Nova-Tech PGW Series User Manual

Page 39

Page 39 of 44

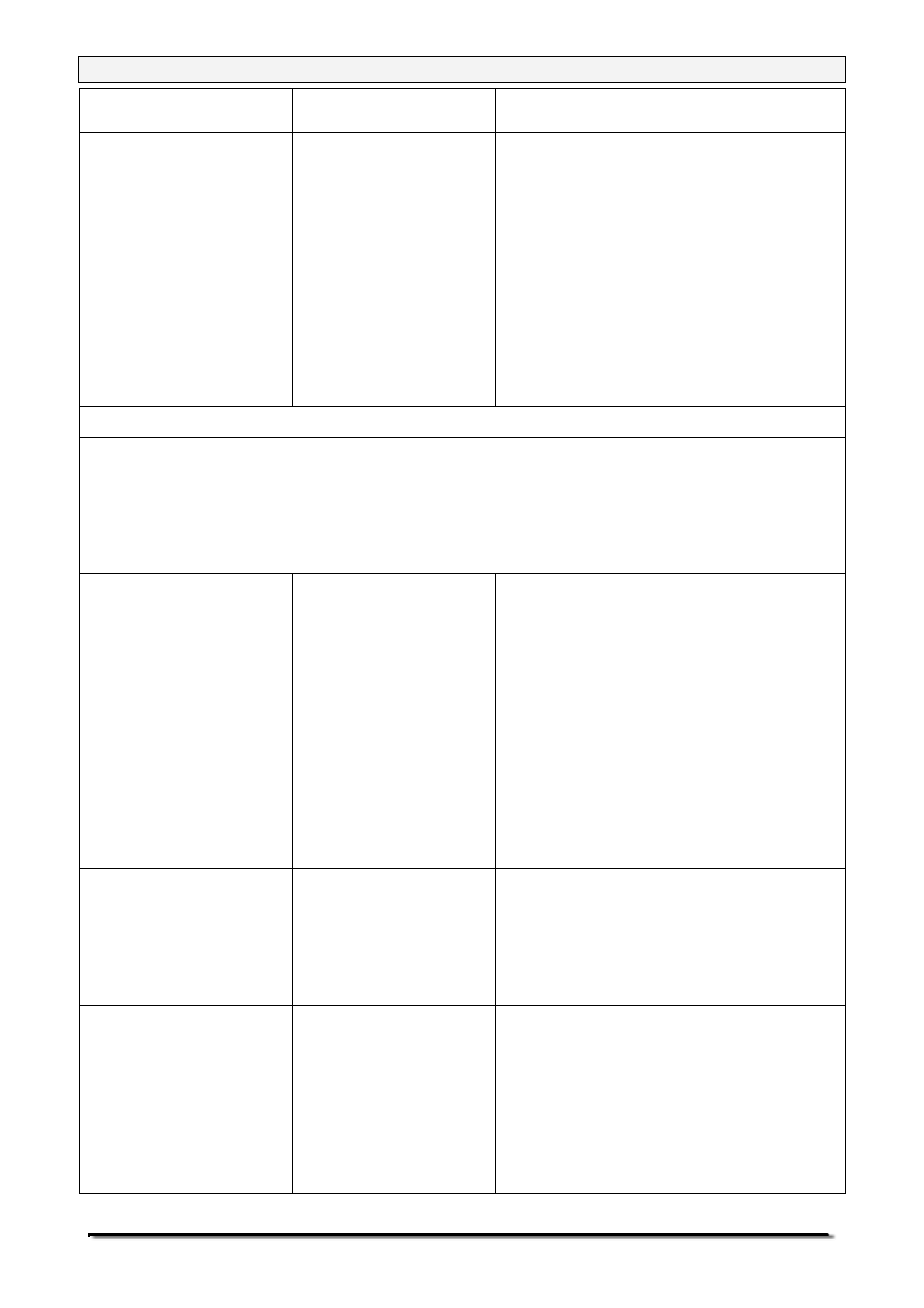

mechanics to look for sources of friction

may be needed.

Balance is very

unstable and does not

weigh correctly

Mechanical problems

Balance programming

Electronic problems

*A complete inspection of the

mechanics to look for sources of friction.

*Verify the A/D is also unstable. If the

A/D is OK then suspect the

programming of the balance. Reset

parameters, check temperature

compensation, and redo the calibration.

Some electronic problems can also

cause this. But all mechanical problems

must be resolved first.

BALANCE IS NOT ACCURATE

You must have accurate and trusted weights to test a balance. If you suspect that the

balance is not accurate then you must know your weights are accurate. A balance

calibrated using a bag of flour is not accurate even if it works OK otherwise.

Balance is not accurate

Repeatability

Eccentric loading

Linearity

Verify the balance shows the same

value when the same mass is placed on

the centre of the pan for a few tests.

Verify the balance shows the same

reading (within a tolerance depending

upon the model) when a mass is placed

at positions around the pan.

Verify the balance is acceptable

throughout the weighing range. The

balance must give acceptable readings

from low weights up to the capacity.

Poor Repeatability

Usually a mechanical

problem.

Inspect the area around the pan for hair,

dust or other obstructions,

*Inspection of the mechanics may be

needed for any possible problems.

Poor Eccentric loading

A mechanical problem Inspect the area around the pan for hair,

dust or other obstructions,

*Inspection of the mechanics may be

needed for any possible problems.

*Readjusting of the Eccentric loading is

recommended.

© Adam Equipment Company 2007