Teledyne IR-7000 - Non-dispersive infrared series User Manual

Page 24

Operational Theory 2

IR7000

16

Teledyne Analytical Instruments., - Rev. 3

sample gas is to be returned to the process or flare, suitable back

pressure controls should be employed to ensure the analyzer vents

at a constant pressure.

2.5

Internal Gas Handling System

The gas handling system inside the analyzer is similar in principle for

all models. The following information describes the internal gas handling

system for the IR7000 model. Variations for other models will be noted.

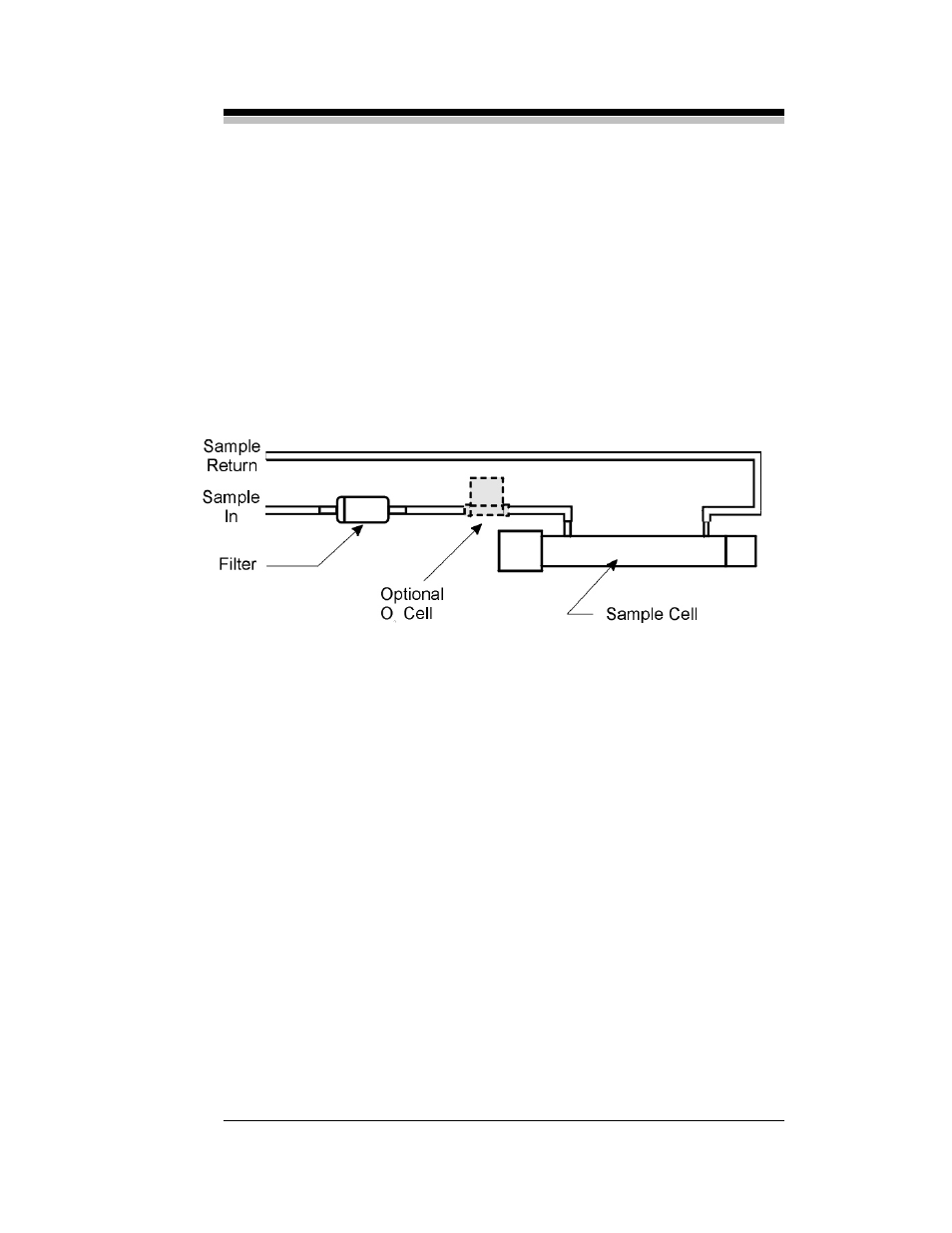

Figure 2-4 is a diagram of the internal components and plumbing for

directing calibration or sample gas through the analyzer.

Figure 2-4: Sample Path Through Analyzer – Standard Model

Either sample or calibration gas is delivered under pressure to the

analyzer by the customer or LSC supplied sample system. The gas enters

the analyzer and passes through a 0.3-micron disposable filter to remove

any particulate matter. If an O

2

channel has been incorporated, the O

2

sensor is installed in series with the sample cell. The gas passes first

through the O

2

sensor and then through the sample cell and out to the

sample return.

In the portable model, a 12V DC mini-pump is installed between the

disposable filter and the sample cell. Otherwise the internal plumbing is

the same.

The internal gas handling systems installed in the split-architecture

and explosion proof models vary according to the specific application. In

general, the plumbing is the same as the standard models with the

following exceptions:

•

Metal tubing and fittings replace Teflon lined PVC tubing