PASCO ME-9341 INTRODUCTORY ROTATIONAL APPARATUS User Manual

Page 34

Introductory Rotational Apparatus

012-03051F

30

0.15

0

5

10

15

20

TIME (SEC)

0.2

0.25

VELOCITY VS. TIME

M = -0.007076

±

0.00001571

B = 0.2472

±

0.0001405

R = -0.9997

VELOCITY

(M/S)

0

Calculations

frictional

average

h

2

(avg)

GPE (J)

d (m)

theta (rad)

torque (Nm)

torque

B.P. + pulley

0.477

-0.043

0.888

59.18

-0.00073

0.569

-0.061

0.990

65.98

-0.00092

compare

0.595

-0.069

1.022

68.11

-0.00102

-0.00104

with

0.603

-0.083

1.042

69.44

-0.00120

below

0.603

-0.093

1.048

69.84

-0.00133

B.P. only

0.575

-0.072

0.996

66.40

-0.00108

0.581

-0.101

1.006

67.07

-0.00150

-0.00132

0.599

-0.100

1.086

72.42

-0.00138

B.P. + disk

0.595

-0.108

1.042

69.47

-0.00156

-0.00156

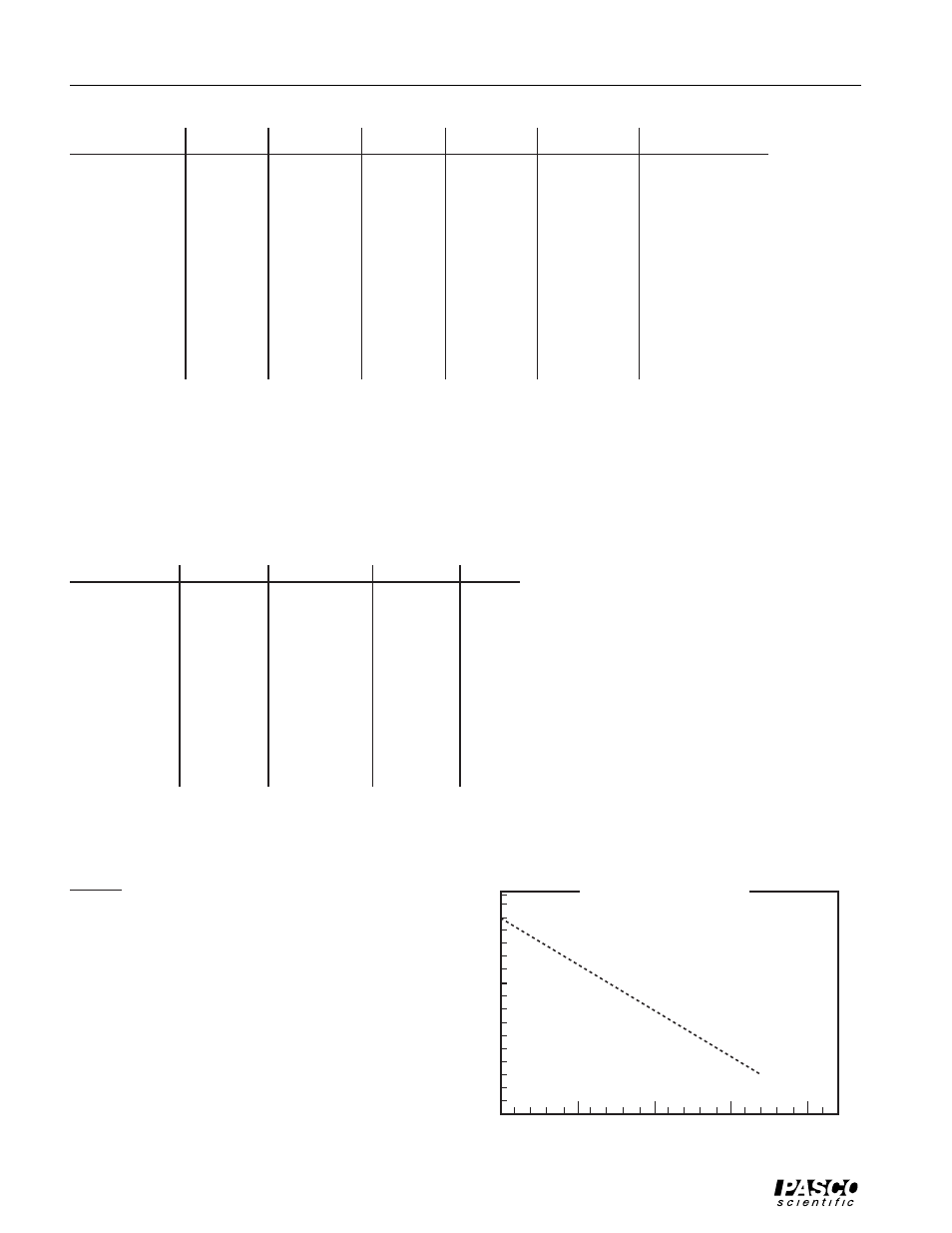

A second method of measuring the friction was used for comparison. The falling mass and attatched string were

removed and the super pulley was used with the Motion Timer program. The base plate was initially spun by

hand, and the frictional deceleration was measured as the slope of the velocity vs. time graph. (see graph) The

frictional torque was calculated from this deceleration and the known rotational inertia of the base plate.

I = 0.01

ω

o

alpha

torque

average

B.P. + pulley

6.3575

-0.11244

-0.00084

6.4890

-0.11504

-0.00086

2.8102

-0.10378

-0.00078

2.2213

-0.12181

-0.00091

2.2008

-0.08772

-0.00066

-0.00080

1.2787

-0.10370

-0.00078

0.6177

-0.09142

-0.00069

2.2157

-0.10252

-0.00077

1.7819

-0.12055

-0.00090

3.7205

-0.11370

-0.00085

There is a 23% difference in the measured friction with these two methods; mostly due to the fact that the second

method does not include the friction of the pulley used to hold up the dropping mass.

Notes

Expect a fairly wide spread of results on this

lab. The friction of the system depends on

many factors which may not be completely

controlled, and a 10% variation between

successive identical measurements is not

uncommon.