Fulton Vertical Electric (FT-N) Thermal Fluid (hot oil) Heater User Manual

Page 53

Fulton Thermal Corp.*Electric Thermal Fluid Heaters Manual* Version 2010-0423

Page 53

10. Energizing the Elements

a) When the system is initially brought up to temperature, additional pipe scale and welding

slag will loosen and enter the fluid stream. This will be trapped in the strainer causing

vacuum at the pump suction. This procedure must be followed as necessary in the

course of heater operation.

b) Check safeties.

c) Place three position switch in Position “2”. Elements will begin to cycle on.

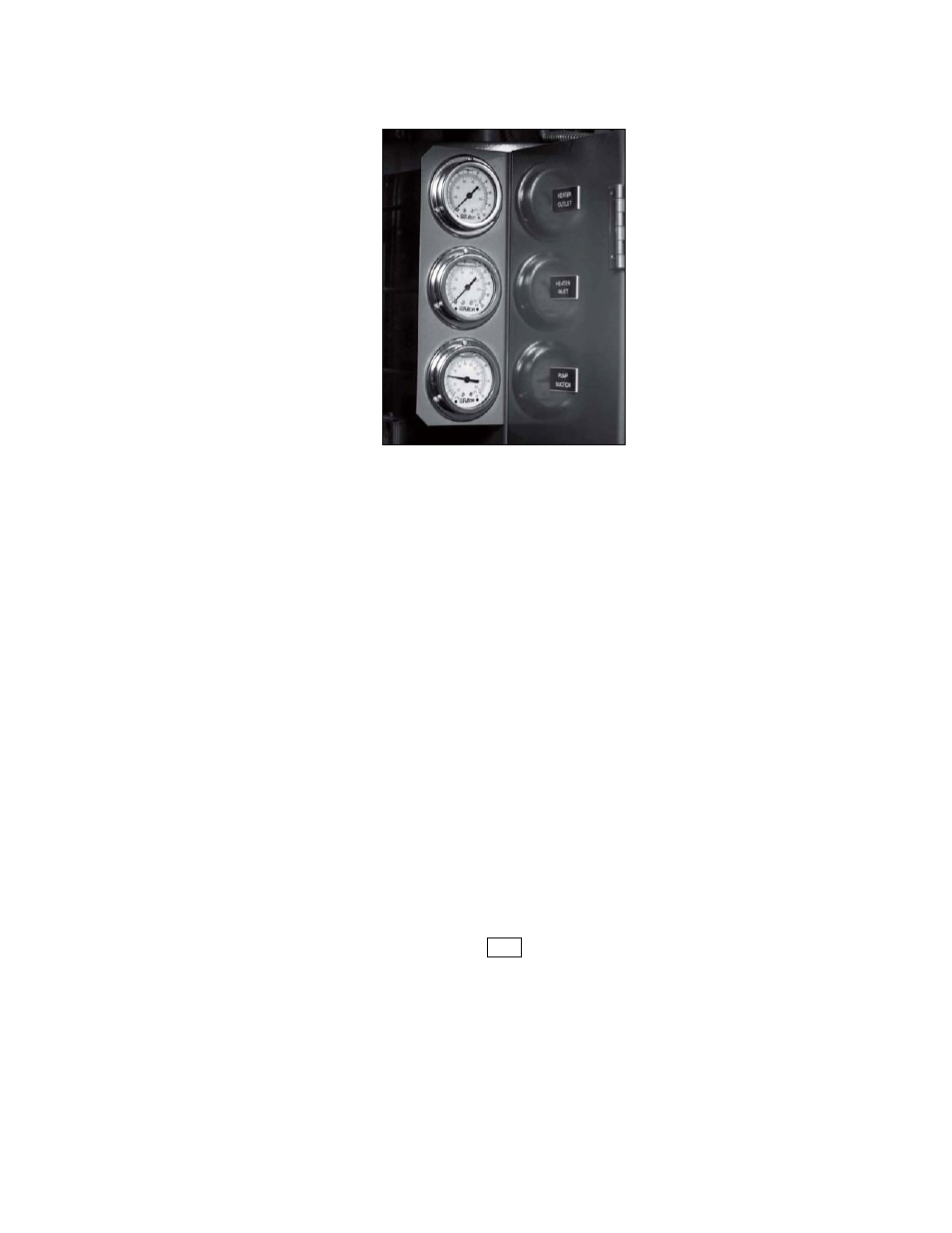

d) Check gauges indicating pump and circuit pressures. Make sure readings remain stable.

In case of pressure fluctuations, turn three position switch to Position “1”, elements will

cycle off but pump continues to circulate fluid. When pressures have stabilized, switch to

Position “2”.

e) Continue in this manner up to the maximum operating temperature. Throughout the initial

warm-up, the expansion tank and its overflow pipe must be watched to detect the

formation of froth, indicating the presence of water.

f) Water in the fluid can provide the ejection of a certain amount of fluid as soon as a

temperature of 212°F (100°C) is reached. If this occurs, a temperature of 212°F must not

be exceeded until frothing and fluid ejection have completely ceased.

Note

Flash steam may be generated at any point up to the operating temperature. Watch

for gauge fluctuations.

g) Continue bringing unit up to temperature slowly, with a temperature rise not exceeding

100°F (38°C) per hour. Do not exceed specified maximum outlet temperature. In the

absence of specific information, consult the factory before proceeding.

Pressure Gauges