Ransburg, Air bushing / body disassembly, Air bushing / body assembly – Ransburg REA Automatic Applicators 77359, 76110, 77140 User Manual

Page 41

AIR BUSHING /

BODY DISASSEMBLY

C A U T I O N

!

> The piston housing is spring loaded. Use

care in disassembly.

(REA 9000R and 900A)

1. Remove piston housing from body.

2. Remove adjustment hex nut and air valve

adjustment nut from extension rod.

3. Remove retaining ring from body and pull the

C A U T I O N

!

> Pull barrel

STRAIGHT out from body or

bending of extension vale rod may occur.

barrel

STRAIGHT out.

4. Using pliers, grab the piston nut and pull the

piston o-ring, shaft valve piston, piston washer,

packing cup, piston and hex nut

STRAIGHT out

of the body.

5. Using the 20049-00 special wrench, remove

the bushing nut.

6. Remove the extension rod from the needle

shaft or use an extra extension rod. Insert the

hex end of the extension rod into a slot of the

bushing and pull straight out.

7. Using a 3/8-inch nut driver, remove the valve

seal retaining nut and o-ring.

AIR BUSHING /

BODY ASSEMBLY

(REA 9000R and 900A)

1. Insert a new o-ring into the valve seal re-

taining nut.

2. Using a 3/8” nut driver, tighten the valve seal

retaining nut into the body.

3. Insert a new o-ring into the groove on the front

of the bushing.

4. Place a new o-ring onto the o-ring groove on

the outside of the bushing.

5. Insert the bushing into the rear of the body

and firmly press into position.

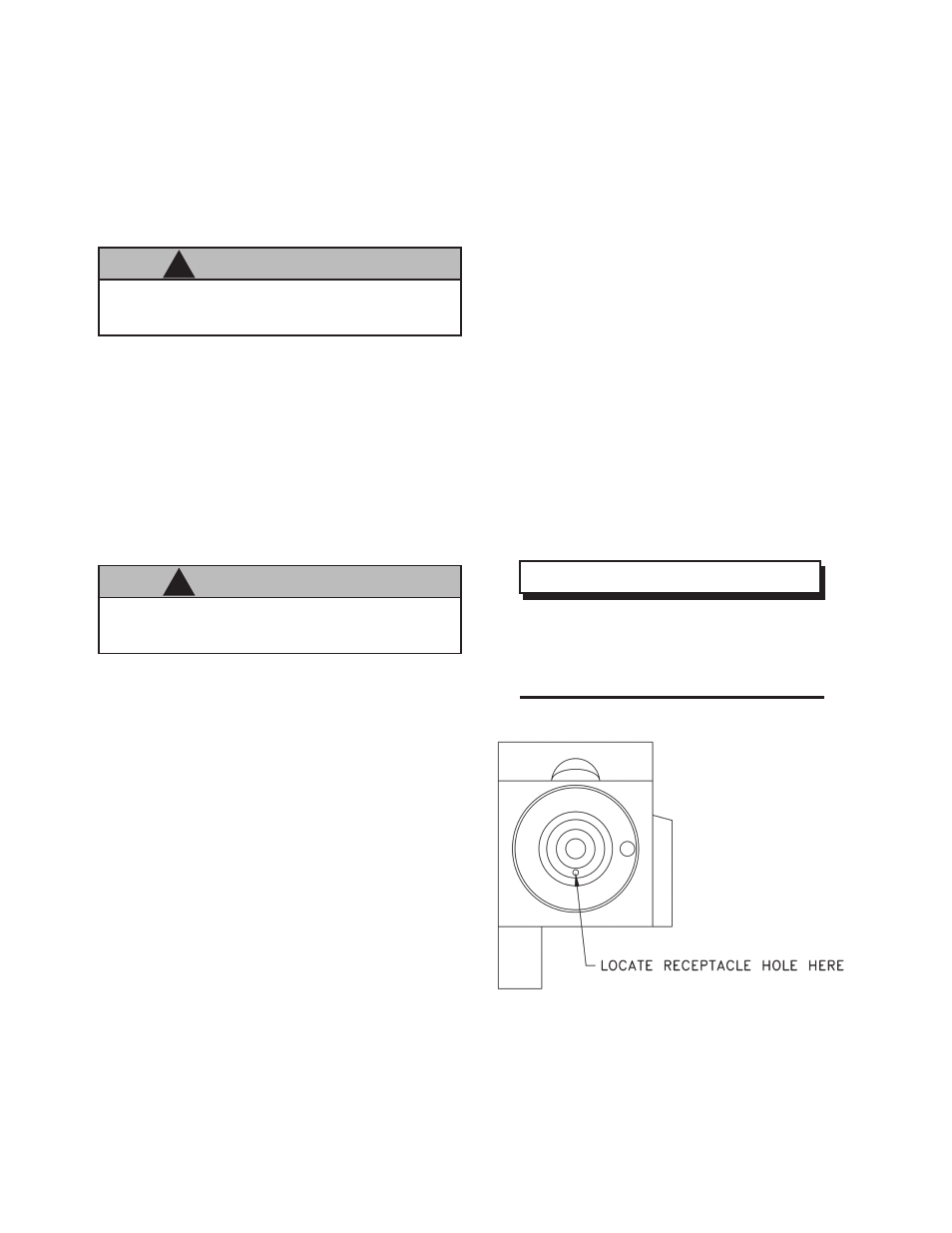

Figure 9: View of Rear Body

NOTE

> The bushing has a locator pin pressed

into the front. This pin must align with

the receptacle hole in the body (see

Figure 9).

Ransburg

REA Automatic Applicators - Maintenance

37

AA-99-02.5