Ransburg, Troubleshooting guide, Rea automatic applicators - maintenance – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 28

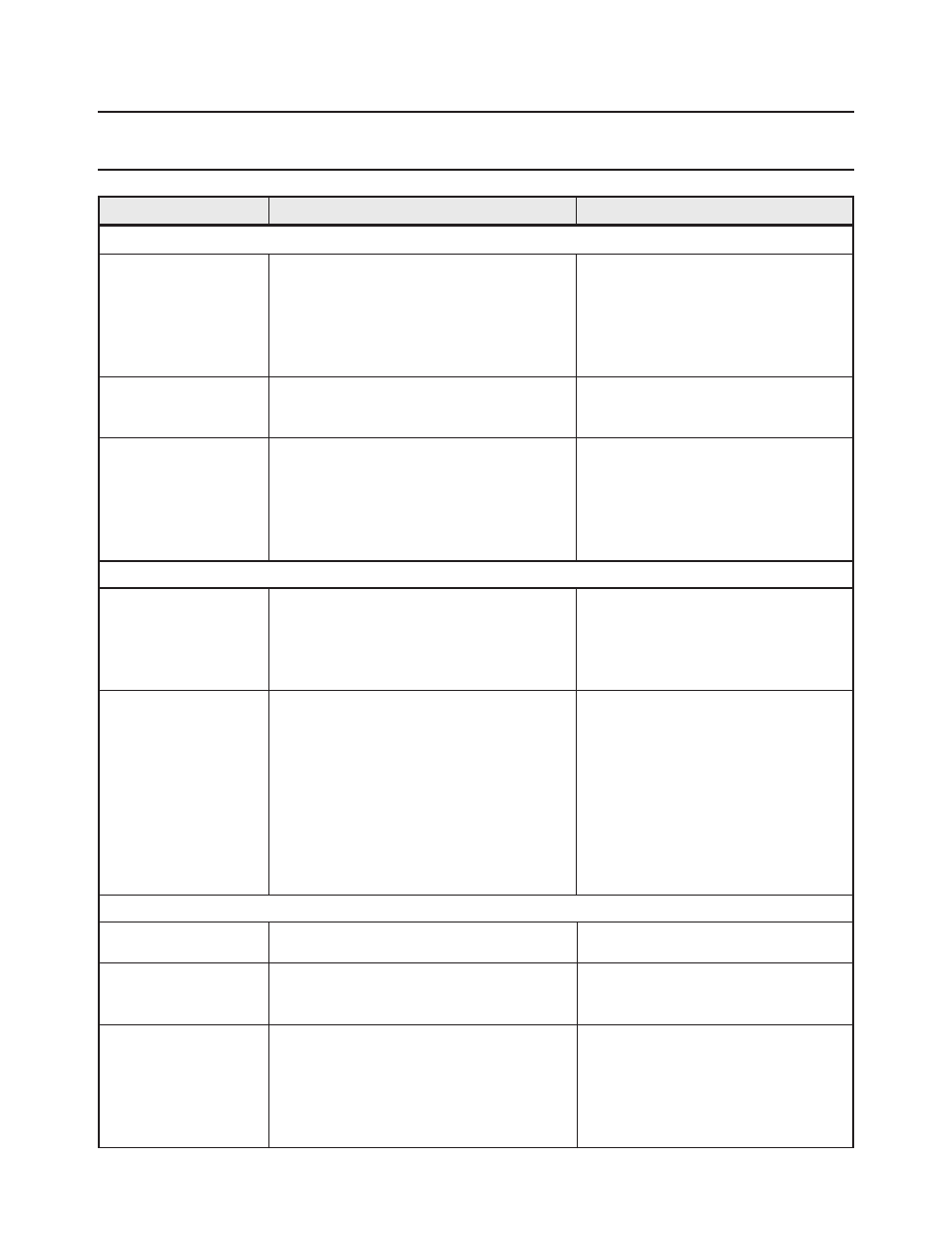

Pattern will not

shape

Pattern heavy at

one end

Extremely heavy

spitting or severely

deformed pattern.

1. Clogged or faulty fan valve remote

fan air line

2. Air passages in applicator or air

feed lines clogged

3. Worn, faulty or clogged air cap

1. Clogged or faulty air cap

2. Clogged or faulty fluid nozzle

1. Wrong air cap/fluid nozzle

combination

2. Timing of fluid on and air on is not

adjusted

1. Clean, replace or repair.

2. Blow out.

3. Clean or replace.

1. Clean or replace.

2. Clean or replace.

1. Ensure proper fluid nozzle/air

nozzle pressure reducer

combinations (see chart).

2. Check programming se-

quence.

General Problem

Possible Cause

Solution

Air

Fluid

1. Air passages in applicator or air feed

lines clogged

2. Deficient source air

3. Paint in air passage

1. Clogged or faulty fluid nozzle

2. Clogged passages in applicator fluid

tube or fluid feed lines

3. Insufficient needle/electrode travel

4. Low source pressure

5. Clogged fluid filter

6. Clogged or obstructed ball valve or

fluid regulator

1. Blow out.

2. Increase.

3. Clean and blow out.

1. Flush or replace.

2. Flush.

3. Adjust (see “Trigger Nut

Adjustment”).

4. Increase.

5. Clean or replace.

6. Clean as required.

DEFECTIVE DELIVERY

LEAKAGE

Air

Fluid (at rear of

barrel)

Fluid

(sight at nozzle

when trigger is

released)

1. Loose or defective fittings

1. Packing, chevron seals and/or

needle /electrode shaft defective

1. Nozzle not secure

2. Trigger valve closing before fluid

nozzle valve

1. Tighten or replace.

1. Tighten needle or replace.

1. Tighten.

2. Check programming

sequence.

DEFECTIVE SPRAY PATTERN

TROUBLESHOOTING GUIDE

Ransburg

REA Automatic Applicators - Maintenance

24

AA-99-02.5