Maintenance – Fulton Classic ICX or FB-F Vertical Tubeless Boilers (Steam) Oil Fired User Manual

Page 40

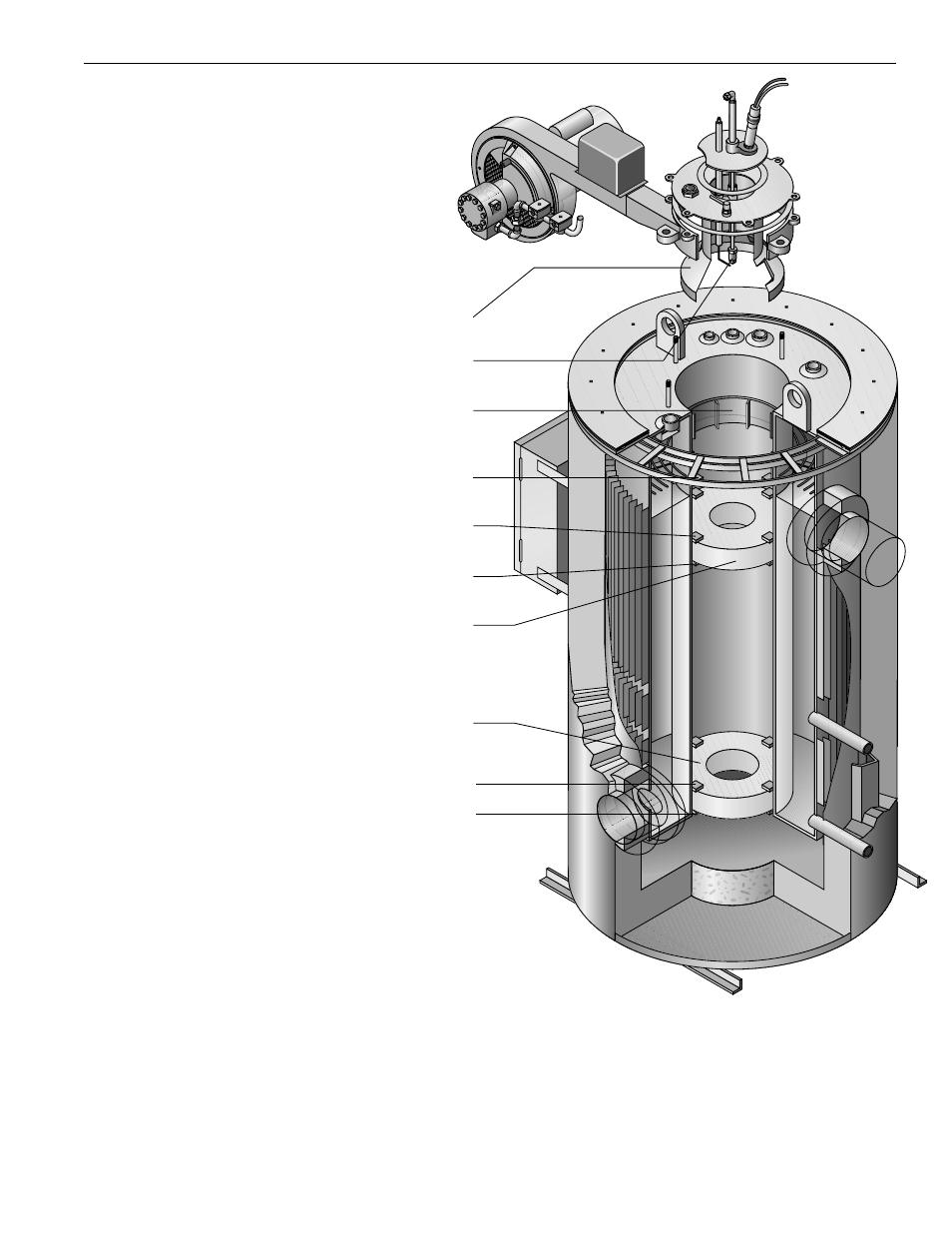

Furnace Refractory Replacement

Procedure

a) Remove the burner plate and top

plate assembly up and out of the

scroll assembly.

b) Remove the stainless steel com-

bustion ring from the furnace.

c) Remove the clean-out plugs from

the bottom sides of the boiler.

4-15 HP boilers have one cleanout

plug located at the bottom of the

boiler directly below the panel box.

20-60 HP boilers have one cleanout

plug located at the bottom of the

boiler to the right side of the panel

box.

d) Break off the top holding clips

that were used to keep the refracto-

ry in position during shipping. The

4-50 HP boilers also have holding

clips beneath the top refractory.

There is no need to cut the holding

clips located beneath the top refrac-

tory as the refractory may be rotated

to avoid these clips during installa-

tion of the lower refractory. The

60 HP boiler has welded flat bars

beneath the top refractory. These

bars will have to be cut to change

the lower refractory. Rewelding of

the bars will be required prior to

installation of the top refractory. For

the lower refractory you will also

need to break off the top holding

clips that were used to keep the

refractory in position during ship-

ment.

e) Break up the top and/or bottom

refractories and remove the pieces

from the boiler through the clean-out

plugs.

NOTE

If only the top refractory is to be

changed, the bottom refractory

need not be broken.

f) Round and bevel the outer edges

of the new refractories.

g) The bottom refractory has the

largest hole, while the top refractory

has the smallest.

h) Lower the bottom refractory

down the furnace with wire fastened

around the refractory in three posi-

tions. When the refractory is close

to position, it can be tipped maneu-

vering the wire to drop it flat on the

holding clips. If the refractory will

not tip, it may have to be removed

and again rounded and beveled.

i) Install the top refractory in the

same manner as the bottom refrac-

tory. When installed the outer edges

must be sealed with insulcrete - a

castable refractory mix available

from the Fulton factory.

It is not necessary to reinstall the

shipping clips.

j) Install the stainless steel combus-

tion ring, burner assembly, and

clean out plug.

k) normal operation can be

resumed immediately.

Maintenance

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

Stainless Steel Ring

Supporting Clips

Air

Deflector

Oil Nozzle

Assembly

Stainless Steel

Combustion

Chamber

Ring

Stainless Steel

Supporting Clips

Top Castable

Refractory

Bottom

Castable

Refractory

Stainless Steel

Supporting Clips

Holding Clips For

Shipping Only

Holding Clips For

Shipping Only

30-O 4/00