Operation, Procedure for first shutdown – Fulton Alliance (FT-HC) Horizontal Coil Thermal Fluid (hot oil) Heater User Manual

Page 63

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 3

FTHC-IOM-2012-1001

OPERATION

3-27

!

WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

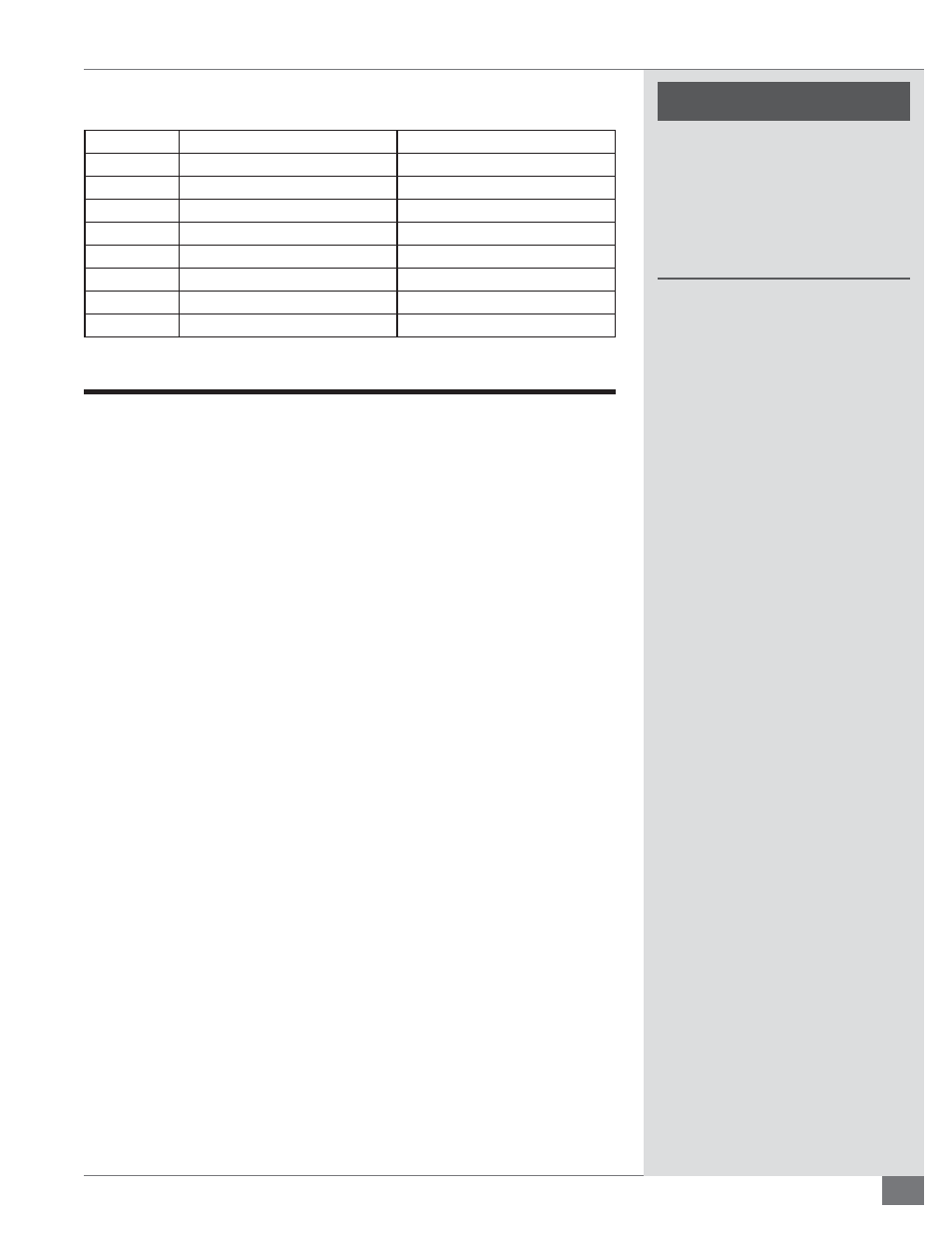

TABLE 9 - REQUIRED PRESSURE DROP ACROSS THE HEATER

Model

Recommended GPM (schedule 40)

Pressure Drop PSI

FT-0240-HC

150

30

FT-0400-HC

300

25

FT-0600-HC

400

26

FT-0800-HC

600

26

FT-1000-HC

850

30

FT-1200-HC

1000

27

FT-1600-HC

1200

11

FT-2000-HC

1500

11

Procedure for First Shutdown

The heater system should be shut down after no more than 24 hours of

operation at full operating temperature. At this time, the following maintenance

items will need to be completed to meet warranty conditions.

1. While pump is still at operating temperature, align circulating pump(s) to

pump manufacturer’s specifi cations. This should be done by means of a

dial indicator.

2. Isolate Y-strainer(s) in system and clean regardless of pump suction

pressure. Make sure that the temperature is low enough to handle safely

or provision has been made to handle materials at high temperature.

Generally, temperatures below 150°F (65.5°C) are acceptable to perform

operation with regular work gloves.

3. With piping system cooled to ambient temperature, torque all bolts on

skid and throughout system to gasket manufacturer’s specifi cations using

proper fl ange torquing practices such as incremental torque increases, star

pattern, etc. Refer to torque specifi cations in Tables 5 - 8.

4. Visually inspect all thread fi ttings and valve packings. Repair leaks and

tighten valve packings to the point of stopping leak.

5. Upon putting unit back into operation, check all gauge readings. Note any

discrepancies and contact Fulton.