Description/instructions – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 24

Electrical Requirements

a) Connect wiring as shown in

the wiring diagram which is fur-

nished inside the electrical control

panel box.

b) Be sure to install a fused discon-

nect for the blower and/or pump..

The disconnect should be installed

in compliance with the NEC

(National Electric Code) and all local

codes.

c) Connections for an optional

audible alarm are provided in the

control panel and are clearly indicat-

ed on the diagram.

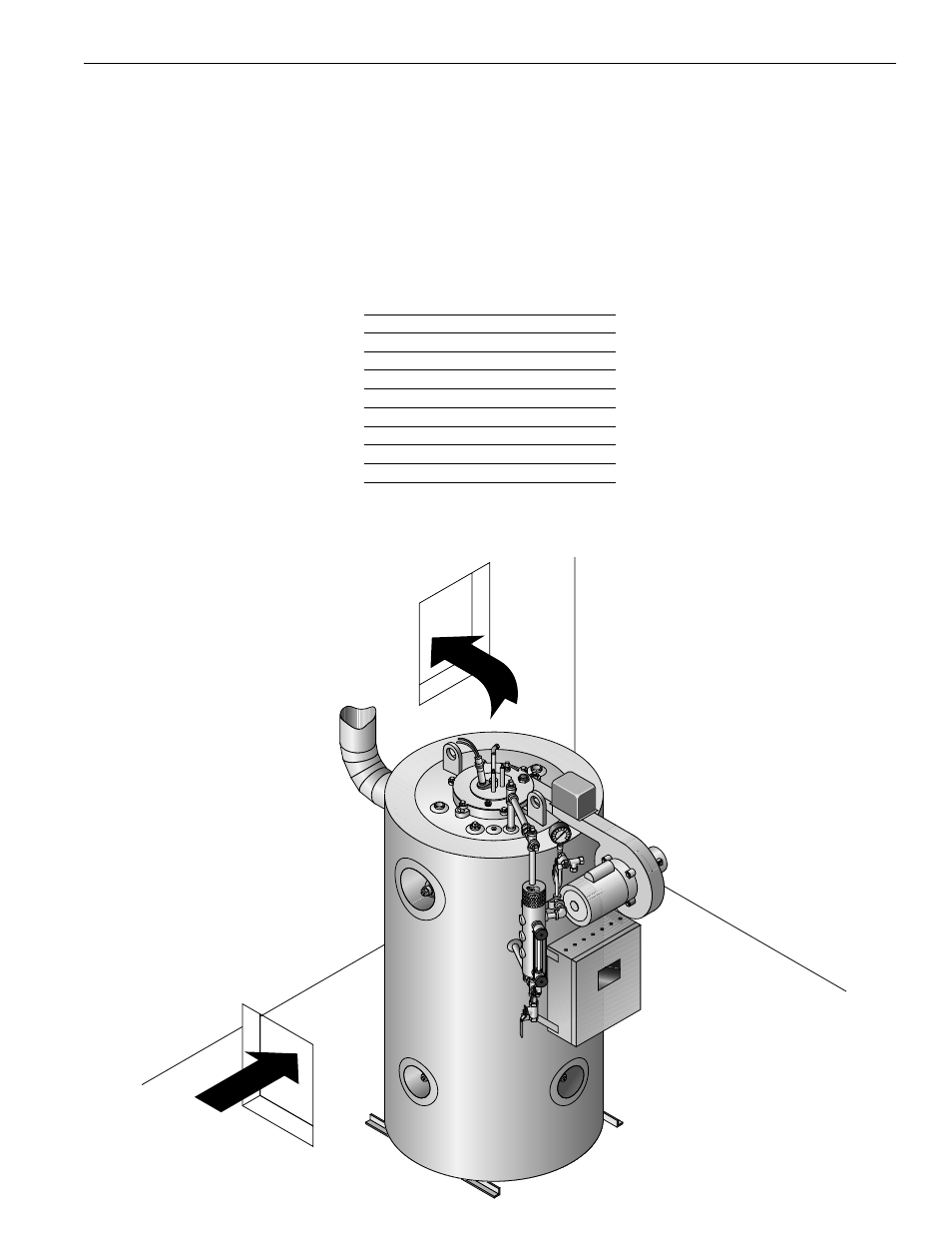

Make Up Air Supply for Boiler

Room

a) It is most important to provide

free access of air to the boiler. To

burn fuel properly, it requires one

square inch opening of fresh air for

every 3,000 BTU input of fuel.

(6.4cm

2

for every 56 Kcal).

b) Proper ventilation of the boiler

room is essential for good combus-

tion. Install two make up air open-

ings, one at a low level (24” or

610mm from floor) and one at a

higher level in the boiler room

wall.This will provide a flow of air to

exhaust the hot air from the boiler

room.

c) The following openings are

recommended for each size boiler:

Make Up Air Openings

BHP

FT

2

M

2

4

1 .09

6

1

.09

10

1 .09

15

1.5 .14

20

4

.37

30

4

.37

40

5

.46

50

5

.46

60

7.5

.69

Be sure total BHP = proper make

up air opening size. For instance

if you have three 10 BHP boilers,

it is a total BHP of 30, and the 30

BHP make up air opening size is

recommended.

NOTE

These measurements are subject

to state and local regulations. The

installation of exhaust fans in a boil-

er room Is not recommended. An

exhaust fan, or similar equipment

can create down draft in the stack or

restrict the burner’s air supply

which will result In poor combustion.

It is essential that only fresh air is

allowed to enter the combustion air

system. Foreign substances, such

as combustible volatiles and lint, in

the combustion system can create

hazardous conditions.

Description/Instructions

16-O 4/00