Piping – Fulton Vertical Electric (FT-N) Thermal Fluid (hot oil) Heater User Manual

Page 33

Fulton Thermal Corp.*Electric Thermal Fluid Heaters Manual* Version 2010-0423

Page 33

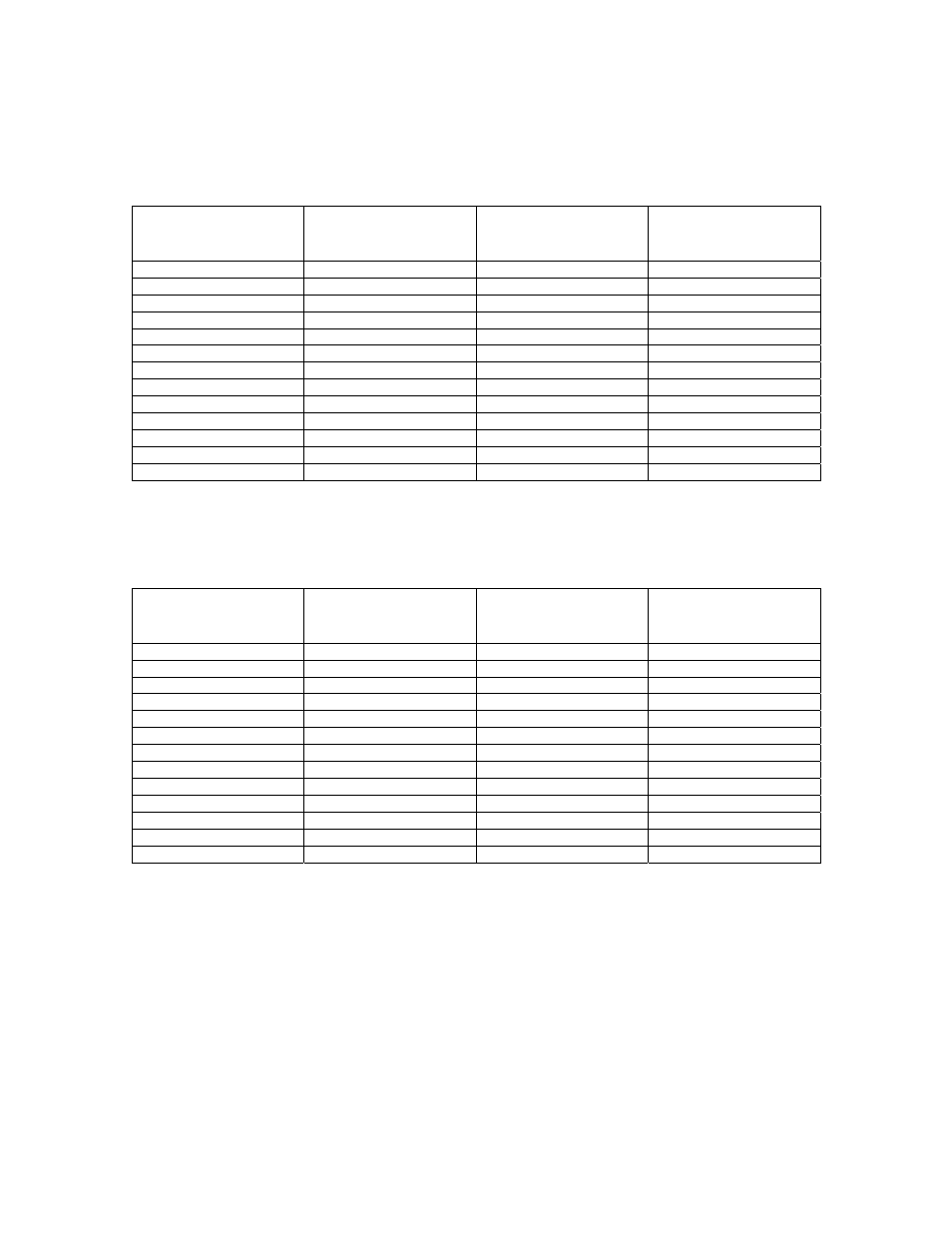

Standard gaskets supplied by Fulton are JM Clipper Elastograph for operating

temperatures up to 650

o

F.

Recommended Loads for JM Clipper elastograph 150# Gaskets

SAE Grade 5 Bolts (typical) or Equal

Nominal Flange Size

Inches

Number of Bolts

Diameter of Bolts

Inches

Preferred Torque

Required per Bolt

Ft-Lbs.

1/2 4 1/2 30

3/4 4

1/2

30

1 4

1/2

30

1 ¼

4

1/2

30

1 ½

4

1/2

30

2 4

5/8 60

2 ½

4

5/8

60

3 4

5/8

60

4 8 5/8

60

5 8 3/4

100

6 8 3/4

100

8 8 3/4

100

10 12 7/8 160

Recommended Loads for JM Clipper elastograph 300# Gaskets

SAE Grade 5 Bolts (typical) or Equal

Nominal Flange Size

Inches

Number of Bolts

Diameter of Bolts

Inches

Preferred Torque

Required per Bolt

Ft-Lbs.

1/2 4 1/2 30

3/4 4

5/8

60

1 4

5/8

60

1 ¼

4

5/8

60

1 ½

4

3/4

100

2 8

5/8 60

2 ½

8

3/4

100

3 8

3/4

100

4 8 3/4

100

5 8 3/4

100

6 12 3/4

160

8 12 7/8

245

10 16 1 160

16. Piping

a) High point bleeds are to be installed at all high points in the system piping. 1/2” x 12”

nipples welded in the top of the piping with ball valves & plugs attached are to be used.

b) It will save a considerable amount of time during the cold filtration if the thermal system

piping is cleaned prior to assembly.

c) The mill scale (the results of oxidation) on the inside of the piping as well as construction

debris can foul the oil and cause the need for the filters to be cleaned more than need be.

This can range from simply using a rag to ordering pickled pipe. (“Pickling” is a process