Maintenance – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 39

Maintenance

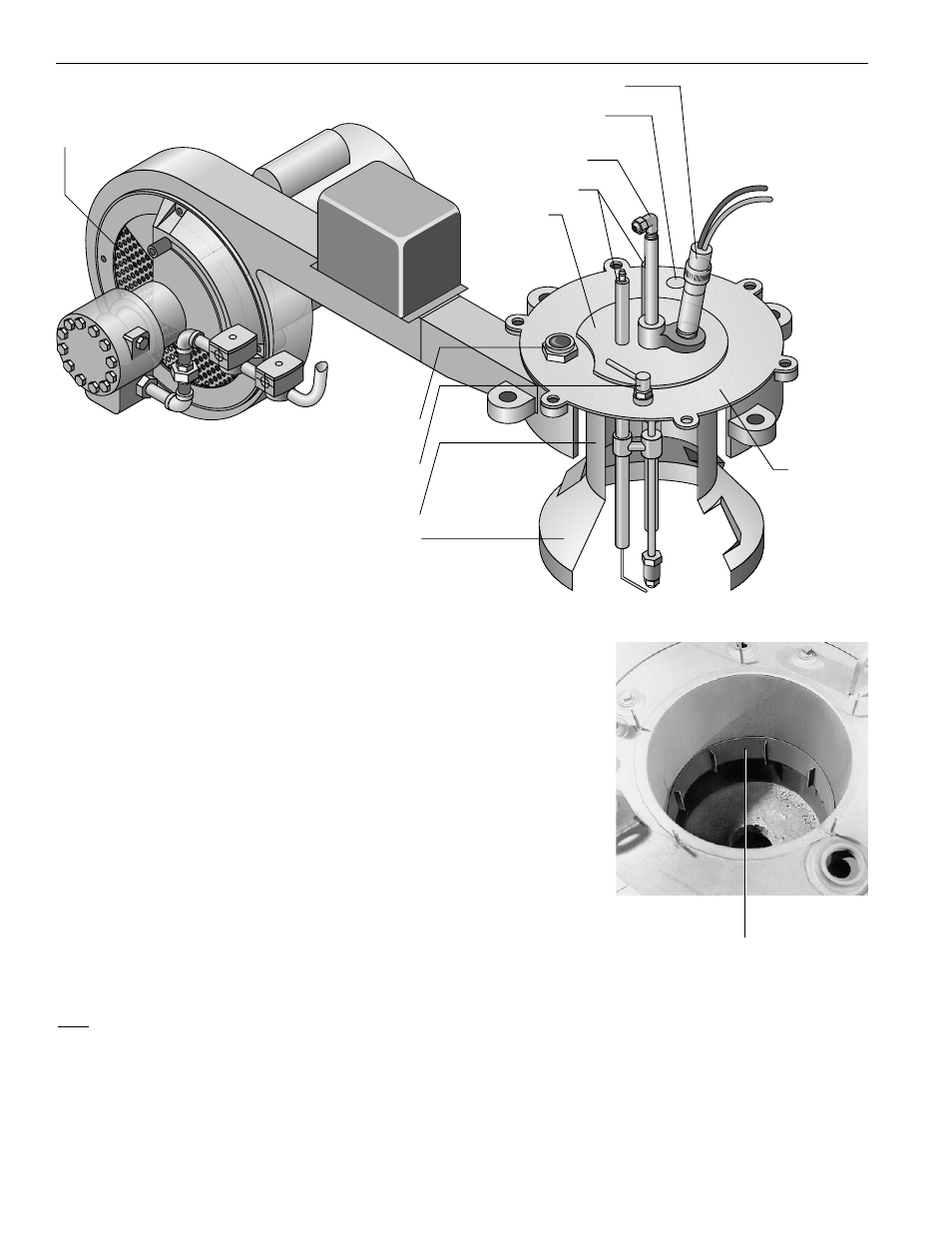

Flame Signal Detection for Fulton

Oil Fired Steam Boilers

a) It is essential to obtain optimum

flame signal detection for safe and

continual operation of the combus-

tion control relay.

b) If a scanner or cad cell is inopera-

ble, it may prove the detector is

working and only an adjustment to

the pilot flame is needed to improve

the signal.

c) If the scanner or cad cell is found

to be defective, replace .

Notes:

1) The scanner is located on the

outside edge of the burner top

plate for 20-60 HP.

2) For New York City installations

only: a non-adjustable oil pres-

sure regulator and gauge are sup-

plied upstream from the oil

valves.

d) For the RM7800 Series use a

keyboard display module or volt

meter, the flame safeguard will

require a 1.25 VDC signal to pull in

the main flame. Then a maximum

signal should be obtained on main

flame (5.0 VDC).

e) Adjustments to establish a good

signal may include the following

items:

1) Primary and secondary air

adjustments.

2) Realignment of the ignition elec-

trode.

Checking the Stainless Steel

Combustion Ring on Fulton

Oil Fired Steam Boilers

a) The stainless steel combustion

ring in Fulton oil fired boilers are

designed to bring quick and effec-

tive flame transfer to the fire

wall. The ring should fit securely

and tight against the furnace wall for

best results.

b) The ring should be inspected for

distortion in the event of poor com-

bustion which could result in flame

failures.

29-O 4/00

Stainless

Steel

Combustion

Ring

Primary

Air Gate

Secondary

Air Gate

Observation

Port

Blast Tube

Cad Cell (4–15 HP)

Electrodes

Oil Inlet

Scanner Location

(20–60 HP)

Burner

Plate

Air Deflector

Top Plate