Maintenance – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 43

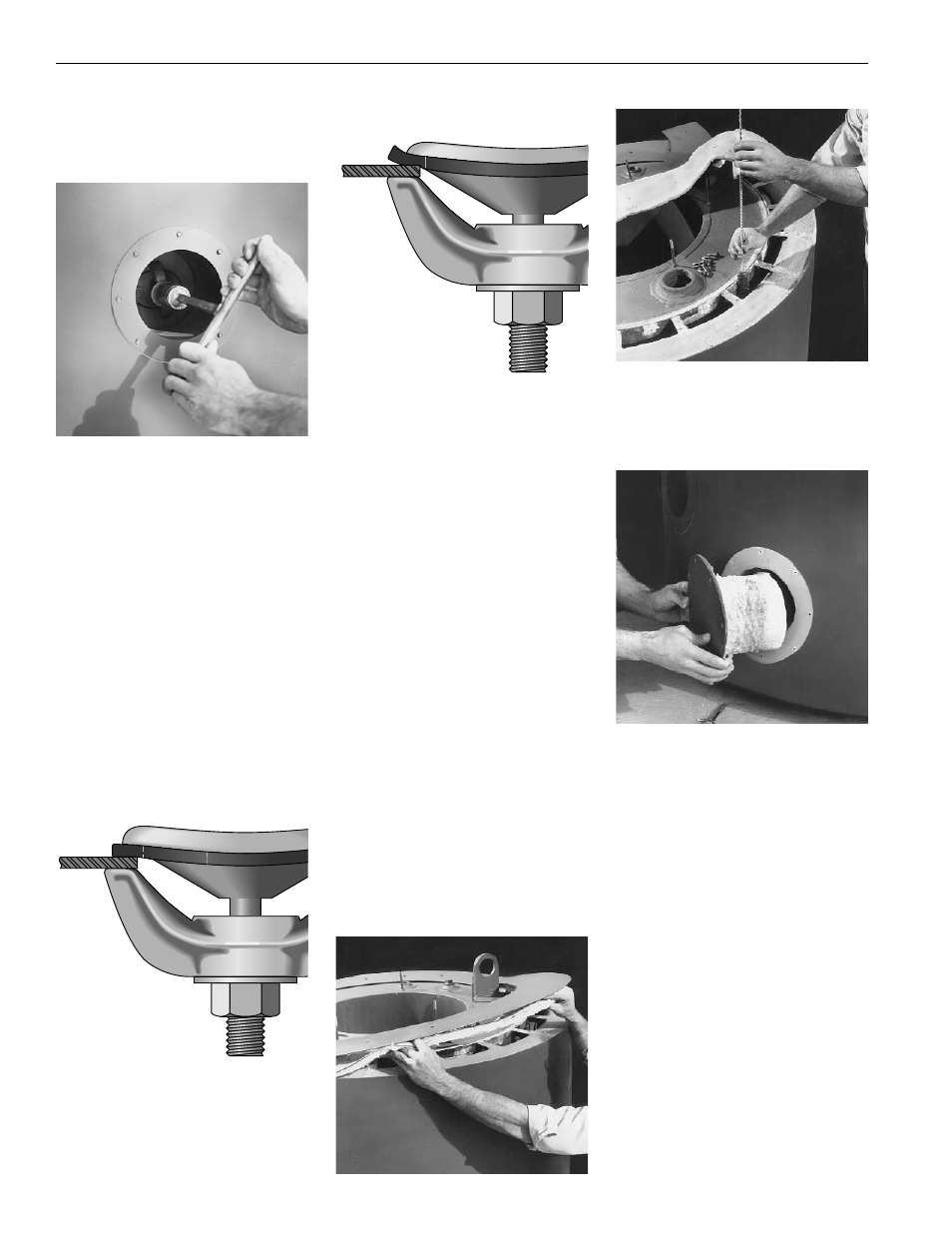

g) Replace handhole gaskets

using the following procedure:

1) Remove the handhole assembly

using a 1-1/4" tee handle wrench or

1-1/4" socket wrench.

Removing handhole assembly with a

Tee Handle Wrench

2) Remove the old gasket and thor-

oughly clean the surface on the boil-

er and the plate.

3) Fit the handhole assembly as

follows:

a) Place the gasket on the handhole

plate and ensure that it is seating

correctly. Do not use any grease,

lubricant, or adhesive.

b) Position the plate in the boiler.

Set the yoke and tighten the secur-

ing nut sufficiently enough to provide

a snug fit. Verify the position of the

plate in the boiler, then make it hand

tight and then snug with wrench

about 1/4 turn. Do not compress

excessively.

Illustration shows correct pressure

on gasket

c) If the gasket leaks while pres-

sure is being built up, tighten only

enough to stop leakage. Never

tighten more than necessary to

prevent leakage. Excessive

tightening may shorten the life of

the gasket.

d) Refill the boiler with fresh water.

NOTE

After a new Fulton Boiler has

been in operation for several

months, pieces of burned metal

will be found in the space at the

bottom of the boiler. These pieces

of metal are the remains of a light

gauge metal form which was used

during manufacture for forming

the boiler insulation. This is a

normal condition and does not

affect the efficiency or the life of

the boiler in any way.

Recommended Annual

Maintenance Schedule

a) Have combustion (CO

2

,O

2

, CO)

and input checked by trained

personnel.

b) Dirty flues can cause air flow

restrictions resulting in poor com-

bustion and loss of efficiency.

Clean flues as follows:

1) Remove the burner and flue

cover plate.

2. Wire brush flue passages.

3) Remove clean out plugs at low-

est part of unit and clean the bottom

of combustion chamber.

4) Remove all soot from the top,

and from the cleanout plugs at the

bottom with a vacuum cleaner.

5) Replace cleanout plugs carefully

so as not to damage insulation and

replace burner and flue cover plates.

c) Flush boiler out if necessary.

See Section 2 for proper procedure

for "Cleaning the Pressure Vessel."

d) Clean Water Probes - See Page

28 of this section for proper proce-

dure.

e) Provide annual inspection by a

qualified ASME Boiler inspector.

Maintenance

33-O 4/00

Remove burner and flue cover plate

Wire brush the flue passages.

Removing clean out plugs

Illustration shows over compressed

gasket