Installation, Vent connections – Fulton Vertical Tubeless (FT-A) Thermal Fluid (hot oil) Heater User Manual

Page 32

© The Fulton Companies 2013

INSTALLATION

FTA-IOM-2013-0227

SECTION 2

2-26

!

WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

High temperature thermal fl uid,

steam, and combustible vapors

may be vented through the vent

connection on the combination

deaerator/thermal buff er/expansion

tank.

4

CAUTION

Non-code tanks cannot be pressurized

over 15 psig.

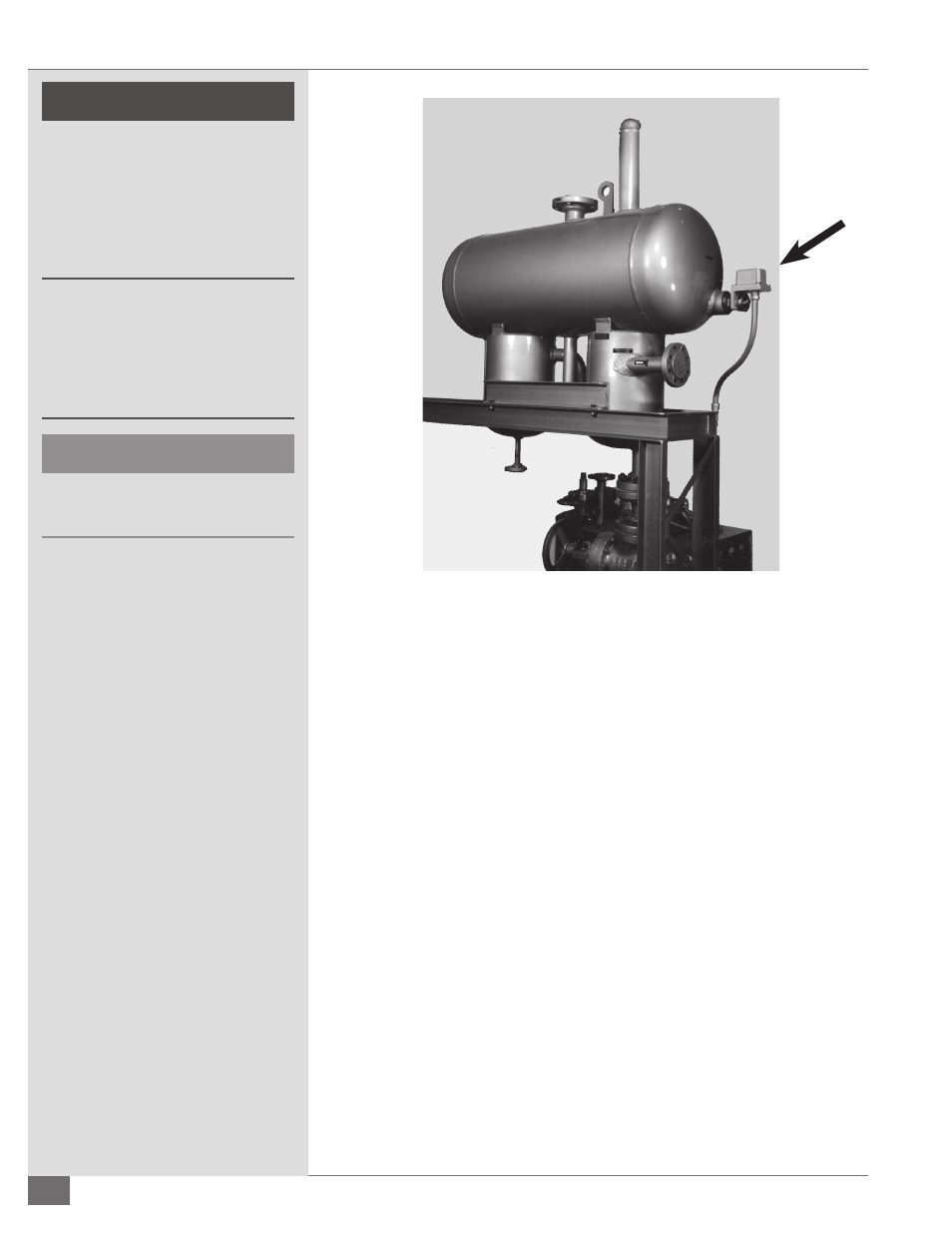

FIGURE 14 - LIQUID LEVEL SWITCH LOCATION

Vent Connections

Adhere to the following for vent connections:

1. Make vent connection in a manner that will prevent penetration of water

or foreign bodies into the tank. This connection must always terminate

in a safe, well ventilated area and has to be free of obstruction, open to

atmosphere, and arranged in such a manner that, in the event of discharge

from the system, thermal fl uid could drain into a catch tank without

danger to personnel or property.

2. Make the vent run the same size as the tank outlet. It should run pitch

down from the outlet of the tank to the catch tank.

3. If nitrogen is used on the system, the vent can be reduced to 2” (51 mm)

and should be piped with a positive closing valve at the catch tank.

4. Ensure the connection between the tank outlet and the horizontal pump

inlet is as close to a vertical drop as possible. It should have the minimum

bends and length of pipe.

5. Ensure the inlet to the deaerator is higher than or equal to the highest

point in the system, or a pressurized system must be used.

6. Field-install the liquid level switch (supplied and shipped with the unit).

This must be wired to the control panel.

7. Ensure test connections are accurate. The high and low level test