Installation, Requirements for air cooled pumps, Requirements for water cooled pumps – Fulton Vertical Tubeless (FT-A) Thermal Fluid (hot oil) Heater User Manual

Page 28

© The Fulton Companies 2013

INSTALLATION

FTA-IOM-2013-0227

SECTION 2

2-22

Thermal fl uid is not suffi

cient lubrication for bearings.

All seals on air cooled pumps are lubricated by thermal

fl uid, therefore the pump must never be run dry, i.e.,

without thermal fl uid in it.

Filling a pump equipped with either a Grafoil packed

or mechanical seal with thermal fl uid will ensure

lubrication. However, in order to be certain that all seals

on an air cooled pump are coated with thermal fl uid,

the pump must be bled.

Grafoil packings require a run-in procedure. Typically,

pumps with these seals are shipped with four or fi ve

rings installed and several rings loose. These extra rings

must be on hand for the initial run-in procedure. See

manufacturer’s instruction manual for this procedure.

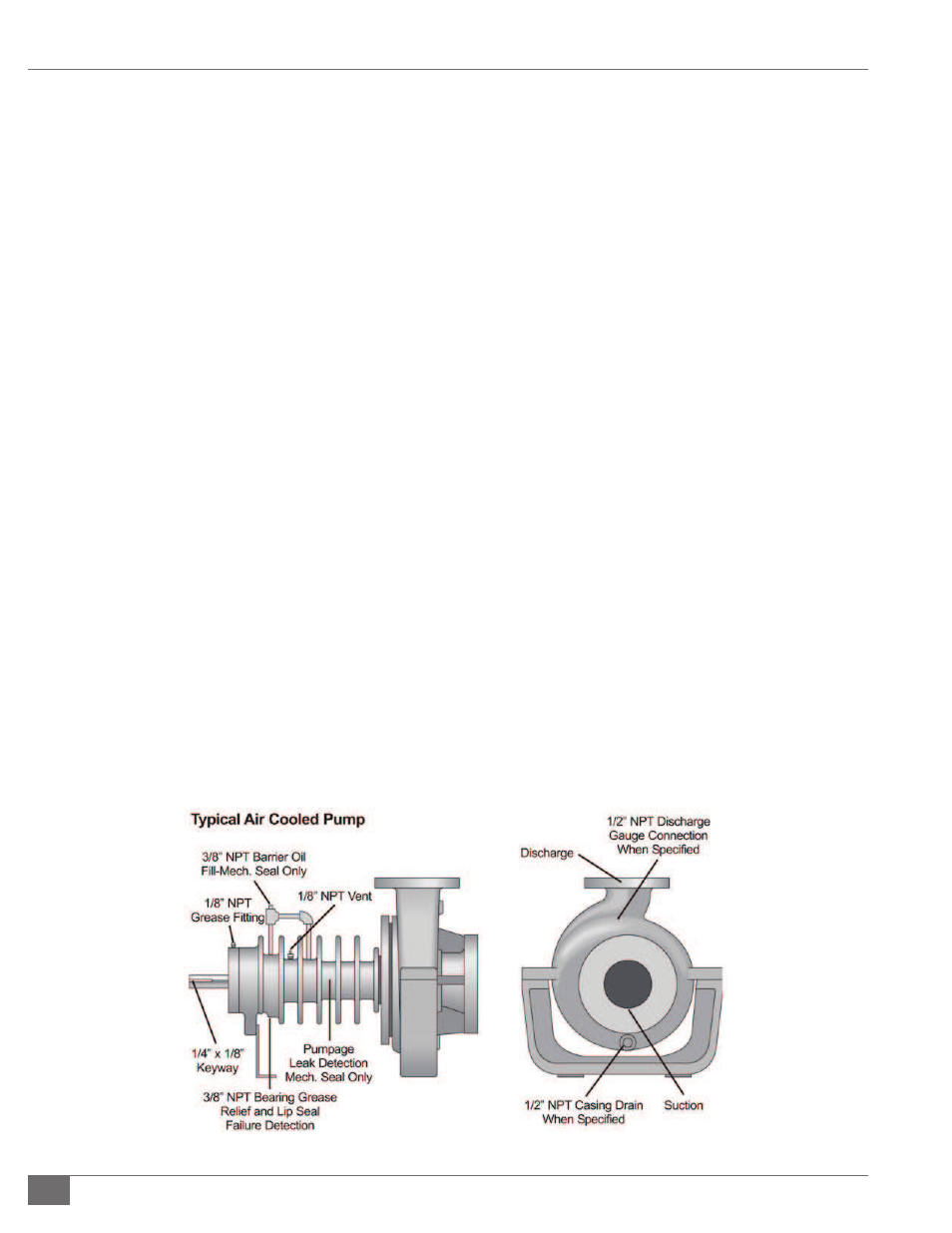

Requirements for Air Cooled Pumps

Adhere to the following for air cooled pumps (See Figure 10):

1. Allow for free air fl ow around the entire pump casing at

all times.

2. Maximum room temperature should be 100 F (38 C).

3. In no case should any part of the drive side of the pump

be insulated.

4. Maximum operating temperature for air cooled pumps

varies by manufacturer. Consult instruction manual to

verify.

FIGURE 10 - TYPICAL AIR COOLED PUMP

Requirements for Water Cooled Pumps

Adhere to the following for water cooled pumps (See Figure

11):

1. Requirements for water cooled pumps will vary with

manufacturer. Consult manufacturer’s instructions for

fl ow rate and temperature requirements.

2. Check local codes regarding disposal of hot water.

Combination Deaerator/Thermal Buff er/

Expansion Tank

Fulton Thermal’s effi

cient design combines the operation

of the expansion, deaerator, and thermal buff er tanks.

Installation is considerably simplifi ed by virtue of this

arrangement. See Figures 12 and 13.

The expansion section is vital to the thermal fl uid system.

From ambient to operating temperature, the thermal fl uid in

the system will typically expand in the range of 25% to 50%,

and a vessel capable of handling this expansion is mandatory.

The customer should confi rm the expansion rate of the

chosen fl uid and system volume.

At start up, the primary purpose of the deaerator section

is to remove all volatiles from the system to avoid pump

cavitation. The deaerator section also allows air to be vented

from the system on a continuous basis during operation

to avoid oxidation of the thermal fl uid, and removes other

volatile particles generated by the fl uid itself during system