Installation – Fulton Vertical Tubeless (FT-A) Thermal Fluid (hot oil) Heater User Manual

Page 22

© The Fulton Companies 2013

INSTALLATION

FTA-IOM-2013-0227

SECTION 2

2-16

nipples welded in the top of the piping with ball valves

and plugs attached are to be used.

NOTE: It will save a considerable amount of time during the

cold fi ltration if the system piping is cleaned prior to assembly.

The mill scale (the results of oxidation) on the inside of the

piping as well as construction debris can foul the fl uid and

cause the need for the fi lters (strainers) to be cleaned more

than need be. This can range from simply using a rag to

ordering pickled pipe. (“Pickling” is a process where the piping

is fi rst soaked in an acid bath, then soaked in a neutralizing

bath, then given a protective oil coating.)

17. Install all pipes with a pitch to facilitate draining and

venting.

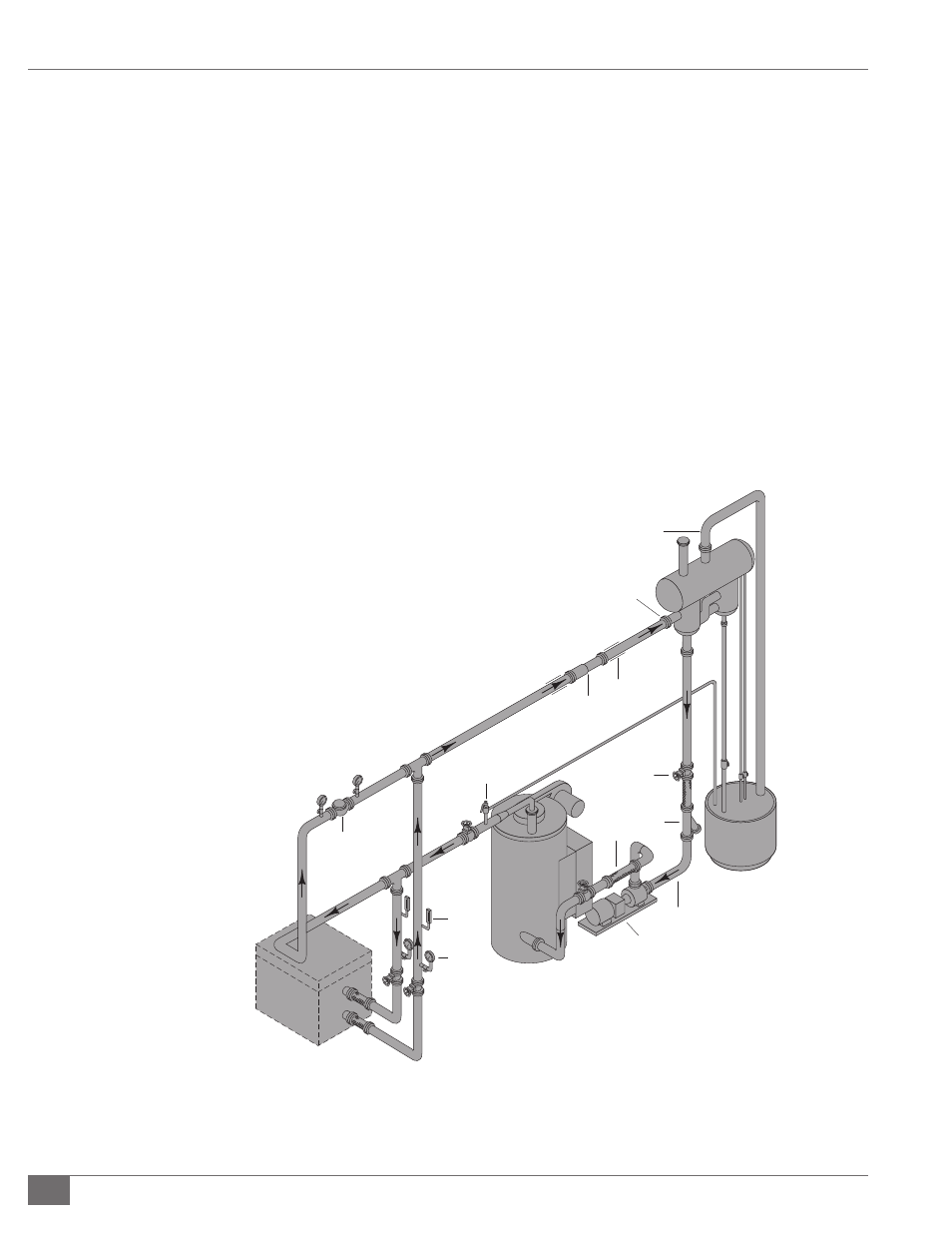

FIGURE 7 - TYPICAL THERMAL PIPING SCHEMATIC

Legend

1. Thermal Fluid Heater

2. Thermal Fluid Circulating Pump

3. Safety Relief Valve

4. Thermometer

5. Pressure Gauge

6. Thermal Fluid Heated

Equipment

7. Bypass Valve

8. Expansion Joints

9. Anchor and Pipe Guides

10. Expansion Tank

11. Vent Piping

12. Deaerator Tank

13. Deaerator Tank Inlet (must be

highest point of piping)

14. Thermal Buff er Tank

15. Catch tank (for drain of

pressure relief valve, cold seal,

expansion tank, vent)

16. Valve

17. Strainer

18. 3/4” System Fill Connection

19. Flexible Connection

7

6

3

8

9

13

11

10

12

14

15

16

17

19

18

2

1

4

5