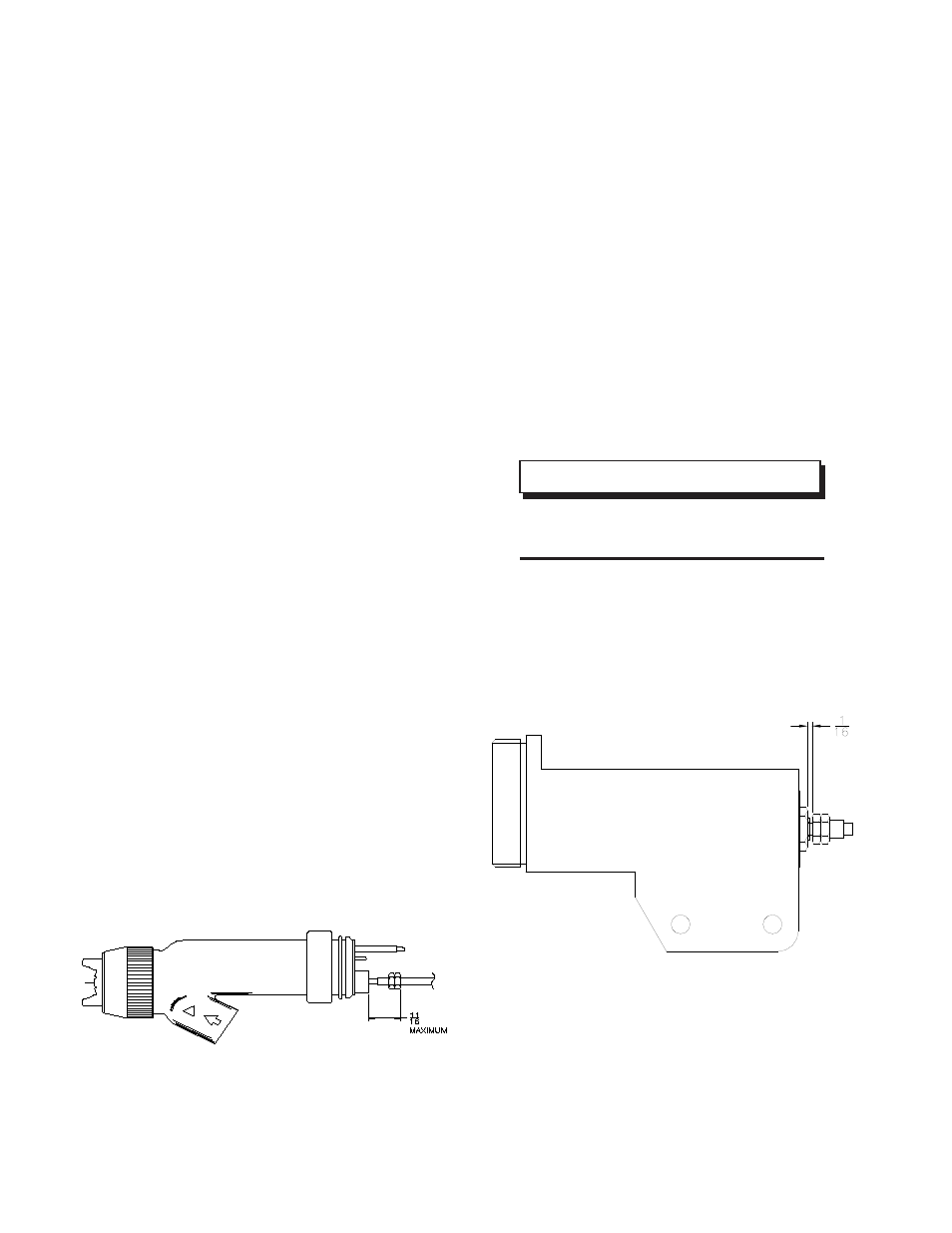

7. Pull the needle shaft back into an actuated

position. Screw the trigger adjustment nut onto

the needle shaft until there are no more threads.

8. Screw the extension rod on the needle shaft

until the hex of the extension rod is flush against

the hex of the trigger adjustment screw. (Using

T-Shaped Gauge on 19749-00, adjust to the

11/16-inch maximum dimension shown in Figure

10.)

9. Using two (2) 3/8” wrenches, tighten the two

(2) hexes against each other to prevent movement

of the parts.

10. Lubricate the piston assembly with LSCH0009-

00 dielectric grease.

11. Insert the piston assembly into the rear of the

body, through the bushing nut.

12. Slide the gasket onto the barrel assembly.

13. Place the barrel assembly onto the front of

the body. Making sure that the extension rod slides

STRAIGHT through the body.

14. Tighten the retaining ring to the body using the

19749-00 Spanner Wrench.

17. Push the extension rod fully forward to seat

the electrode into the fluid nozzle.

18. Screw onto the extension rod jam nut and the

air valve adjusting nut.

19. Position the jam nut 1/16-inch from the end of

the piston assembly.

20. Tighten the nuts against each other to prevent

movement (see Figure 11).

21. If the extension rod rotates while you are tight-

ening the nuts, hold it using an adjustable wrench

on the flats.

Figure 10: Rod and Trigger Adjustment Nuts

(Do not exceed the 11/16 maximum dimension

shown in this figure)

NOTE

> The hex nut and air valve adjust nut

control your air before fluid adjustment.

22. Install the two (2) springs.

23. Install the rear piston housing.

Figure 11: Air Before Fluid Adaptor

(Piston Housing not shown for clarity)

Ransburg

REA Automatic Applicators - Maintenance

38

AA-99-02.5