Operation – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 32

Operation

Oil Burner Set Up

a) Open the oil line shut off valves.

b) Switch on the main power to the

burner. Depress the manual reset

button on the panel box.

c) To start the burner, turn on the

switch located on the panel box.

The blower motor will now start to

deliver the air into the furnace. As

the blower starts, the magnetic oil

valve is energized allowing the oil

pump to deliver fuel to the furnace

where it is ignited.

d) On Fulton 4-15 h.p. oil fired boil-

ers, the burner control sights the fire

from a cadmium sulfide photocell

located on top of the burner. If it

does not detect the flame in approx-

imately 15 seconds, it will go out on

safety lockout and shut down the

burner.

e) On Fulton 20-60 h.p. oil fired

boilers, the flame safeguard control

sights the fire from an ultraviolet

scanner located on top of the burn-

er. There will be a first stage pilot

before the main oil valve is ener-

gized. After flame is proven the

main oil valve will come on. If flame

is not proven, it goes into safety

shut down. Note: 20 BHP has only

one stage. 60-100 BHP come stan-

dardly with display module.

f) Reset by depressing the button

on the flame safeguard control. If

boiler does not respond after 3

attempts, contact your authorized

Fulton Representative.

g) The main air control shutter is

adjacent to the oil pump and should

be adjusted so as to give a clean

burning fire without excess air being

delivered to the burner.

h) The secondary air control is an L

type handle located on the top of

the burner scroll which controls the

amount of the air that is delivered

over the oil nozzle. This should be

adjusted to keep the fire from back-

ing up into the blast tube.

i) Make sure the secondary air

damper is locked.

j) Lock into position the main air

control shutter.

k) After the oil has been ignited in

the burner, it will be controlled

through an on/off cycle by the pres-

sure control in the panel box which

should be adjusted to suit the boiler

application.

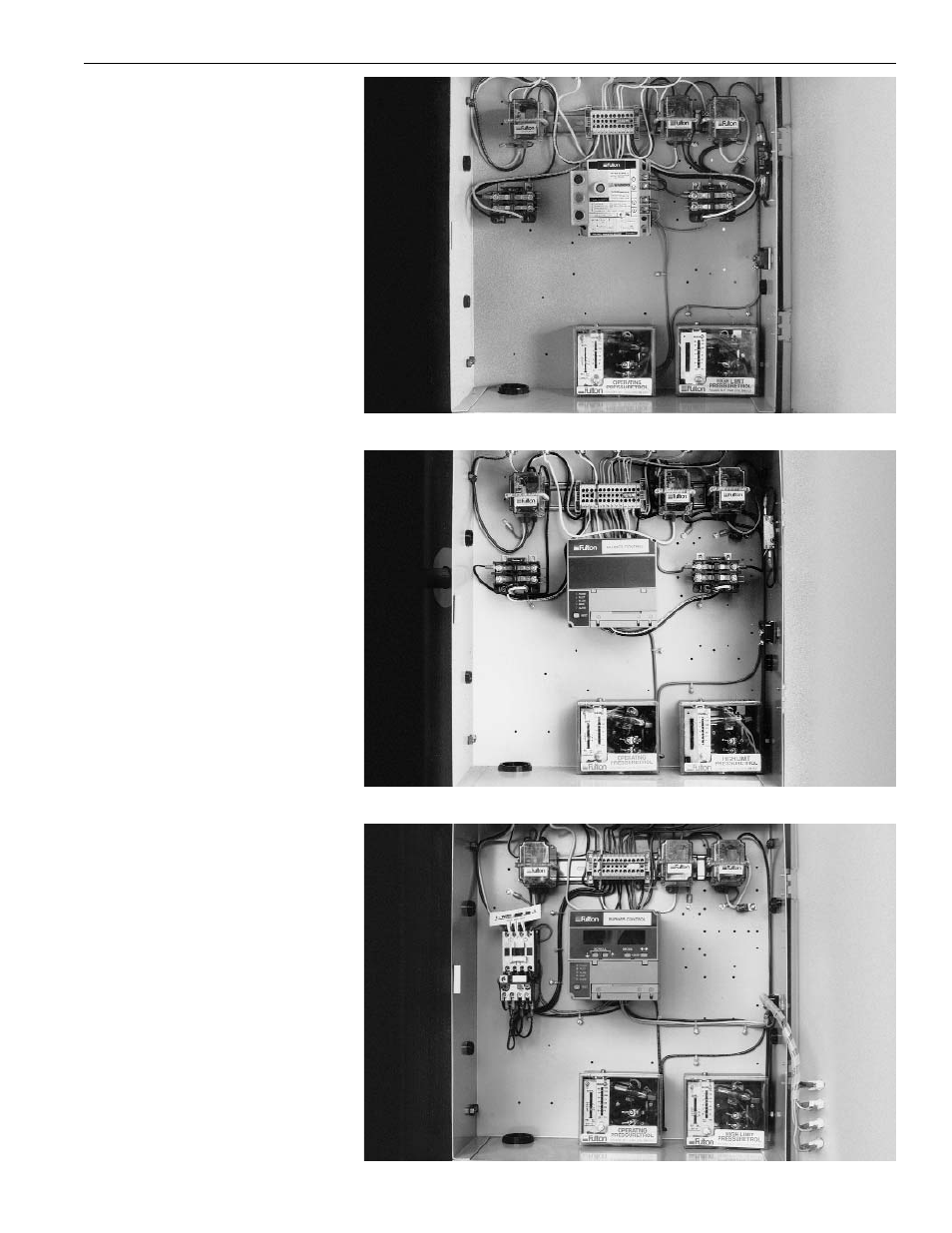

4-15 HP with 8184 relay

20-50 HP with 7895

60 HP with 7800 with display module

22-O 4/00