Fulton Vertical Electric (FT-N) Thermal Fluid (hot oil) Heater User Manual

Page 20

Fulton Thermal Corp.*Electric Thermal Fluid Heaters Manual* Version 2010-0423

Page 20

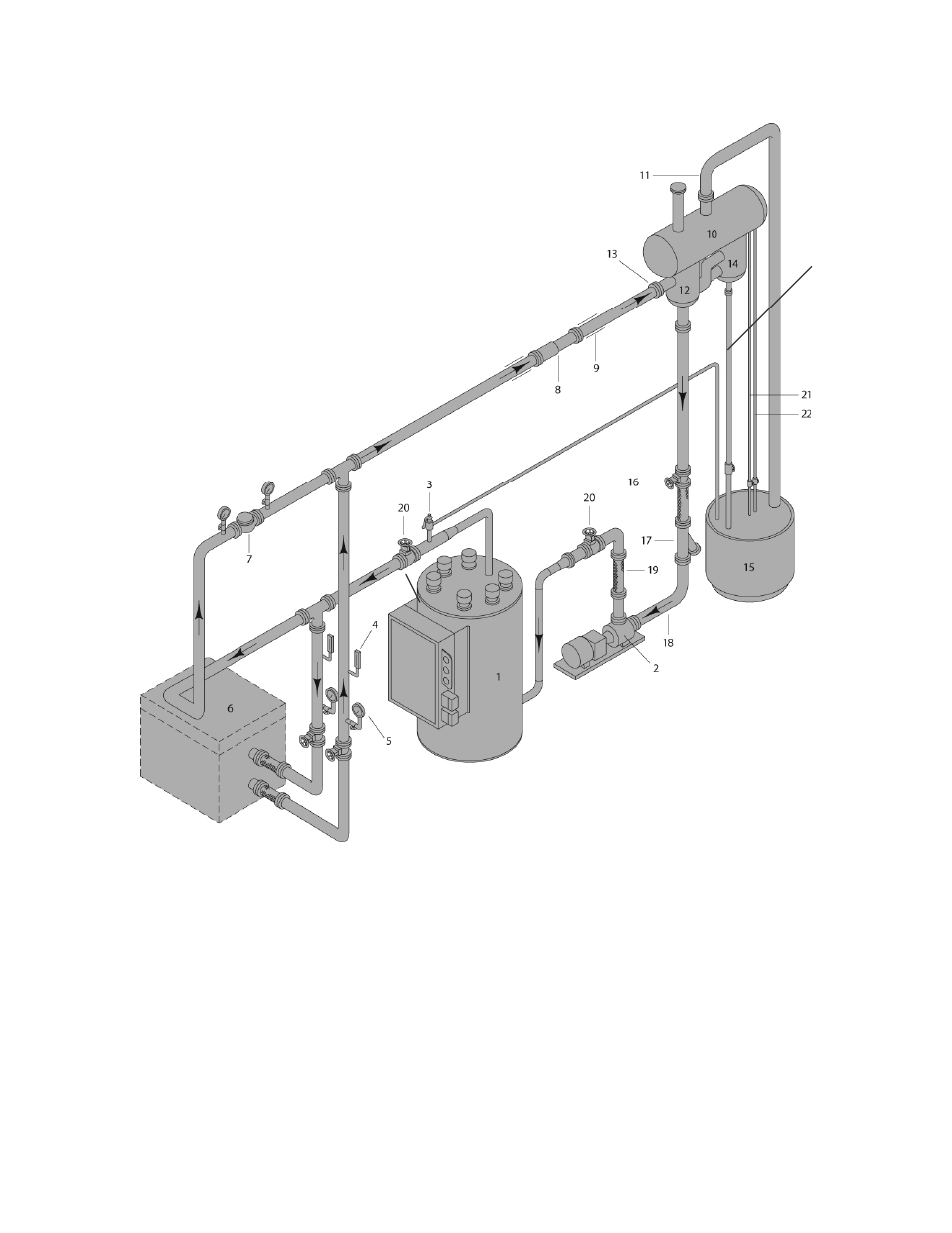

d) Typical Fulton Thermal Piping Schematic

e) Alignment

1. Proper alignment directly affects bearing, coupling, and seal life

expectancy. The pump is properly aligned before it leaves the factory.

Because the system expands in operation, pump must be realigned

when the system is at operating temperature.

2. The coupling alignment of the pump and driver must be carefully

checked for angular and axial alignment. Check pump manufacturers

instructions for these specifications. The use of a dial indicator to check

the axial and angular alignment is recommended.

20

23

1.

Thermal Fluid Heater

2.

Thermal Fluid Circulating Pump

3.

Safety Relief Valve

4. Thermometer

5. Pressure

Gauge

6.

Thermal Fluid Heated Equipment

7.

Bypass Valve to maintain full flow to heater

8.

Expansion Joints as required

9.

Anchor and Pipe Guides as required

10. Expansion

Tank

11. Vent Piping should be full size of expansion tank vent

12. Deaerator

Tank

13. Deaerator Tank inlet must be highest point of piping

14. Thermal Buffer Tank

15. Catch Tank for drain of pressure relief valve, cold seal,

expansion tank, and vent. Locate in safe area.

16. Gate

Valve

17. Strainer

18. ¾” System Fill Connection

19. Flexible Connection as necessary

20. Isolating Valve as necessary

21. Manual Low Level Test Line

22. Manual High Level Test Line

23. Buffer

Drain

Full pump design flow must be maintained at all

times thru the main piping loop. Low flow will

seriously damage heater.

Note: Manifold configuration for illustration only.

See drawing appropriate to particular model.