Ransburg – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 21

> The atomization and fan air line should

always lead the trigger signal when the

applicator is on, and lag the trigger signal

when the applicator is off. Failure to follow

this procedure will cause applicator spits.

NOTE

To Install the REA 9000W or

REA 900A

1. Mount the applicator to the reciprocator bar.

It is recommended to use a keyed bar with 1/4”

Woodruff key. The applicator may be mounted

on bars from the size .98-inch diam. (25 mm) to

1.00-inch diam. (27 mm). Tighten the five (5)

mounting screws securely.

2. Run 1/4-inch ODT air line to the trigger line

fitting.

>

ALL fittings used must be noncon-

ductive. The use of electrical conductive

fitting may cause injury or fire.

W A R N I N G

!

3. Run 3/8-inch ODT or 1/2-inch ODT fluid line to

the applicator.

4. Connect atomization air and fan air lines. De-

pending upon atomization technology used, size

the line accordingly.

5. Install 1/4” ODT air line to shroud or probe

purge air. Set pressure between 5-10 psig.

6. Install 1/4-inch ODT air line for dump actuation.

7. Install 3/8-inch ODT

fluid line to dump out.

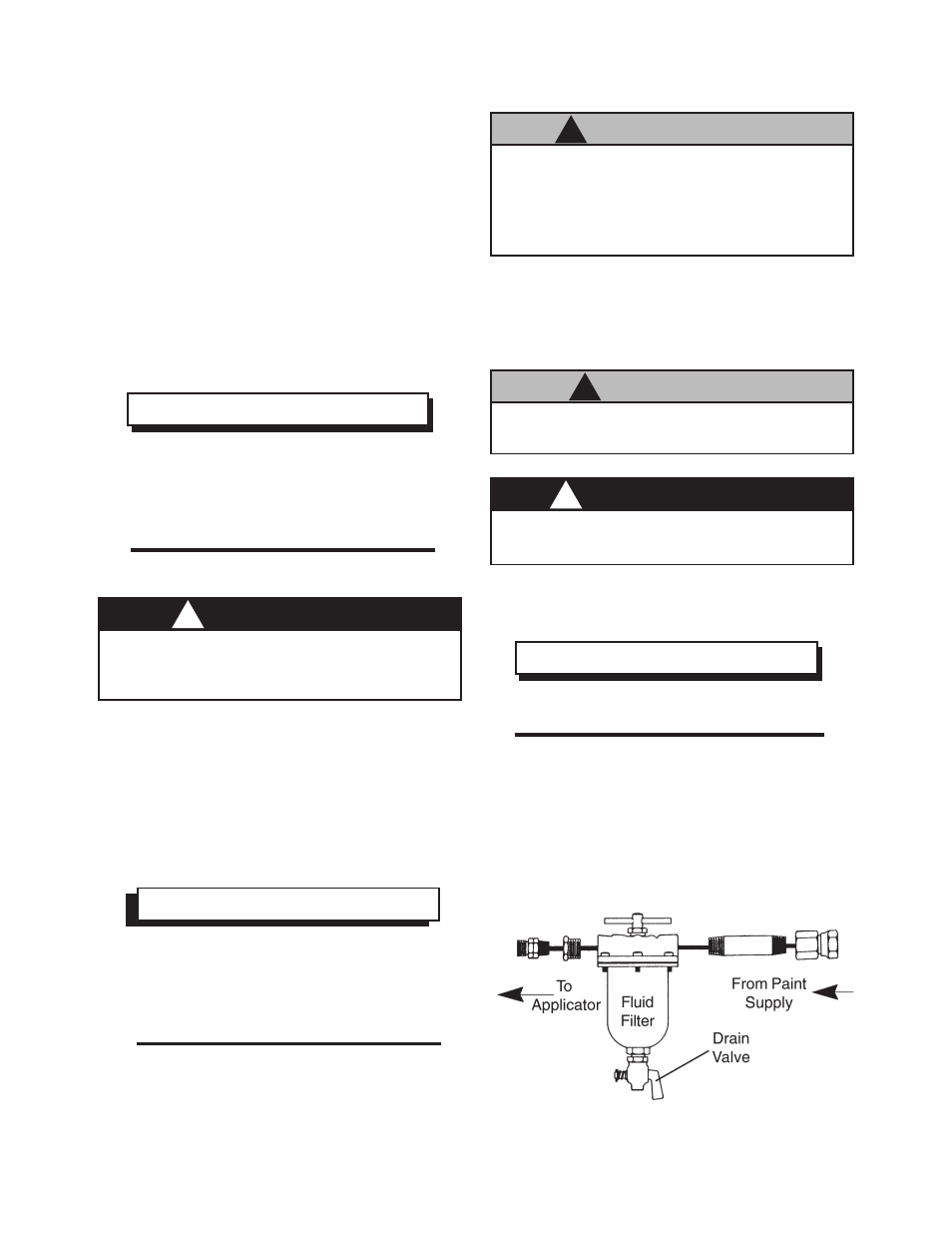

Figure 5: Typical Fluid Filter Installation

Filters

> Failure to use dump line will degrade col-

or change time and applicator performance.

C A U T I O N

!

>

For optimum finish quality use clean,

dry filtered air.

NOTE

>

Whenever the applicator is in the dump

or flush mode, the electrostatics must be off.

W A R N I N G

!

1. Install a fluid filter on the output of fluid supply,

as shown in Figure 5.

2. Detail depends on whether pressure tank,

pump unit, recirculating system, etc., is used. The

filter must be installed vertically with drain valve

down and arrow pointing in direction of flow.

> Failure to connect the shroud purge air line

on the REA 900A Gun can allow excessive

corona to build up within the shroud and cause

premature failure of the barrel and transformer

assemblies.

C A U T I O N

!

>

All fittings may be replaced with

alternate fittings, depending on your

installation. (See “Specifications”

previously discussed in the “Introduc-

tion” section, for female thread size.

NOTE

Ransburg

REA Automatic Applicators - Installation

17

AA-99-02.5