Ransburg – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 32

NOTE

>

If the fluid nozzle is replaced, there is

a good chance that the needle/electrode

assembly will need to be replaced, too.

C A U T I O N

!

>

DO NOT use dielectric grease inside the

probe assembly. Air must be able to flow freely

through this assembly.

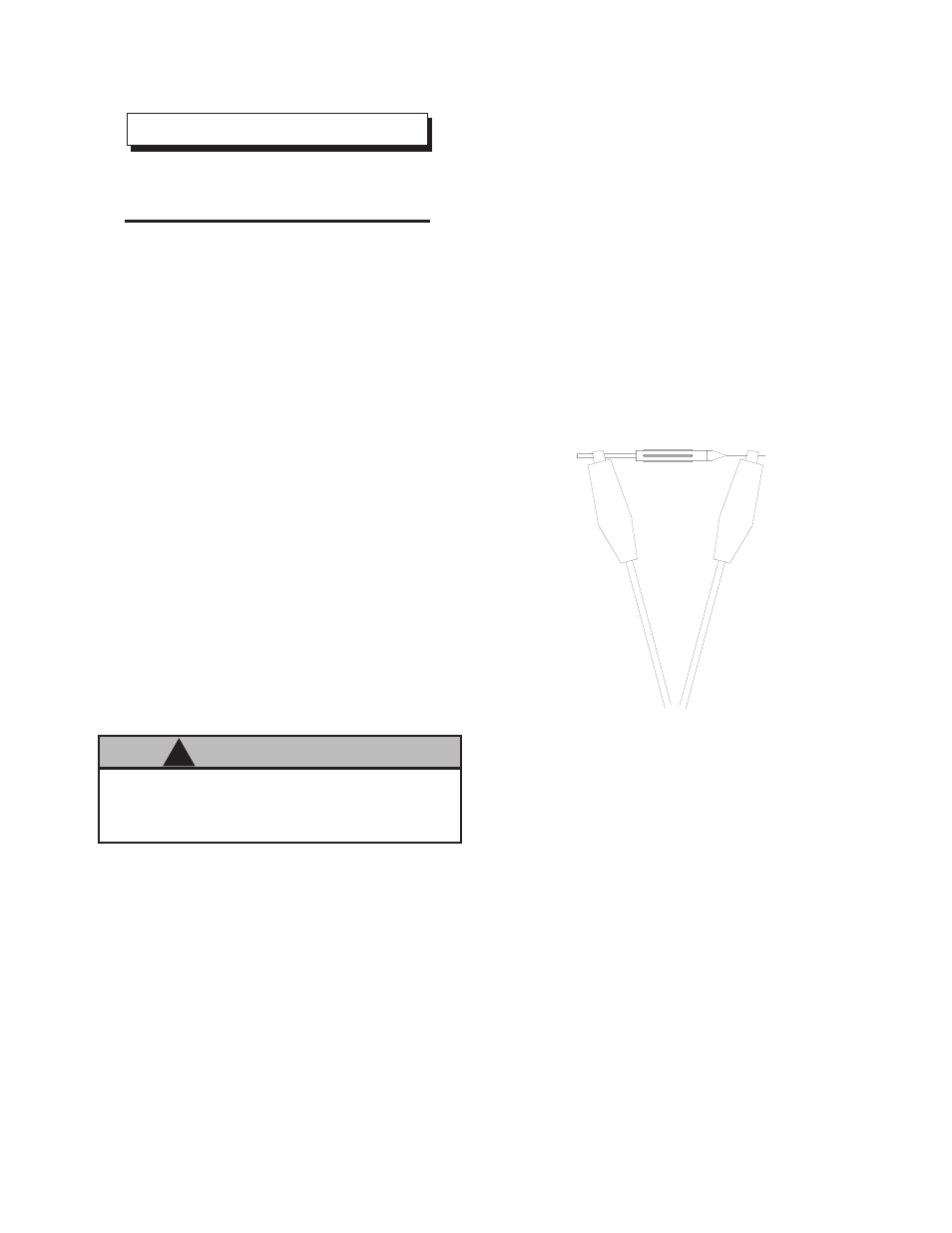

Figure 6: Testing Resistive Electrode

Needle / Electrode - REA 9000W

Only

1. Unscrew probe retaining nut and pull probe

straight out of the probe holder body.

2. Unscrew the rear plastic plunger nut of the

probe assembly and remove.

3. Gently tap the probe body against your hand

until the needle assembly falls loose. Pull the

needle assembly out of the probe body.

4. By hand, unscrew (counter-clockwise) or

where necessary gently use needle nose pliers

on the needle/electrode ridges to remove it from

the needle shaft assembly. Clean as necessary

using appropriate cleaning procedure.

5. Inspect needle assembly components for signs

of high voltage arcing. Replace if necessary.

6. If LREA4001 Resistive Electrode is being

replaced, it must be trimmed to the proper length.

Reassemble the probe with the new electrode.

Trim the electrode wire 1/16-inch from the end of

the probe body.

To Test - (REA 9000W)

1. Install electrode on front end of an available

18865-04 needle shaft. Be sure that electrode

is completely seated for proper contact between

metal shaft and conductive threaded insert in rear

of resistor.

2. Using a VOM meter that will read 15 meg-

ohms accurately, connect one meter lead to the

metal needle shaft and the other lead to the wire

at front of electrode. Electrode should be 14.5

to 19 megohms (nominal 15 megohms at 9 volts

or 11 to 17 megohms at 1000 volts). Electrodes

outside this range must be replaced (see Figure 6).

Ransburg

REA Automatic Applicators - Maintenance

28

AA-99-02.5