Fulton Vertical Electric (FT-N) Thermal Fluid (hot oil) Heater User Manual

Page 34

Fulton Thermal Corp.*Electric Thermal Fluid Heaters Manual* Version 2010-0423

Page 34

where the piping is first soaked in an acid bath, then soaked in a neutralizing bath, then

given a protective oil coating.)

d) All pipes should be installed with a pitch to facilitate draining and venting.

Note

Inspect the system daily for leaking joints. Shut the system down and tighten any

leaking flanges or connects immediately.

17. System Connections

a) If screwed connections have to be made, e.g. to items of control equipment, then a

thread sealant suitable for use with fluids at elevated temperature must be used. Teflon

tape, standard pipe dope, or hemp and paste are not acceptable. Screw threads must be

carefully and accurately cut. If possible, new tools should be used. Threaded connections

larger than 1” are not to be used. It is recommended that GR5 or better tensile steel bolts

be used for all flanged joints.

Standard gaskets supplied by Fulton for operating temperatures above 650

o

F are

Flexitallic Spiral Wound.

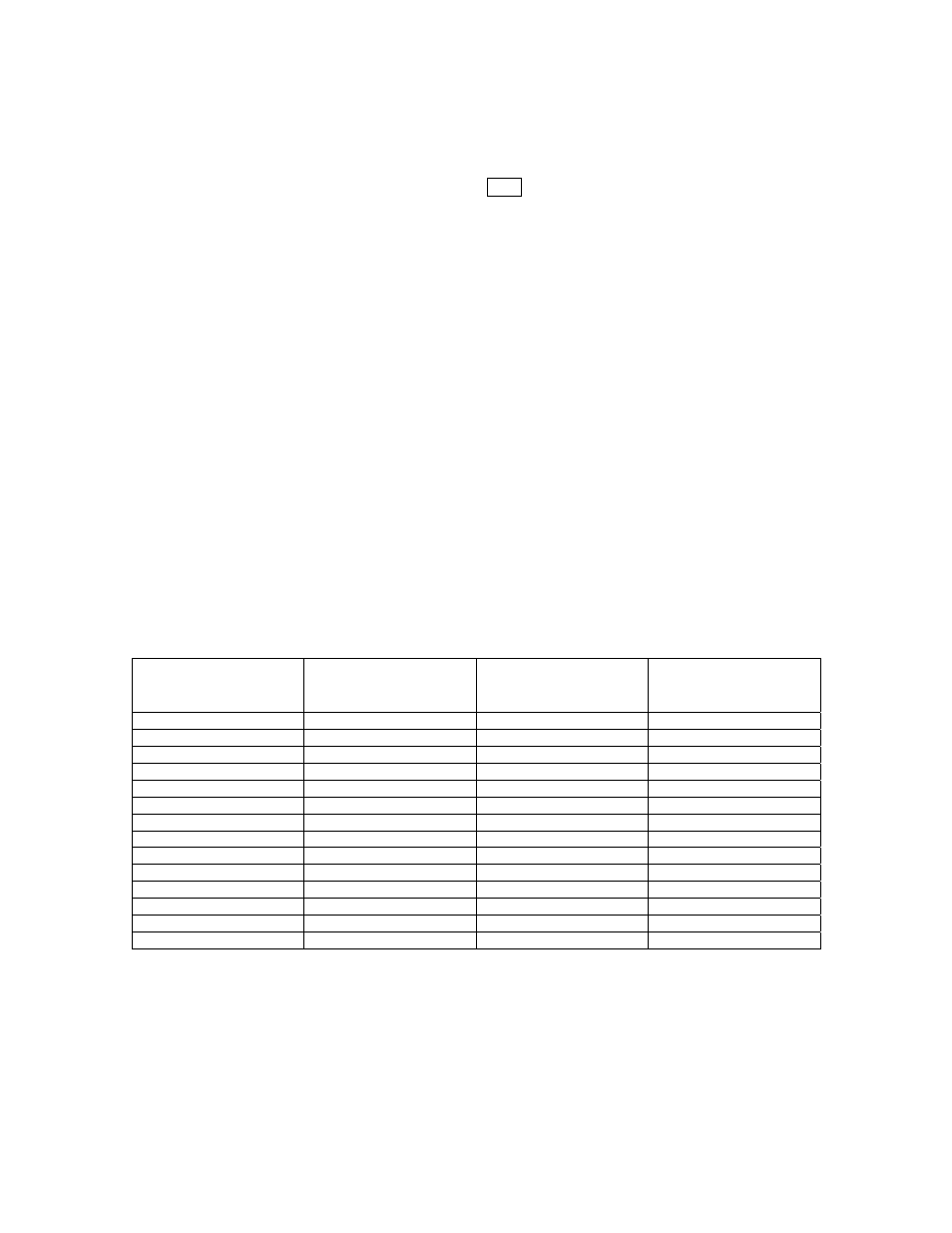

Recommended Loads for Flexitallic Spiral Wound Class 150# Gaskets

SAE Grade 5 Bolts (typical) or Equal

Nominal Flange Size

Inches

Number of Bolts

Diameter of Bolts

Inches

Preferred Torque

Required per Bolt

Ft-Lbs.

1/2 4 1/2 45

3/4 4 1/2 45

1 4 1/2

45

1 ¼

4

1/2

45

1 ½

4

1/2

45

2 4 5/8

90

2 ½

4

5/8

90

3 4 5/8

90

3 ½

8

5/8

90

4 8 5/8

90

5 8 3/4

150

6 8 3/4

150

8 8 3/4

150

10 12 7/8 240