Ransburg, Troubleshooting guide (cont.), Rea automatic applicators - maintenance – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 29

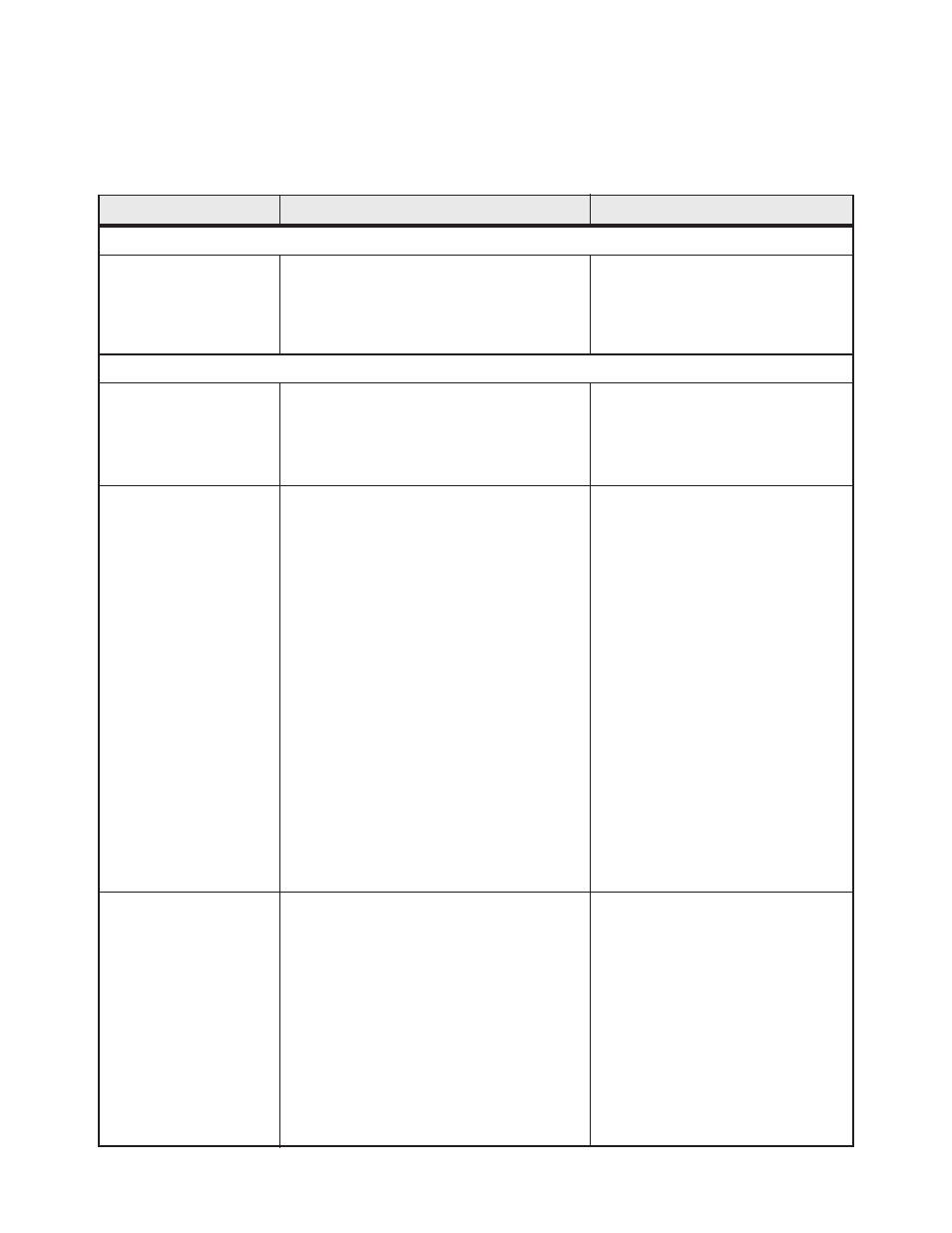

TROUBLESHOOTING GUIDE (Cont.)

Wrap Back

Improper or No HV

1. Improper target ground

2. Improper booth exhaust

3. Excessive atomizing air

1. Faulty cable connections

2. Faulty transformer assembly

3. Improper or no ground

4. Faulty barrel/cascade assembly

5. Faulty low voltage cable

6. Faulty high voltage cable

7. Faulty control unit

8. Check fuses

9.

>

IS THE POWER TURNED ON?

>

IS THE ATOMIZING AIR

TURNED ON?

>

IS THE (RED LIGHT) TRANS-

FORMER ON?

>

IS THE PAINT TOO CONDUCTIVE?

10. Paint in air passages

1. Trace and correct.

2. Trace and correct.

3. Reduce fan and atomization

pressure.

1. Check and secure at the

applicator and at the control

unit.

2. Replace.

3. Trace and correct.

4. Replace.

5. Replace.

6. Replace.

7. See the Control Unit manual.

8. Replace.

9.

10.Clean passages with soft

bristled brush

General Problem

Possible Cause

Solution

High Current Draw

1. Paint in air passages

2. Dirty dump line

3. Paint in dump line

4. Dirty applicator exterior

1. Clean passages with soft

bristled brush

2. Clean or replace dump line;

always use lines.

3. Review air push cycle

4. Clean with appropriate sol-

vent and install new applicator

cover.

ELECTRICAL

Fluid (constant at

nozzle)

1. Worn or damaged fluid nozzle seat

2. Worn or damaged needle/electrode

3. Nozzle not secure

4. Trigger valve needle seat

1. Replace fluid nozzle.

2. Replace.

3. Tighten.

4. Rebuild valve.

LEAKAGE (Cont.)

Ransburg

REA Automatic Applicators - Maintenance

25

AA-99-02.5