Fulton Vertical Electric (FT-N) Thermal Fluid (hot oil) Heater User Manual

Page 18

Fulton Thermal Corp.*Electric Thermal Fluid Heaters Manual* Version 2010-0423

Page 18

7. Circulating Pump

a) Installing the pump in accordance with the manufacturer’s specifications and these

instructions will prolong the life of the pump and contribute significantly to the successful

operation of your Fulton heater system. The pump manufacturer’s installation and

operation instructions can be found in Section 5 of this manual.

b) Location

1. The pump should be located adjacent to the heater. Its base must be

firm, level (preferably concrete), and free from vibration.

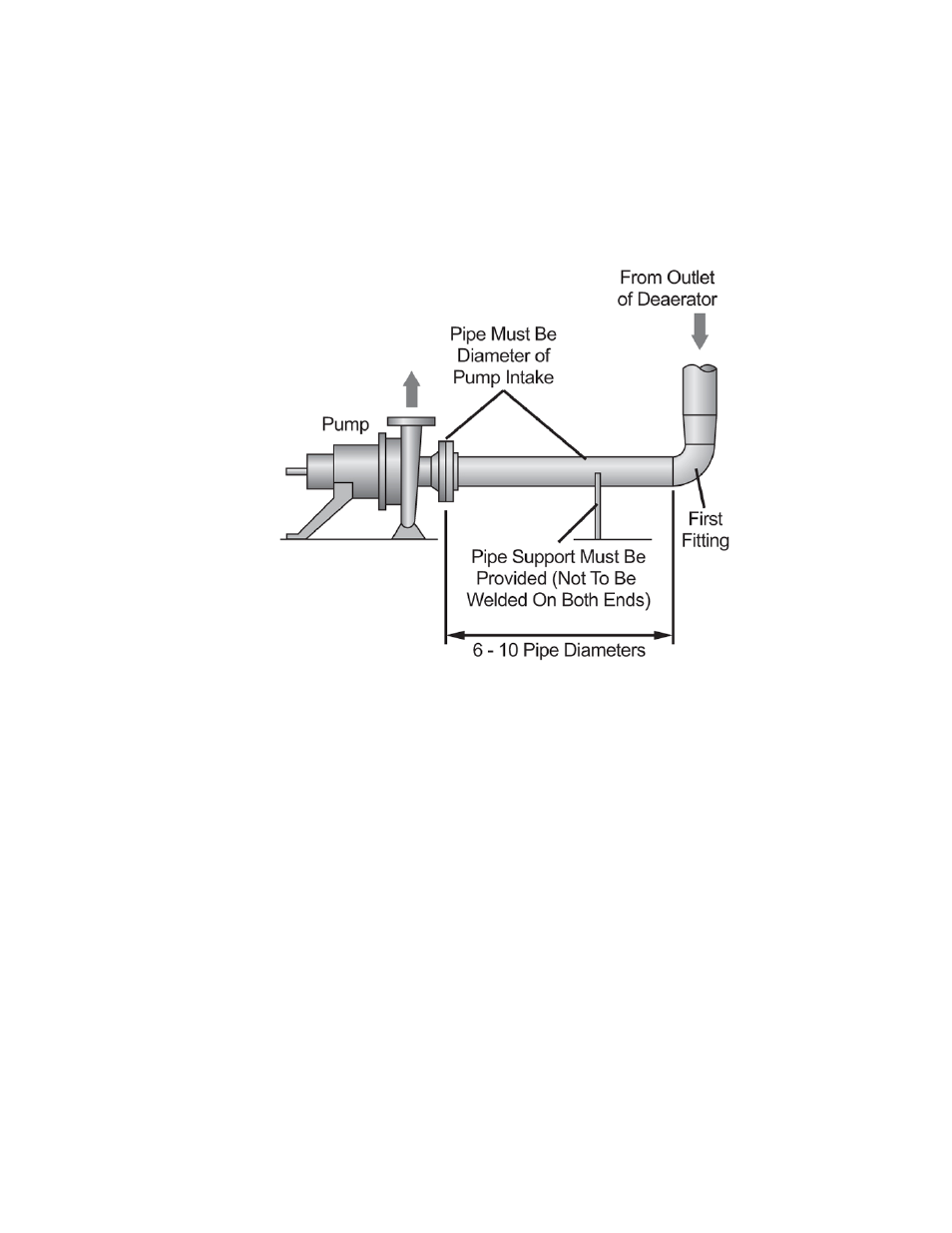

c) Connections & Piping

1. The pump should be routed as per the manufacturer’s requirements. It

should be equipped with flexible connections at the suction and

discharge sides. The primary function of these connections are to

prevent stresses due to pipe expansion from being placed on the pump

and to isolate pump vibrations from the pipe work and the heater. They

also allow for expansion and deflection of the pipe work. These

connections should be rated for high temperature since they are

considered part of the piping system.

2. The suction pipe work must be directly connected to the deaerator

section via a vertical run with as few elbows as possible, and should

contain the strainer and an isolating valve. The discharge pipe work must

be connected directly to the heater inlet, and should contain an isolating