Maintenance – Fulton Vertical Tubeless (FT-A) Thermal Fluid (hot oil) Heater User Manual

Page 72

© The Fulton Companies 2013

MAINTENANCE

FTA-IOM-2013-0227

SECTION 4

4-12

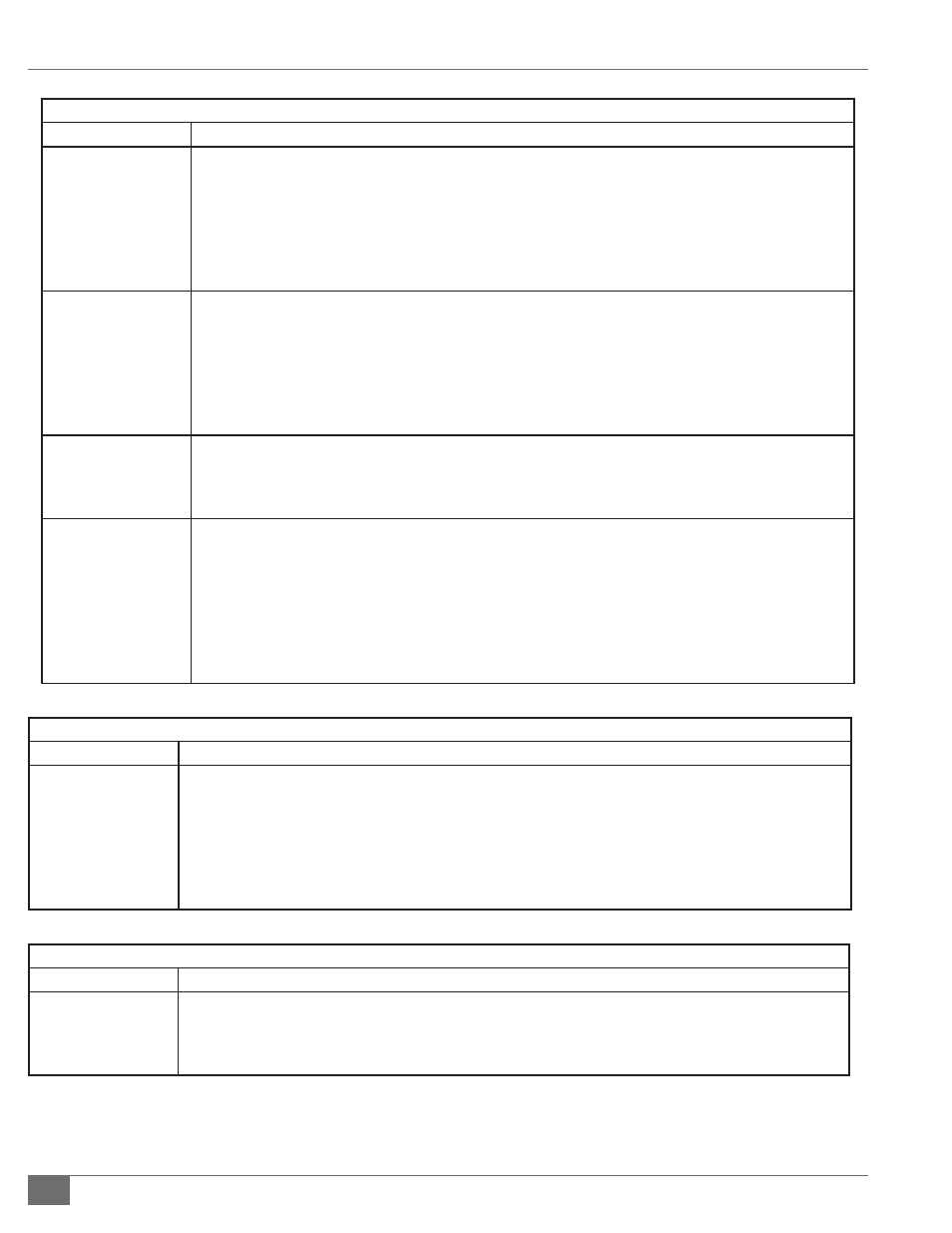

TABLE 10-C - FLOW SWITCHES TROUBLESHOOTING

Problem

Potential Remedy

An obstruction

downstream of the

Flow Switch(es)

Any obstruction downstream of the fl ow switch(es) will increase the pressure that the heater outlet sees. Any

increase in outlet pressure will result in diminished fl ow. This obstruction will generally result from an improper

valve setting.

Observe heater outlet pressure at temperature with all users / heat exchangers calling for heat (100% user). Observe

heater outlet pressure at temperature with all users / heat exchangers not calling for heat (100% bypass). Bypass

regulating valve(s) should be adjusted to equal fl ow condition through users. Call or e-mail Fulton for further details.

It may be possible that an automatic control valve has failed. If this is the case, the valve should be replaced.

Plugged circulation

pump strainer basket

A plugged strainer will result in a decrease in fl ow through the heater. High vacuums developed from plugged

strainers can also stress the seals of the pump causing the pump to fail.

A “Pump Suction” gauge is provided on Fulton Thermal skids to help determine when a strainer needs cleaning.

Generally this point is -2 psi (5 in. Hg).

If the strainer is plugged, isolate the strainer and drain being mindful of the temperature of the thermal fl uid.

Remove the strainer and clean with compressed air, high-pressure water or a cleaning solution. Replace and observe

new heater inlet pressure.

Failed circulation pump

coupling

A failed coupling will result in a decreased or no fl ow condition through the heater. The coupling can be checked

by removing the coupling guard between the pump and pump motor. The coupling should not be torn or

misshapen. If the coupling needs to be replaced, it will be necessary to re-align the circulating pump fi rst at ambient

temperature and again when it’s at operating temperature.

Cavitation of the

circulating pump

Cavitation occurs when a partial vacuum presents itself at the eye of the pump impeller due to loss of head or if any

low boiler fl ashes to gas at the impeller.

During this time, the pump impeller spins without actually circulating any thermal fl uid. If Fulton Thermal

Corporation provided the heater skid, loss of head to the pump is extremely unlikely with proper fl uid level in the

tank.

The most common low boilable in a thermal piping system is water, which needs to be boiled out at startup.

Once the system has been brought up to full operating temperature, assuming that the entire system has seen fl ow,

there should be no further occurrence of low boiler contamination apart from heat exchanger failure.

TABLE 10-D - DIFFERENTIAL PRESSURE SWITCH BREAK TROUBLESHOOTING

Problem

Potential Remedy

An obstruction

downstream of the

heater outlet

Any obstruction downstream of the fl ow switch(es) will increase the pressure that the heater outlet sees. Any increase

in outlet pressure will result in diminished fl ow. This obstruction will generally result from an improper valve setting.

Observe heater outlet pressure at temperature with all users / heat exchangers calling for heat (100% user). Observe

heater outlet pressure at temperature with all users / heat exchangers not calling for heat (100% bypass).

Bypass regulating valve(s) should be adjusted to equal fl ow condition through users. Call or e-mail Fulton for further

details.

It may be possible that an automatic control valve has failed. If this is the case, the valve should be replaced.

TABLE 10-E - CALL FOR HEAT CIRCUIT TROUBLESHOOTING

Problem

Potential Remedy

Programming Problem

Fulton has a general program for each of the temperature controllers we have used over the years. Compare your

current temperature controller program to Fulton’s general program.

See the back of this section for general programming sheets for standard Fulton heaters.

Make changes as necessary. Contact Fulton service department with any questions.