Maintenance – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 41

Recommended Daily

Maintenance Schedule

a) The following procedures should

be carried out daily. They are

designed to prevent the build up

of scale, silt, or sludge in the bot-

tom of the boiler and in the pipes

leading to the water gauge. In

addition to these procedures, the

advice of a water treatment suppli-

er should be sought and followed.

An ASME Section VIII blow off

receptacle must be provided for the

appropriate pressure.

b) Blow down the boiler each

morning by starting the boiler and

generating not more than 10 PSI

(.703 kg/cm

2

)of steam, then shut off

burner. Turn on tap water to blow-

off separator, then open the boiler

blow off valve for approximately 10

seconds, then close the valve. Shut

off tap water to blow-off separator.

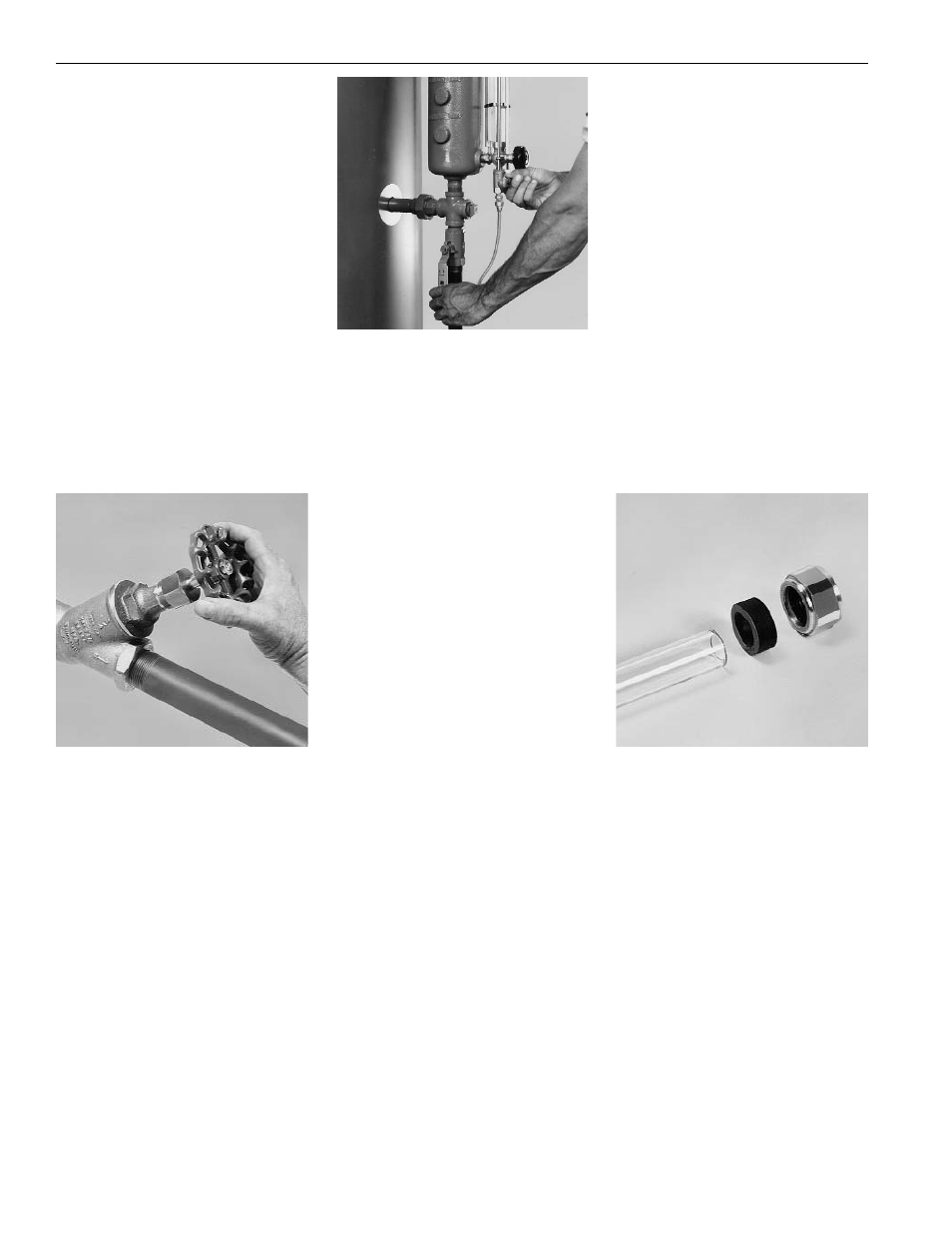

Blow down boiler daily; shown is the

blow down "Y" valve

NOTE

If the boiler is being operated

automatically on a time clock, the

blow off operation may be done

once during the working day and

once at the end of the day when

at 10 PSIG or less.

c) Blow down water column each

morning when boiler is at 10 PSIG

by opening the water column and

the water gauge blow off valves for

approximately 5 seconds, then

close the valves.

Blow down water column each morn-

ing by opening the water column and

the water gauge blow-off valves

d) If the feed water is being treated

by compounds, make sure that this

treatment is carried out carefully

and according to the specific manu-

facturer's instructions.

NOTE

Fulton recommends that the

feedwater treatment should be

added between the pump and the

boiler.

e) When first starting the boiler

each day, make sure ignition and

burner are working properly.

f) Check water level in sight glass.

g) Check to be sure feed water

pump is working.

h) For float type water level control,

blow-down float chamber.

Recommended Weekly

Maintenance Schedule

a) Check that the low water cut-off

relay is operating correctly

in the following manner:

1) Make sure that the boiler is cool

with little or no pressure showing on

the steam pressure gauge.

2) With the burner operating, open

the boiler blow off valve. When the

water drops below the required

level (note the level in the water

gauge glass) the burner should shut

off; this is when the water level falls

below the low water electrode in the

water column assembly and/or the

boiler shell. Manual reset of low

water relay is required.

Recommended Monthly

Maintenance Schedule

WARNING

Make sure main power switch is

off before starting work.

a) Clean the water gauge glass.

Caution

Do not clean the gauge or gauge

glass while pressurized or in

operation.

1) Clean the water gauge glass

using a commercial non-abrasive

glass cleaner. Use diluted acids

such as hydrochloric (muriatic) acid

when regular cleaners do not seem

to work. Do not use wire brushes

or any other abrasive materials

which could scratch the glass. If

any leakage is evident, replace the

gaskets.

Clean glass; replace gaskets

if leaking

2) Always replace the gauge glass

protector which is standard on all

Fulton Boilers.

b) Clean water pump strainers.

c) Check scanner.

d) Check starter contacts. Burned

or pitted contacts should be

replaced. Do not use sand paper or

file to clean.

e) Clean water traps and strainers

in fuel lines.

f) Check operation of all steam

traps on condensate return system.

Maintenance

31-O 4/00