4 nutrunner (tool) dimensions, 1 straight tool – FEC AFC1200 User Manual

Page 6

)(& ,QF

4.4

Nutrunner (Tool) Dimensions

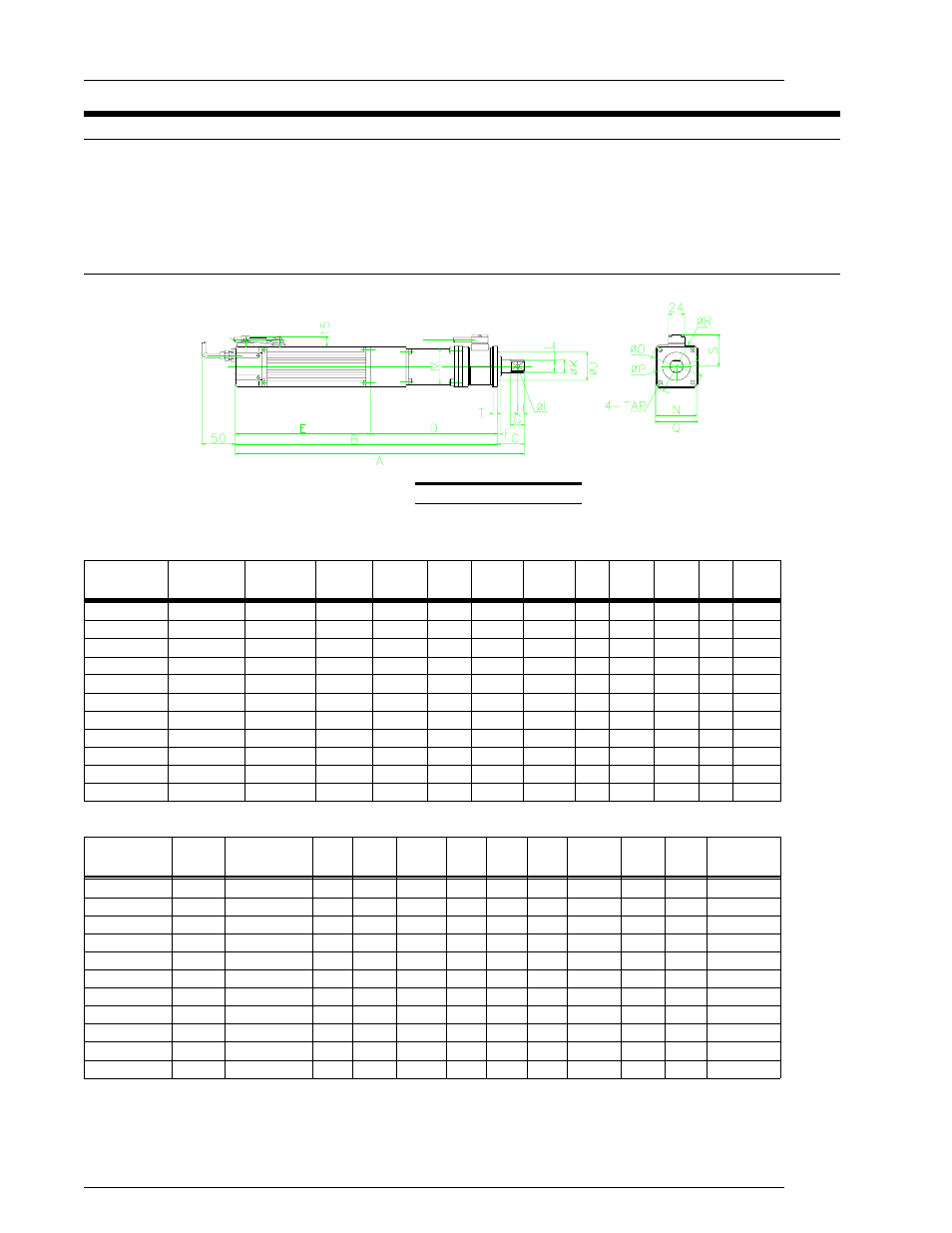

Tool dimensions and mounting specifications are critical in determining the design of the powerhead

that will house the tool assemblies. Caution must be taken to ensure that the tool assemblies do not

come in contact with any other assembly. Failure to provide adequate clearance may result in

inaccuracies in the monitoring capability of the system or possibly damage to the tool assembly.

Torque capabilities of each tool assembly are specified to aid in determining tool requirements.

4.4.1 Straight Tool

FIG. 4-4-1 Straight Tool

Numbers shown in brackets are in inches. All others shown in millimeters as the standard.

62

6.5

15

30

6

255

310

50

565

615

110

50

502M4-S

52

5.5

13

25

5

202.5

228

40

430.5

470.5

150

30

302M3-S

42

5.5

10

20

4

202.5

210

40

412.5

452.5

220

20

202M3-S

42

5.5

10

20

4

202.5

168

40

370.5

410.5

315

15

152M3-S

42

5.5

10

20

4

202.5

189

40

391.5

431.5

395

13

132M3-S

42

4.5

8

16

4

202.5

180

40

382.5

422.5

500

8

801M3-S

42

4.5

8

16

4

202.5

145

40

347.5

387.5

790

6

601M3-S

42

4.5

8

16

4

147.5

180

40

327.5

367.5

500

4

401M2-S

32

3.5

5

12

4

140

159

30

299

329

250

4

401M1-S

32

3.5

5

12

4

140

159

30

299

329

500

2

201M1-S

32

3.5

5

12

4

140

159

30

299

329

500

1

101M1-S1

J

I

H

G

F

E

D

C

B

A

SPEED

(rpm)

TORQUE

(kgm)

DFT-

TYPE

13

15

56

110

80

M10

90

110

80

73

25.4 (1.00)

32

502M4-S

10

12

54

102

76

M8

87

102

76

73

19.0 (.748)

25

302M3-S

6

8

47

80

62

M8

68

80

62

54

15.8 (.622)

20

202M3-S

6

8

47

84

62

M6

68

84

62

54

15.8 (.622)

20

152M3-S

5.5

6

47

80

60

M6

68

80

60

54

15.8 (.622)

20

132M3-S

5

6

43

80

60

M6

62

74

54

51

12.7 (.500)

16

801M3-S

5

6

43

80

60

M6

62

74

54

51

12.7 (.500)

16

601M3-S

3.2

6

43

80

60

M6

62

74

54

51

12.7 (.500)

16

401M2-S

3

5

36

55

40

M4

46

55

40

38

9.5 (.374)

12

401M1-S

3

5

36

55

40

M4

46

55

40

38

9.5 (.374)

12

201M1-S

1.9

5

36

55

40

M4

46

55

40

38

9.5 (.374)

12

101M1-S1

WEIGHT

(kg)

T

S

R

Q

TAP

P

O

N

M

L

K

DFT-

TYPE

Chapter 4: System Setup and Wiring

Page 4-6